New Hybrid Concept for Actuating Subsea Valves

By Alexandre Orth, Head of Subsea Automation Systems, Bosch Rexroth, and Amadeu Placido Neto, Bosch Rexroth Test Engineer

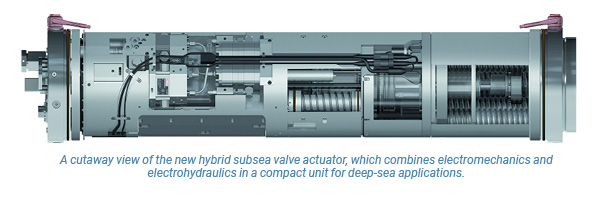

A new deep-sea actuator promises around-the-clock operation with little or no maintenance and no hazards

for people or the environment.

Bosch Rexroth’s subsea valve actuator (SVA) provides up to SIL3 safety, consumes up to 75% less energy and is designed for 25 years of operation. The SVA boasts an external pressure 300 bar and is compatible with a saltwater environment, 24-hour operation 365 days a year, and promises a 25-year lifetime with little or no maintenance.

Operational safety is especially important for underwater systems that produce oil and gas, to protect people and environments. Additionally, protecting the sea from the pollution that intentional leakage of hydraulic fluid causes is now also a key priority. The SVA uses the best of electromechanics and hydraulics in a compact unit for deep-sea applications.

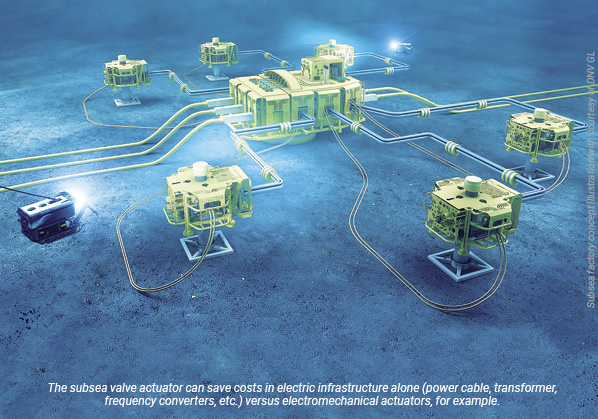

Multiple undersea wells may be controlled from a central location. Each well has its own control facility or plant. This type of system is known as a “subsea tree.” Each branch controls the production of its respective well via multiple process valves. The process valves are actuated by the SVAs, which in turn, receive their electrical control signals from the actuator control modules. When required, they must safely close the respective process valve in every operating state, even during power failure.

Self-contained axes with a hydrostatic drive

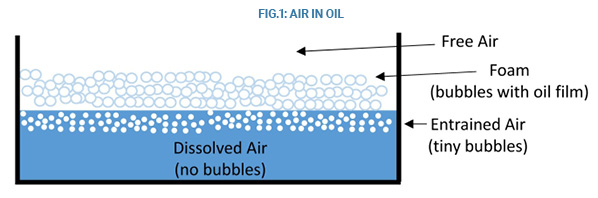

The SVA provides an energy-efficient and safe alternative to the previously used hydraulic or electromechanical actuators. SVAs are self-contained modules with their own closed fluid circuit. A variable-speed motor drives a robust hydraulic pump, which generates flow for the cylinder movements. Without an external power supply, a safety valve with a mechanical spring ensures that the cylinder also changes safely into the fail-safe position if the power fails. The cylinder, which opens and closes the well valve, can also be actuated externally by an underwater robot via an override. All key components of the drive train are installed redundantly. Altogether, SVAs provide safety on four levels with the redundant controls, the fail-safe spring and the intervention options from outside.

The benefits are especially clear when the solution is compared with the current state of technology. The vast majority of underwater actuators used around the world are still based on conventional hydraulics. This common structure has proven its durability and long-term safety over the past 50 years. However, operators still want to reduce the effort needed because conventional hydraulics require big, central hydraulic power units above water. These supply the actuators with fluid via lines, known as umbilicals, that can be kilometers long. At a working depth of 3,000 meters, several hundred liters of fluid accumulate in the lines alone. This is in addition to the demand for additional hydraulic accumulators and directional valves required for a complex subsea control module.

As the first alternative, equipment suppliers tried to set up electromechanical solutions. These only need to be supplied via power cables and connected to the actuator control modules via a data line. However, because they have no external mechanical intervention options for adjustments, electromechanical solutions have safety-related disadvantages. Due to their lower power density, they also require bigger housings and electrical batteries. The design results in high friction, causing mechanical wear on the power transmission and reducing the required 25-year operating period.

For these reasons, electromechanical solutions are at a critical disadvantage for subsea applications when a fail-safe emergency closure is needed.

Up to 75% less energy consumption

The SVA combines the benefits of both hydraulic and electromechanical solutions and eliminates the existing disadvantages. The decentralized fluid circuit means the topside hydraulic power unit, subsea hydraulic control module and kilometer-long umbilical cords are no longer required for the fluid. The SVAs only require a power supply and a data line, like the electromechanical actuators.

Hydraulic pumps generate the flow rate for the wear-resistant hydraulic gear. As a control principle, Rexroth uses a displacement system here, which regulates the flow rate with low friction from out of the rotation speed. This simplifies the design because proportional valves are not required and significantly increases energy efficiency. Compared with the purely electromechanical actuators, SVAs consume up to 75% less power at peak performance.

Considering all the actuators used to operate a subsea field properly, the SVA can provide a huge cost saver for the electric infrastructure, such as power cables, transformers, and frequency converters. The motors can be configured considerably smaller with the same adjustment force of the actuators, which in turn saves installation space and costs.

Considering all the actuators used to operate a subsea field properly, the SVA can provide a huge cost saver for the electric infrastructure, such as power cables, transformers, and frequency converters. The motors can be configured considerably smaller with the same adjustment force of the actuators, which in turn saves installation space and costs.

As part of its condition monitoring capabilities, built-in sensor technology continuously records the operating states within the actuator and reports them to the higher-level master controller. Trends can then be analyzed, allowing deviations to be identified and solved early.

Self-contained industrial axes as a standard

Within the SVA, there are 2 bar of overpressure at every depth because of the redundant pressure compensation system. This prevents the penetration of saltwater and the need for large housings with a pressure-neutral design. Rexroth only uses underwater cables, even within the axis. All electrical components are also encapsulated. Rexroth’s deep-sea specialists used the principle of self-contained axes for industrial applications when developing the SVA.

Where required, Bosch Rexroth has made modifications to the components for deep-sea use at depths up to 6,000 meters. The system and core components also meet the special requirements of different classification societies for marine, offshore and subsea use.

Working closely with leading equipment suppliers and operators, the SVA developers used the latest simulation technology for the “proof of concept” and built prototypes for field trials. This innovative drive technology combines the best of electromechanics and hydraulics to help ensure safe and reliable conveyance technology on the seafloor, making the vision of an “all subsea factory” a reality sooner.

For more information, visit www.boschrexroth-us.com.