Research to Watch: 16HS1: Hybrid MEMS Proportional Fluid Control Valve

This column will bring you the progress of the pre-competitive research being conducted at member universities that are part of the CCEFP network. This research will help give insight into the future direction of fluid power.

The Center for Compact and Efficient Fluid Power (CCEFP) holds a monthly forum, highlighting research, workforce, and special topic presentations.

CCEFP is a network of fluid-power-research laboratories, academic faculty, graduate and undergraduate students at nine universities. It is also a National Science Foundation Research Center. For more information on CCEFP, visit www.ccefp.org.

Since 2014, the National Fluid Power Association (NFPA) Foundation has supported and is helping to expand the pre-competitive fluid-power-research activities of the CCEFP, dramatically increasing the number of institutions and students impacted by its research program. For more on NFPA, visit www.nfpa.com/aboutnfpa/missionfocus.aspx.

Project Presenter and Research Assistant: Nathan Hagstrom

Project Leader: Tom Chase, Professor of Mechanical Engineering

Institution: University of Minnesota

PREMISE

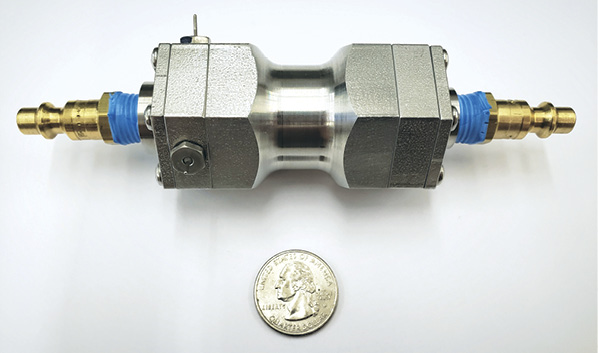

MEMS scale piezoelectric devices to create ultra-efficient miniature proportional pneumatic valves have been studied by CCEFP researchers for a number of years now, but the manufacturing challenges to overcome have proven to be quite daunting. The purpose of this project has been to accelerate the commercialization potential of this innovative approach by leveraging both MEMS-based and conventional elements in a novel “hybrid” configuration. By doing so, the resulting valve stands to not only decrease the power required to drive comparable pneumatic valves by four orders of magnitude, but also create the fastest responding pneumatic valves known.

PROGRESS

The characterization results of the first prototype have displayed the potential of piezoelectrics to improve valve performance. The valve exhibited proportional, although non-linear, flow control at all operating pressures up through the highest test pressure of 6.2 bar. It has shown to have high flow rates and turndown ratios better than 55. This functional prototype has also demonstrated mW (dynamic) and µW (static) levels of power consumption while achieving sub millisecond response times. A publication is under preparation.

NEXT STEPS

The leakage of the valve when fully closed will be reduced through modification of the sealing element. The orifice plate will be redesigned for a smaller and more efficient actuator. A new prototype, integrating design changes, will be developed. Position feedback capability will also be developed, and the contamination resistance will be explored.