Keep That Pressure Under Control!

![]() Machinery in a plant often operates at pressure settings higher than that actually needed to get the job done. Elevated pressure settings can cause excessive wear and tear, cause machines to consume more energy than necessary, and exacerbate the energy lost to compressed air leakage. Reducing and controlling system pressure can reduce energy consumption, as well as reduce stress on components and equipment. Install service indicators on point-of-use filters so that pressure losses can be minimized. Consider the use of tamper-resistant, locking, or even “fixed” regulators to ensure that pressure remains set at just enough to do the job and no more. The person who pays the electric bill will thank you!

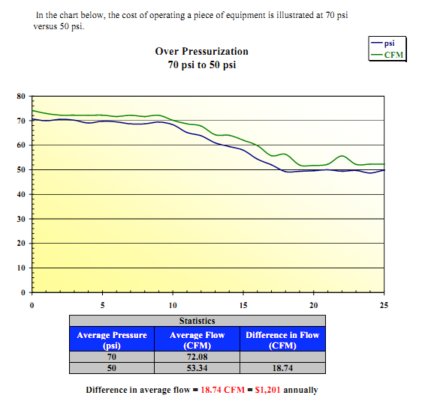

Machinery in a plant often operates at pressure settings higher than that actually needed to get the job done. Elevated pressure settings can cause excessive wear and tear, cause machines to consume more energy than necessary, and exacerbate the energy lost to compressed air leakage. Reducing and controlling system pressure can reduce energy consumption, as well as reduce stress on components and equipment. Install service indicators on point-of-use filters so that pressure losses can be minimized. Consider the use of tamper-resistant, locking, or even “fixed” regulators to ensure that pressure remains set at just enough to do the job and no more. The person who pays the electric bill will thank you!

this is applicable to hydraulic systems as well. many equipment operators have a tendency to “jack” with pressure settings because they “know” how to operate their equipment, even if they don’t know what their adjustments actually do.

“jack”= unauthorized adjustment.