Hydraulic Solution Boosts Cost Efficiency and Extends Life Span of Wind Power Plants

Although hydraulic controls for wind power plants represent a relatively small proportion of the procurement costs compared with other components of a wind power plant, they have a crucial influence on expensive parts of plants. The rotor brakes, for instance, can be controlled very sensitively by hydraulic means, thereby protecting the gearbox, tower, and the foundation and rotor blade from being exposed to high levels of stress. This increases the life span of these expensive elements. Hydraulic components offer additional cost efficiency when they are intelligently interconnected, configured to facilitate service and maintenance, and are made of robust material.

Uncomplicated control systems that are perfectly tailored to the particular application can be implemented with HAWE Hydraulics’ products, which are based on a modular system. The philosophy of “one module per hydraulic function” is not only the basis for cost-effective controls, but offers considerable flexibility for the spatial arrangement of the components. Depending on requirements, the modules for the hydraulic functions are either mounted directly on a power pack or – if a decentralized configuration is more practical and there is sufficient space – they are distributed between several power packs.

Hydraulic functions that are featured in individual modules include rotor brake, azimuth brake, pitch adjustment, rotor blocking, nacelle roof opening, or the controls for permanently installed on-board handling cranes. The modular construction offers enormous time and cost savings if the control is subsequently modified or if redundant functions are added. To do this, there is no need to modify or redesign the basic block on the power pack. All that is required is to adapt the functional module.

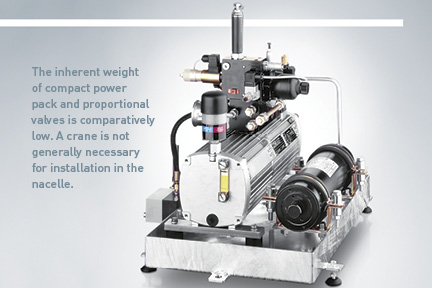

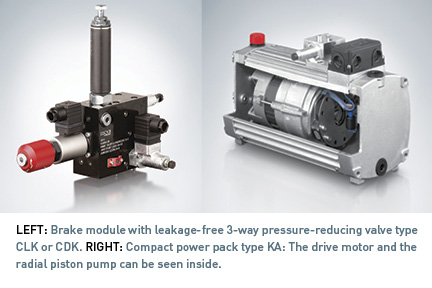

In the event of a fault, the module causing the problem can be easily identified. If it needs to be exchanged, this merely involves unscrewing four bolts and, if necessary, disconnecting the electrical connections. Time-consuming dismantling of hydraulic connections to the hydro consumers is not necessary. HAWE Hydraulics uses compact power packs for the pressurized fluid supply. These units live up to their name, requiring little space even with attachments mounted. The housing of the units doubles as the tank. This accommodates the oil-submerged motor and the feed pump in the form of a ruggedly built radial piston pump, which is constructed directly onto the motor shaft. This eliminates the need for a coupling, and the efficiency of the motor-pump combination is also improved. Furthermore, the larger cooling capacity of the hydraulic fluid compared with air cooling makes it possible to use a motor with considerably lower-rated power and smaller dimensions than a standard air-cooled motor. This also reduces energy losses when starting up. In addition, the oil-submerged design allows the housing dimensions, tank volumes, and oil requirement to be reduced to a minimum.

The compact power pack type KA is especially well suited for wind power plants. It provides a usable filling volume of two liters, which can be increased up to eleven liters with optional tank extensions. If the unit is used to supply several functions, the type KA4 is recommended because it has a usable filling volume of up to 25 liters. The compact power pack allows oil to be supplied at a pressure of up to 700 bar. It is available with all customary voltages (including 690V) and network frequencies. Depending on the arrangement of the hydraulic components and the space available in the nacelle, the unit is installed either horizontally or vertically. In environments with large temperature variations and/or high air humidity, it is advisable to equip the power pack with a silica gel filter to protect the oil against condensation. This is particularly important in the case of “cold-climate” variants.

Directional-seated valves from HAWE Hydraulics are of particular interest for the brakes and the pitch drive. They offer a high level of security since they are leak-free and thus reliably maintain the operating pressure. In accordance with the safety specifications of German Lloyd, the hydraulic unit in a wind energy plant must be able to maintain the operating pressure at a constant level for at least six hours and up to seven days if this pressure is used to operate an active brake. With its compact power packs and leak-free directional-seated valves, the hydraulics specialist can verifiably meet this requirement.

For wind power plant controls, HAWE Hydraulics uses zero-leak, seated valves similarly used for critical and safety-relevant clamping functions on machine tools. Without the use of seated valves, a larger pressure accumulator and pump unit would be necessary to properly maintain the operating pressure, due to leakage by spool valves and inadequate tightness of low-cost seat valves. The brake module with 3-way pressure control valve type CLK and integrated pressure-reducing functions is particularly well suited for the rotor brake, as well as small wind power plants up to 30 kW. This valve type is also included in the line of zero-leak seated valves and was developed for pressures up to 380 bar max. with pump pressures reaching 500 bar max. Volume flows of up to 22 l/min. are also possible.

HAWE Hydraulics manufactures all pressurized parts from steel, which gives these components both strength and resilience. Since they are also designed for higher pressures, uncommonly found in wind power plants, the hydraulic controls are extremely reliable and durable in service.

About HAWE Hydraulics North America: Since 1997, HAWE Hydraulics is a supplier of sophisticated controls to the mobile and industrial markets in North America. Based in Charlotte, N.C., the company offers application engineering, sales and service, after-sales support, and over two million dollars of product in inventory. Headquartered in Munich Germany, HAWE Hydraulik is an ISO 9001:2000 certified international supplier with a strong focus on rapidly developing niche markets.