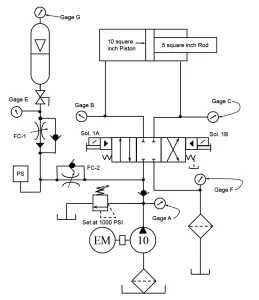

Figure It Out: Loud Noise Heard When Shutting Off a Hydraulic System

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

The attached circuit for a guillotine type press worked well for a paper mill that was using it to cut scraped 5-to-6-foot diameter paper rolls. They would bring a roll that was approximately 4 to 6 feet long and cut it in half length wise. They would then haul it over to the pulp mill that recycled it into pulp that would finally result in new rolls of paper.

The attached circuit for a guillotine type press worked well for a paper mill that was using it to cut scraped 5-to-6-foot diameter paper rolls. They would bring a roll that was approximately 4 to 6 feet long and cut it in half length wise. They would then haul it over to the pulp mill that recycled it into pulp that would finally result in new rolls of paper.

A problem developed with the hydraulic system each time they turned the system off. The electric motor and pump assembly would make a loud rumbling noise as if the pump was turning backwards at high speed and would slowly decelerate to a stop. As usual you find older systems where all the gages are missing or broken.