Pneumatic Automation Solves A Difficult Production Issue in the Poultry Industry

The Ace Specialties chicken breast deboner mimics hand trimming for low waste and high output

by Steve Sterling.

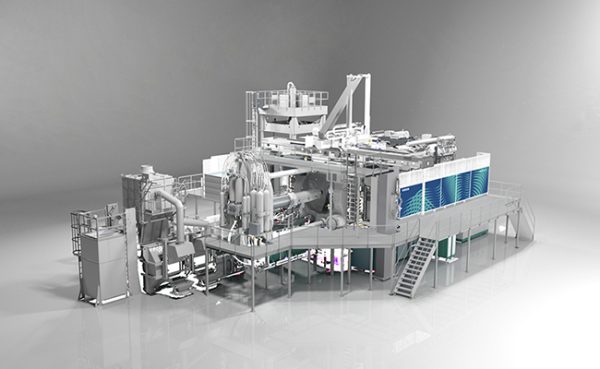

The CMS ACE DB-5 deboner is a 22-foot-long machine that automatically processes 50 birds per minute. Even at 22 feet, the DB-5 is a small footprint machine as compared to other solutions.

Among all the choices U.S. shoppers have in their supermarket’s meat department, they most often purchase chicken. Consumer retail spending on chicken tops $15 billion and the highest-selling part of the chicken is breast meat, which accounts for 57% of retail sales. Boneless breasts are in high demand for taste, recipe versatility, and ease of preparation – no bones to remove.

The problem for the low-margin poultry industry is that deboning a chicken breast is labor and time-intensive in an era where labor is in tight supply and wages are rising. ACE Specialties, Russellville, Arkansas, developed a deboning machine that comes as close to low-waste hand deboning as any automated solution to date. The CMS Ace DB-5 Breast Deboner relies nearly 100% on pneumatic automation. Sales are strong for the DB-5. Poultry processing managers have found the cost of ownership and maintenance of the DB-5 is significantly lower than other automated breast deboning solutions.

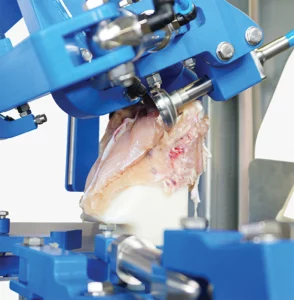

A closeup image of the final three processing stations clearly shows multiple pneumatic cylinders being applied to automate cutters and plows.

“It’s the best automated deboning machine in the business,” said Andy Harris, Vice President of Operations, at Harrison Poultry. “Yield, quality, uptime, and footprint all make it appealing, and automation is where we are heading. The quality of the product is very good, and the yield is comparable to hand deboning.”

Origins

In 2016, Jeremy Estes had nearly 20 years of experience in original equipment manufacturing of poultry equipment. Estes became restless when the company he worked for sold, and he felt he had gone as far as he could under the new leadership.

As the bird enters the machine, a cylinder-based press pushes the body down to its lowest anchor point on the cone.

Jeremy’s father, Andrew, who had also been in the poultry equipment manufacturing business, found retirement in his words “boring.” Father and son cast around for a project – something they could turn into their own business and feel energized again. Both knew that a high-output/low-waste automated chicken breast deboning machine would solve a major production issue. The Estes decided to develop an automated breast meat deboner. It took them nearly five years to succeed.

The CMS ACE DB-5 Breast Deboner

The CMS ACE DB-5 deboner is a 22-foot-long machine that automatically processes 50 birds per minute. Even at 22 feet, the DB-5 is a small-footprint machine as compared to the competition. The DB-5 outputs wings, boneless breasts with rib meat attached, and clipped tenders. (Tenders or chicken tenderloins are strips of meat attached to the underside of each breast. Tenders taste and look the same as chicken breast.). Except for the servo-controlled conveyor, the rest of the DB-5’s automation is based on pneumatics.

The Wishbone & Rib Plow drives a blade at a slight angle down to the body of the bird with significant force and separates the breast meat from the wishbone.

“Pneumatics is the only way of having so many fast and simultaneous mechanical actions in such a compact space,” said Jeremy Estes, President, of Ace Specialties. “Designing this machine any other way would have required too much space and be cost-prohibitive.

Sanitary design

Pneumatics not only had to carry the bulk of the automation, but the compressed air system and components also had to meet sanitary design guidelines. “It was vital that an automated solution meet the highest standards of food-safe operation,” Estes said. “We worked with Motion Industries, Russellville, Arkansas, our distributor, to identify pneumatic components that would enable us to meet Food Safety Modernization Act guidelines for reducing potential sources of biologic, allergen, and particle adulteration. We standardized on Festo pneumatic automation and our Festo Sales Engineer, Steve Jackson, provided additional technical support.”

One of the first design goals had to be ensuring that compressed air, which is contaminated with solid particles, oil, and water, be filtered to the highest level. Cleaner compressed air would also prolong the life of components. Organizations such as the British Compressed Air Society (BCAS), 3A Sanitary Standards, VDMA Mechanical Engineering Industry, and Safe Quality Food (SQF) have published recommendations for specific air quality requirements. SQF recommends a final filtration stage of 0.01 microns with a filtration efficiency of 99.999% to be located at the point of use for direct food contact.

Tenders or chicken tenderloins are strips of meat attached to the underside of each breast. At this station tenders are clipped and harvested.

