Low Vacuum High flow

By Daniel Pascoe

Most vacuum pick-and-place applications require a moderate vacuum level of about 20+”Hg. For example, a 40-mm diameter cup has a theoretical lifting force at this vacuum level of about 17 lbs. This is of course affected by numerous conditions such as inertia and surface type.

Most vacuum pick-and-place applications require a moderate vacuum level of about 20+”Hg. For example, a 40-mm diameter cup has a theoretical lifting force at this vacuum level of about 17 lbs. This is of course affected by numerous conditions such as inertia and surface type.

There are many options the user may choose from regarding a vacuum generation device, and in most applications where the surface is relatively non-porous, the flow rate (pump capacity) is not the primary consideration. There are many vacuum pumps (motor or pulley-driven equipment), single and multi-stage ejectors (generators) to choose from, and most of these devices offer a suitable vacuum level for pick-and-place applications. Of course the actual application will determine what exact type should be used, and in this article two are compared: compressed air-powered generators and regenerative blowers for use in low-vacuum applications requiring high flow rates—completely different technologies for completely different applications.

When using vacuum for applications that require a large volume of flow, the options for vacuum generation should be considered more carefully. In applications where material is being held down, for example, such as MDF (medium density fiber) board or plastic sheets on a CNC router (Fig. 1), the amount of vacuum required is low due to the large surface area of the parts being clamped. However, a large amount of vacuum flow is required due to the inevitable high amount of leak paths around the work piece area or through the machine’s own MDF (porous) vacuum table, where the work piece is being clamped.

Therefore, the selection criteria for correct vacuum generation equipment is clear: the user requires low vacuum and high flow.

Vacuum generation equipment of all types is able to provide this, but only a few are actually designed for this purpose. For example, a vacuum generator or venturi as shown in Fig. 2 is a very simple, low-cost vacuum generation device. Sometimes referred to as a “pump,” which it is not, the vacuum generator, venturi, or ejector (all the same device) is powered by compressed air at a pressure, depending on their design, between 40 and 90psi(g). Depending on the inlet pressure, the type of venturi nozzle(s) and the nozzle(s) diameter, the induced vacuum air flow will be determined.

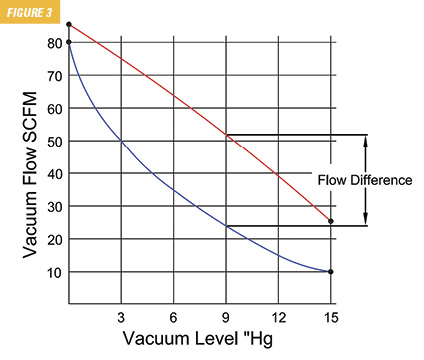

Fig. 3 shows a graph comparing a vacuum generator (Fig. 2) and a vacuum pump, which in this case is a regenerative blower (Fig. 4). As shown on the graph, both the pump (RED line) and the generator (BLUE line) start producing approximately the same amount of flow at a free air flow condition of 0″Hg (nothing attached to the inlet). As the vacuum level increases (work piece being clamped), the pump maintains a stronger air flow volume than the generator. At 9″Hg, which is a significant vacuum level for a CNC router, particularly for larger pieces, the pump has more than double the flow capacity than the generator.

Furthermore, the pump uses a 3.4-hp motor whereas the generator would require a compressor of about 7-hp to generate the compressed air required—a considerable difference.

The generator in this example has a final vacuum of about 22″Hg, whereas the pump has a maximum vacuum of only 15″Hg in comparison. But as stated before, in this application a router table rarely requires high vacuum due to the large surface areas available to hold the work piece in position.

Consequently, from this example, which is a typical performance comparison of the two technologies, the regenerative blower (Fig. 4) has a distinct advantage. Of course the air-powered generator is smaller, weighs less, has potentially a lower cost to procure, and is more mobile, but fundamentally it is not as suitable or as efficient as the blower.

Low-vacuum/high-flow applications are very common in such tasks as the printing industry where paper is being transferred with perforated rollers, plastic film positioning plates, material conveying, grain hoppers, and as shown in Fig. 5, multiple vacuum cup handling devices. The multiple cup head shown in Fig. 5 is a good example of where high vacuum is not required. If the head is maintaining a vacuum level of only 6″Hg during the pick-up phase and there are 24 cups of Ø40 mm, then this head has a holding capacity of over 126 lbs.—more than enough for the majority of applications this would be used for.

If something needs to be lifted or held down, the fundamental requirement is vacuum force. However if the seal is poor or continuously leaking, then more vacuum FLOW is required to compensate for the leakage and maintain a safe working vacuum level.

If something needs to be lifted or held down, the fundamental requirement is vacuum force. However if the seal is poor or continuously leaking, then more vacuum FLOW is required to compensate for the leakage and maintain a safe working vacuum level.

This article is intended as a general guide and as with any industrial application involving machinery choice, independent professional advice should be sought to ensure correct selection and installation.