Big Tires Use Intelligent Control from Sun Hydraulics

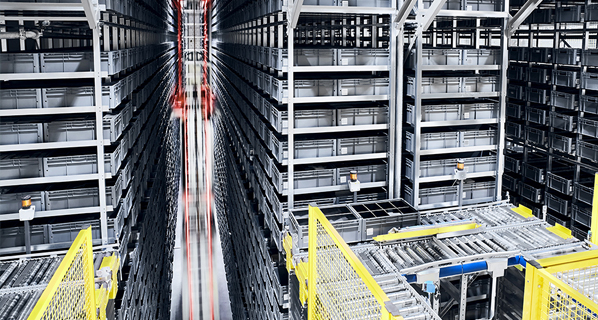

The employees at Hedweld Engineering Pty Ltd., based in NSW, Australia, have designed their new TH15000 tire handler to be heavy duty with a narrow profile that would be suitable for a normal workshop environment and also meet the demands of the many mine operators and mining service companies that maintain these enormous material-moving vehicles.

Custom Fluidpower (CFP) has a team of Mechatronics engineers at its New-castle NSW branch that worked with Hedweld to specify, design, build, and provide the entire manipulator control system comprised of Sun Hydraulics’ valves, manifolds, High-Country Tek (HCT) controllers, touch-screens, and a two-way, multi-channel radio remote unit that allowed them to turn concept into reality.

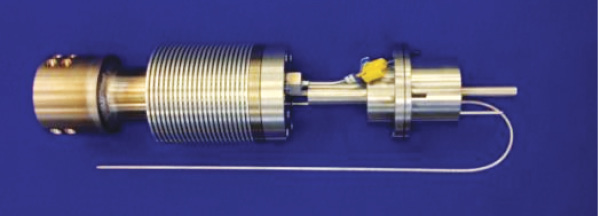

Keeping this mobile hydraulics system light, compact, and easy to service while maintaining precision handling of the giant tires within the confines of a standard workshop bay is highly dangerous, complex, and demands precise controllability that could only be met by the use of Sun’s cartridge valves and HCT controllers on all operational functions on this project.

Each machine uses four main integrated manifold packages with 36 Sun proportional valves and multiple Sun check valves, while separate counterbalance valves are used with inline manifolds mounted directly on the cylinders and wheel hub motors for extra safety.

The machine is entirely controlled by six main HCT DVC 710 modules that network to each other using the SAE J1939 digital standard to minimize wiring and ensure reliability.

Production of this machine is expected to be several per year, and with this first project proving to be such a success, Hedweld is now working with CFP on several other machines that will use products from Sun and HCT in the future.