High-Flow Coolant Control Valves: Keeping Diesel Exhaust Fluid Flowing in Cold Weather

By Rachel Lahr, Director of Sales and Marketing – Commercial Vehicles, IMI Norgren

Diesel exhaust slush! That’s what you get when diesel exhaust fluid (DEF), an aqueous urea solution used in emission control systems, gets down to about 12 degrees F (-11 degrees C) or lower. In other words, a typical winter day at a mine in Wyoming, a farm in North Dakota or a construction site in New York.

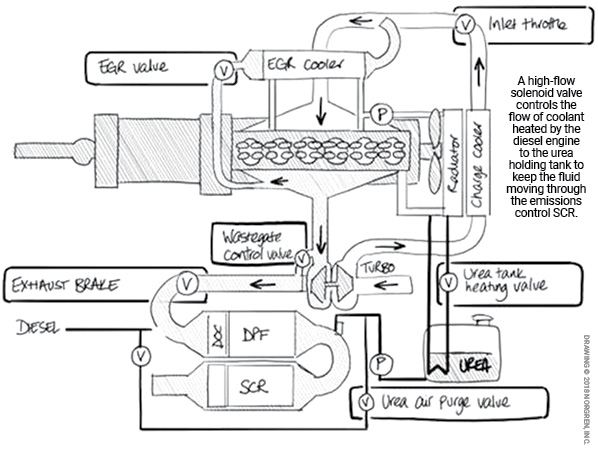

Off-highway or over-the-road, any modern medium- or heavy-duty diesel engine uses a selective catalytic reduction (SCR) system to reduce nitrogen oxide (NOX) emissions. SCRs work by injecting small amounts of DEF into the exhaust flowing from the engine. A chemical reaction of the DEF with the catalyst in the SCR converts the NOX in the exhaust to harmless nitrogen and water.

Cold Weather

The problem is that in cold weather the DEF starts to crystallize so it can’t move through the SCR. Smaller diesel engines use an electric heater to keep the DEF from freezing, but the energy cost of electric heating is prohibitive for heavy-duty engines with larger DEF tanks. Instead, designers take advantage of the coolant circuitry in these engines themselves to harness waste engine heat to warm the DEF. Tubing carries heated coolant from the engine through the urea tank, thawing the DEF back to a liquid state.

Heating Valves

But heated coolant can’t just run unchecked through the urea tank because DEF is sensitive to high temperatures as well. So, a temperature sensor in the DEF tank sends signals to a coolant control valve, like the Urea Tank Heating Valve (UTHV) from IMI Norgren, to open when the DEF is too cold and to close when it is warm enough. This regulates the flow of heated coolant through the tank, keeping the solution temperature within the optimal operating range.

No one wants to wait in the cold with the engine running for the DEF to thaw. The high flow rate of the UTHV prevents the problem of slow starts in cold temperatures by allowing the heated coolant from the engine to flow to the DEF tank as quickly as it becomes available. When the DEF reaches the correct temperature, the UTHV is designed to close gently, preventing pressure spikes caused by fluid hammer from damaging upstream components or causing premature wear.

Valve Mounting

Instead of mounting the valve in the header assembly where the sensors are, UTHVs can be mounted anywhere on the chassis. This gives designers flexibility in how they use precious space. It also means valves can be serviced or replaced simply, without the cost of disassembling the header unit. External mounting makes these valves easy to use in virtually any engine design, both for new equipment and retrofit.

IMI Norgren UTHV

The IMI Norgren UTHV combines the flexibility of a custom design with the practicality of a standard product. At its heart is a field-proven, high-flow, 2/2 normally closed diaphragm solenoid valve. Interchangeable fittings can be used to customize the valve for virtually any design and enable poka-yoke installation. Robust aluminum construction and elastomeric seals withstand the contaminants that commonly exist in coolant systems.

The IMI Norgren UTHV combines the flexibility of a custom design with the practicality of a standard product. At its heart is a field-proven, high-flow, 2/2 normally closed diaphragm solenoid valve. Interchangeable fittings can be used to customize the valve for virtually any design and enable poka-yoke installation. Robust aluminum construction and elastomeric seals withstand the contaminants that commonly exist in coolant systems.

Originally developed to meet stringent European environmental regulations, there are now close to a million IMI Norgren Urea Tank Heating Valves helping to keep the DEF flowing and reduce emissions in North America and throughout the world.

For more information: about the Urea Tank Heating Valve from IMI Norgren, visit

www.imi-precision.com/us/en/expertise/commercial-vehicles/engine