Motion Industries recommended a Festo MS-6 series air preparation system with MS6-SV safety valve with a button to manually shut off and vent air when needed. This air preparation unit met SQF guidelines. Festo recommends that air coming from the compressor also needed to be at a certain level, otherwise, the air preparation unit would be off. In this case, the air into the MS-6 should be 7:4:4; the outflow from the machine should be 1:4:2.

The next clean design components selected were QS fittings and PUN-H tubing. The QS fittings have parallel threads that allow the fittings to sit flush with the cylinder. Sitting flush is essential for sanitary operation as no threads are exposed. Exposed threads trap contaminants. PUN-H tubing is resistant to cleaning agents, microbes, and wear from hydrolysis and is FDA-compliant. Without wear resistance, tubing can develop crevasses that trap contaminants.

For sanitary operation, machine parts must be resistant to corrosion and be mechanically and chemically stable. The Estes standardized on the Festo CRDSNU pneumatic cylinder, which is made with corrosion-resistant stainless steel. The CRDSNU’s design rigorously conforms to Current Good Manufacturing Practices (cGMP) criteria. For example, there are no threads in the bearing cap and thus a reduced possibility of trapping contaminants. Its self-adjusting end-position cushioning system is designed without contaminant-susceptible adjusting screws. The cylinder was specified with NSF-H1 food-safe grease and FDA-approved seals. The CRDSNU has a long service life thanks to an optional dry-running seal. Important for the DB-5, these cylinders offer a wide range of variants because of the multiple sizes required within the machine.

A chicken wing showing a clean cut.

Operation

The DB-5 processes the front half of the chicken – the body where the legs have been removed earlier at the processing facility. With the machine operating at 50 chickens per minute, it requires two employees to load the DB-5. The employees place each chicken on a patented cone attached to the machine’s conveyor. Servo drives and motors control conveyor motion. The cone securely holds the bird as it travels stage by stage. As the bird enters the machine, a cylinder-based press pushes the body down to its lowest anchor point on the cone. The machine records the height of the bird following the downward press. This measurement is critical later in the process.

There are eight processing stages, including the downward and shoulder press in the DB-5. These include:

- Downward and Shoulder Press

- Neck Skin Cutter

- Wing Cutter

- Scapula Cutter & Skin Wiper

- Wishbone Cutter

- Wishbone & Rib Plow

- Breast Roller

- Tender Harvester

Clipped tenders.

At each of these stages, multiple pneumatic cylinders move cutters and plows. Typically, pneumatic cylinders operate singly for simple in and back motion. In the DB-5, multiple cylinders carry out an intricate series of interlocking motions. The cylinders drive cutters, plows, and hinged mechanical components that open and close or extend and retract as the cylinders advance and retreat.

For example, at Stage 6 the Wishbone & Rib Plow drives a blade at a slight angle down to the body of the bird with significant force and separates the breast meat from the wishbone. Then a cylinder extends, pressing a hinged right and left plow to the sides of the carcass. The plows drive forward, running between the rib cage and the breast meat, effectively separating the meat from the bones. At Stage 7, the Breast Roller, a roller is adjusted to the position measured as that bird entered the DB-5 and, with force, rolls the deboned breast meat from the carcass and onto a conveyor to exit the machine.

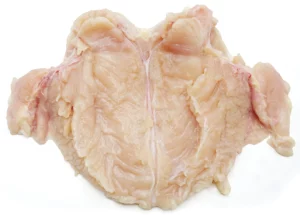

Rib meat, left and right, are intact. There is no cartilage remaining on the boneless breast. ACE DB-5 produces butterfly cuts, as shown here, clipped tenders, and whole wings with minimal need for rework.

The Estes designed cutters, plows, and other components to glide along the body of the bird. Using the contour of the carcass as the cutting and plowing guide was one of the design innovations that closely mimics deboning by hand.

A second design innovation involves servo control of the conveyor. The conveyor rapidly accelerates and decelerates between each stage. This speed is essential to process 50 birds per minute. Servo control is vital to the accuracy of the process as the conveyor stops at the precise processing point of each stage.

Machine mounting of the DB-5’s control panel contributes to its small footprint. In the cabinet are a PLC, servo drives, other assorted electronics, and an ultra-compact Festo VTUG valve terminal. The VTUG can house 48 valves in the same space normally required by 24. Compactness enabled higher functionality to be packed into the control panel. The VTUG features bottom or side porting of tubing. This means there is no pneumatic tubing within the cabinet, creating a cleaner and less cluttered installation. The PLC communicates with the valve terminal via IO-Link.

Sales and marketing

The Estes are the first to say they are engineers and machine builders rather than sales and marketing experts. Once they verified through a pilot installation that the DB-5 performed to expectations, they looked for a sales and marketing partner. They found that partner in CMS (Cantrell Mechanical Solutions, Inc.), Gainesville, Georgia. CMS delivers food and other processing solutions to the poultry, turkey, pork, beef, vegetable, fruit, nuts/legumes, fish, and pet food industries. CMS handles all sales, marketing, and field support for the DB-5.

What’s next for Ace Specialties and the DB-5? Father and son continue to refine the design of the DB-5. They attempt to make every improvement to be backward and forward-compatible for machines in the field and machines being built. And the next innovation? The poultry industry will have to wait and see.