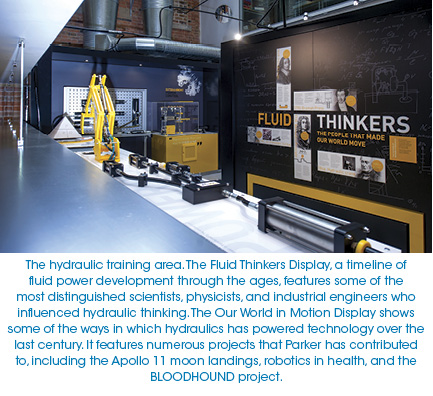

Partners in Industry and Education Unveil Hydraulic Training Area to Mark National Apprenticeship Week

A groundbreaking engineering training facility in the United Kingdom was unveiled to industry leaders by The JCB Academy and Parker Hannifin in March to mark National Apprenticeship Week.

A partnership between industry and education professionals, the facility is designed to help apprentices explore the relationship between mechanical, electrical, and fluid power. It combines academic learning with interactive challenges, including a hydraulic nutcracker, cylinder-based snooker cue, joystick-controlled backhoe, and piston push test.

The partners aim to raise the profile of apprenticeships and help meet the national engineering skills gap. Industrial dignitaries attending the launch included Jo Bamford of JCB, Transport System Catapult’s Steve Yianni, Andy Lane of SMMT, and John Savage of the National Fluid Power Centre.

On viewing the facility, Mr. Yianni commented, “The skills agenda is a critical element of success for the UK to continue to be a technological and innovation-based economy. The innovation at The JCB Academy and support of Parker Hannifin is exactly the kind of industry and education partnership that is needed for the UK to continue to prosper.”

The JCB Academy is an exciting school for students from the age of 14 who are interested in business and engineering. It is the first of a brand-new kind of school in the United Kingdom, focused on delivering high-quality engineering and business education. Its motto is “developing engineers and business leaders for the future” and aims to ensure that students have every chance to achieve success, whether they continue into further education or move to further learning in the world of work. At the academy, the curriculum and learning techniques are unique, allowing students to combine theory with practical activities and put learning into practice in purpose-built, state-of-the-art facilities. Its hours are more like business hours than normal schools and sixth-form colleges, but the curriculum encourages a structured and effective use of time.

The academy has had links with Parker for several years. In 2014, the partners discussed opportunities to give students more hands-on hydraulics experience. Parker agreed to donate a hydraulic training rig, with a view to boosting the academy’s fluid power curriculum. As work progressed, both partners saw the potential for an even bigger and better project. This led to a meeting with the principal and board of governors, and together the partners sketched ideas for a whole new learning space.

There was input from students and teachers. The students wanted to be challenged and asked questions in ways that suited their own specific age group. So Parker’s project team developed new content to meet the students’ needs inside the new learning space. The new space allows students to see and test how hydraulic, electrical, and fluid power works. There are interactive surfaces that light up, as well as group challenges and questions to complete.

Fluid Power Bench

The interactive bench includes conventional and fluid power snooker cues, a miniature backhoe, hydraulic push-touch drawers, and a “Pyramid of Power.”

Snooker Cue

This traditional snooker cue is held in place. Students push the cue to move a ball along a track and into a large square “pocket.” The pocket has a built-in collection and return area.

Fluid Power Snooker Cue

The fluid power cue features a hidden pneumatic system and simulates hydraulic power transfer from the cue handle cylinder to three ball strike cylinders. Again, balls roll along the track to the square pocket.

Nutcracker Suite

This system uses a manually operated hydraulic pump to work a nut-cracking cylinder, showing power and control. This enclosed machine system delivers a new nut from the supply hopper and drops the cracked nut into a collection bin for disposal.

Hydraulic Test Bench

Hydraulic Test Bench

The customizable hydraulic test bench allows supervised students to experience a real hydraulic system. Hoses and connectors are needed for system operation. This machinery shows the fundamentals of hydraulic testing and helps students shift from theoretical understanding to practical handling.

Pyramid of Power

Pyramid of Power

This interactive rotating display explores the importance of power in its various forms and how power is transferred from a form to another. Each face of the pyramid rotates and lights up to look at different forms of power and suggests areas of physics to explore.

Miniature Backhoe

This fully operational arm simulates an actual backhoe system, controlled through an integrated joystick.

Hydraulic System Drawers

A set of “hidden” drawers is set into the base of the fluid power bench. They feature a soft-touch open-and-close mechanism. Each drawer features questions, such as what, where, and how the parts of a hydraulic system generate, control, and deliver fluid power.

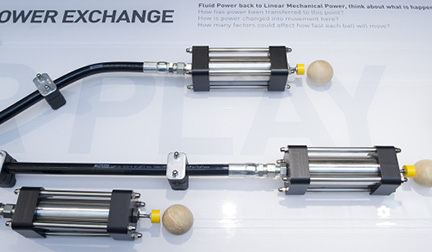

Pascal’s U-Tube Challenge

Pascal’s U-Tube Challenge

This challenge introduces the hydraulic jack principle and links to the theory behind the U-tube system. The feature contains two connected cylinders of different diameters. The cylinders are connected to a couple of plungers. Pushing the plungers shows how the system reacts in terms of force, pressure, and displacement.

Keen on acquiring a manufacturer of hydraulic cylinders and or hydraulic systems with a good customer base. Sales around $10 million.