Margin of Safety: Bucher Adds Load-Control Valves

By Michael Pyper for Bucher Hydraulics.

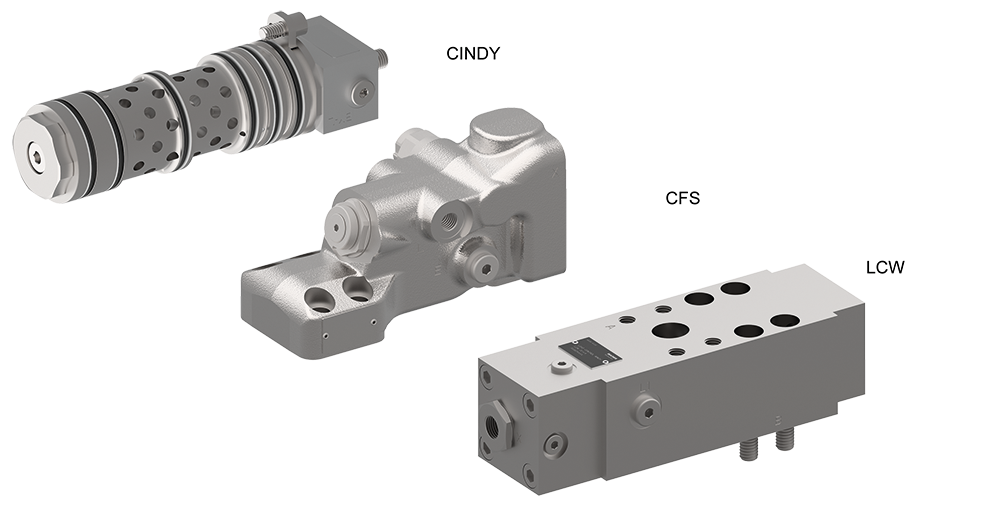

Bucher Hydraulics recently expanded its portfolio of safety valves with a new load-control valve for winches, as well as additional sizes of other load-control valves and pipe-rupture safety devices.

When enormous wind turbine rotor blades or entire building roofs have to be positioned with millimeter accuracy, valves from Bucher Hydraulics are usually used, especially for heavy loads. Bucher is expanding an already wide range of safety load-control valves. The CINDY follower principle, which has been tried and tested for decades, continues to play an important role.

Bucher manufacturers load-control valves, pipe-rupture valves, and now load-control valves for winches.

“We have expanded our range of load-control valves with a new version, the LCW – load-control valve for winches – developed specifically for winch applications,” René Müller, product manager – safety valves at Bucher Hydraulics, said in a press release.

Also new to the product portfolio: the compact flow control and safety valve, a size 25 pipe-rupture valve with a flat design.

Functional integration

“The pilot pressure bypass formerly needed a separate line. With the new LCW, we have succeeded in integrating it into the return line of the winch load-control valve,” Müller said, noting that the valve saves OEMs costs during installation because they have fewer components to install and the piping requirements are reduced.

In addition, the LCW is characterized by particularly sensitive and responsive starting behavior – important for positioning the heaviest loads with millimeter precision. Another aspect in times of rapidly rising energy costs is optimized efficiency, which is due to reduced throttling and pressure peaks during lifting and lowering.

Safety valves protect man and machine. Depending on the applicable standards, manufacturers use load-control valves or pipe-rupture safety devices. If heavy loads have to be precisely moved, held, and positioned, or if work access platforms have to hold their position and withstand great forces, Bucher’s safety valves are a good choice.

Müller noted that, with CINDY technology, the company has a long-proven concept for safety valves in a modular system. The valves offer a high opening ratio of 113:1, resulting in very small changes in pilot pressure for widely differing loads. Operators are happy that the joystick provides load-independent and responsive travel behavior. The low pilot pressure minimizes the energy required for lowering. For the end user, better energy efficiency saves operating costs.

“In addition, the bypass check valve, which is functionally integrated in a coaxial valve assembly, means a significantly smaller installation space for the valve,” Müller said.

Common safety valves close by means of spring force, which means it depends solely on the spring. Depending on the cylinder pressure, the spring applies considerable force, which is why this type of valve has an inherently lower level of safety.

“CINDY valves, on the other hand,” Müller said, “close due to the load pressure applied to the valve, which ensures maximum safety.”

CINDY valves can lift, hold, and lower. With SAE flange mounting, manifold mounting, and cartridge designs, three installation types are available. Valves with SAE flanges are available up to size 32 and allow a flow rate up to 1,200 lpm (317 gpm). The manifold-mounting version is available up to size 25 and has a maximum flow rate of 500 lpm (132 gpm). The cartridge design has a maximum size of 40, and it can be operated at a maximum flow rate of 1,300 lpm (343 gpm). The maximum operating pressure for all variants is 420 bar (6,091 psi), which represents a design safety factor of 3. In line with the modular system concept, these three installation types can be equipped with various operating and control options for a wide range of applications. In addition, the system can be adapted quickly and easily to meet customer-specific requirements.

Pipe-rupture protection

In the event of a burst pipe or hose, pipe-rupture safety devices prevent an uncontrolled lowering movement. The relevant standards (EN 474 and ISO 8643) require this type of valve for machines working under certain conditions. For example, excavator pipe-rupture valves are required whenever a lifting device such as a load hook is attached to the excavator bucket and more than one metric ton can be lifted.

“As a general principle, work machinery must be equipped with pipe-rupture safety devices on actuators in dangerous situations,” Müller said.

Taking the example of an excavator, the standards refer to boom cylinders as well as stick and adjusting cylinders. In the event of a burst pipe or hose, a vertical lowering speed of 150 mm (6 inches) per second at the bucket (the specification for burst tests) may at most double.

Speaking about the compact flow control and safety valve (CFS), Müller said, “Our CFS pipe-rupture valve for excavators goes well beyond this standard: it keeps the lowering speed virtually constant.”

Another important point: the falling speed of the load must not exceed 10 mm (0.04 inches) per second in the holding position.

“Because our excavator pipe-rupture valves are leak-free, we exceed this requirement,” Müller said.

The valve must be mounted directly on the cylinder – with no hose or pipe between. However, the gap between the excavator superstructure and the boom cylinder is often quite narrow in relation to the hose peripherals or the maximum deflection of the boom, and there is a risk of collision. The flat design of the CFS provides the decisive millimeters that save the need for any modifications to the excavator’s design when retrofitting this safety device.

The CFS valves also have an integral secondary pressure-relief valve to protect the actuators against overload. The actuator and inlet connections are standard SAE flanged ports, and the valves can therefore be retrofitted to existing machines without difficulty. Variations in load pressure – even to the maximum – have no effect on the fine-control characteristics and the hydraulic performance of the valve. In addition, the valve holds the actuator in its position when the main valve is centered.

The large opening ratio of 480:1 makes its mark with operators by delivering load-independent operation. The guaranteed closing force, even in the event of spring breakage, provides a high level of safety for man and machine if there is a malfunction.

Because the CFS pipe-rupture safety devices do not contain dynamic seals, the hysteresis is low, and the setting remains constant. Balanced load-lowering significantly reduces wear on the cylinder and ensures long service life as well as precise, finger-tip controllability.

The CFS pipe-rupture safety valves are available in the three sizes: 16 (SAE ¾” 6,000 psi-250 lpm), 20 (SAE 1″ 6,000 psi-350 lpm) and 25 (SAE 1¼” 6,000 psi-600 lpm).

In its standard design, the CFS weighs half as much as most comparable products on the market. Thanks to the zinc-nickel plating, all valves meet exacting requirements for corrosion protection in the excavator’s harsh working environment.