Hoists Facilitate Crane Repairs on Offshore Platform

When the diesel engine of a deck crane failed, it caused major handling problems for an offshore platform operating in the Dutch sector of the southern North Sea, problems that were solved with the use of air-operated hoists. The crane was operating at 40 meters above sea level and provided a lift capacity of 20 metric tons. Replacing the broken engine, which weighed in at approximately 2750 lbs, presented some logistic problems. The diesel engine replacement operation was successfully undertaken by Gerritsen On- & Offshore Services BV Company from its base in Amsterdam, with the work being completed in approximately one week.

As the replacement engine was too large and heavy to be ferried by helicopter, a lifting device was needed that met requirements, such as being explosion proof, lightweight, and which could easily lift the replacement safely from the supply vessel. The suitable lifting device was sourced from the J. D. Neuhaus range of air-operated hoists available in the Gerritsen rental fleet. It was a Profi 2TI model that had a lift capacity of 2 metric tons. This model is available as standard with a 3-meter lift, having an overall weight of approximately 240 lbs, including the control system. This product was easily modified to provide the 40-meter lift required onsite, involving an additional weight for the twin-chain hoist mechanism at approximately 4.5 lbs per meter run.

As the replacement engine was too large and heavy to be ferried by helicopter, a lifting device was needed that met requirements, such as being explosion proof, lightweight, and which could easily lift the replacement safely from the supply vessel. The suitable lifting device was sourced from the J. D. Neuhaus range of air-operated hoists available in the Gerritsen rental fleet. It was a Profi 2TI model that had a lift capacity of 2 metric tons. This model is available as standard with a 3-meter lift, having an overall weight of approximately 240 lbs, including the control system. This product was easily modified to provide the 40-meter lift required onsite, involving an additional weight for the twin-chain hoist mechanism at approximately 4.5 lbs per meter run.

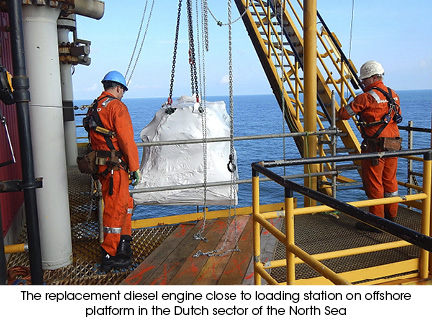

With the replacement engine and its lifting equipment being transported by a supply vessel (16 hours sea time), provision was required for an additional primary lifting unit to handle the Profi 2 TI hoist and its 40-meter drop of twin chains utilized for the major lifting operation. Once again, equipment that was light enough to be delivered to site by helicopter was selected from the Gerritsen rental fleet. This was a J. D. Neuhaus air-operated Mini hoist, providing 2200-lbs lift capacity to handle the larger and more powerful Profi hoist and its 40-meter chains. The Mini hoist, plus an appropriate beam clamp for the hoist suspension support, was helicoptered in (30 minutes air time) and mounted ready for the primary lift operation of the Profi hoist and chains utilizing a big bag container. The more powerful Profi unit was then used to replace the Mini hoist, utilizing the same beam clamp installation. The Profi hoist with a 2-metric-ton lifting capacity was then utilized to undertake the more difficult lift and location of the replacement diesel engine utilizing a sling assembly. The work was undertaken with one rig person for safety inspection, together with one rigger and three scaffolders.

With the replacement engine and its lifting equipment being transported by a supply vessel (16 hours sea time), provision was required for an additional primary lifting unit to handle the Profi 2 TI hoist and its 40-meter drop of twin chains utilized for the major lifting operation. Once again, equipment that was light enough to be delivered to site by helicopter was selected from the Gerritsen rental fleet. This was a J. D. Neuhaus air-operated Mini hoist, providing 2200-lbs lift capacity to handle the larger and more powerful Profi hoist and its 40-meter chains. The Mini hoist, plus an appropriate beam clamp for the hoist suspension support, was helicoptered in (30 minutes air time) and mounted ready for the primary lift operation of the Profi hoist and chains utilizing a big bag container. The more powerful Profi unit was then used to replace the Mini hoist, utilizing the same beam clamp installation. The Profi hoist with a 2-metric-ton lifting capacity was then utilized to undertake the more difficult lift and location of the replacement diesel engine utilizing a sling assembly. The work was undertaken with one rig person for safety inspection, together with one rigger and three scaffolders.

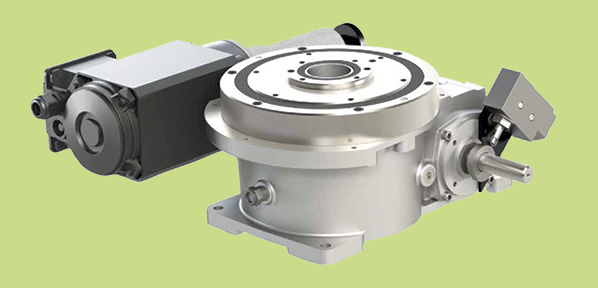

The range of air-operated hoists is universally deployable, incorporating explosion protection, and are suitable for use in hazardous areas. The Mini series is available in load capacities of 275, 550, 1100, and 2200 lbs together with a manipulator version providing for one-handed operation of lift, lower, and hoist-traverse operations. These products are explosion protected and feature an Ex classification of Ex II 3 GD IIA T4.

The range of air-operated hoists is universally deployable, incorporating explosion protection, and are suitable for use in hazardous areas. The Mini series is available in load capacities of 275, 550, 1100, and 2200 lbs together with a manipulator version providing for one-handed operation of lift, lower, and hoist-traverse operations. These products are explosion protected and feature an Ex classification of Ex II 3 GD IIA T4.

The Profi series hoists offer a more rugged build quality for heavier-duty operations and can be supplied with lift capacities from 550 lbs up to a full 100 metric tons. Duty rating of 100% and unlimited duty cycles are provided as standard, ensuring no down time and low maintenance requirements. They are supplied as standard with classification Ex II 2 GD IIA T4 / II 3 GD IIB T4, with increased spark protection to Ex II 2 GD IIB T4 and for explosion group IIC: Ex II 2 GD IIC T4. These products are insensitive to dust, humidity, and temperatures ranging from -20°C to +70°C. They also provide infinitely variable speed controls for the precise positioning of loads.