Pneumatic Cylinder ISO Standards

Let’s start with a little background on the ISO committees. ISO TC131 is the committee responsible for fluid power. One of the groups underneath TC131 is subcommittee 3 (SC3), which is responsible for cylinder standards. Underneath this are the working groups that put together the standards for cylinders. Currently there are three active working groups: WG2 for pneumatic cylinders, WG3 for hydraulic cylinders, and the recently re-established WG4 to work on ISO 6099. This is because it impacts both the pneumatic and hydraulic standards, needing members from both working groups to participate.

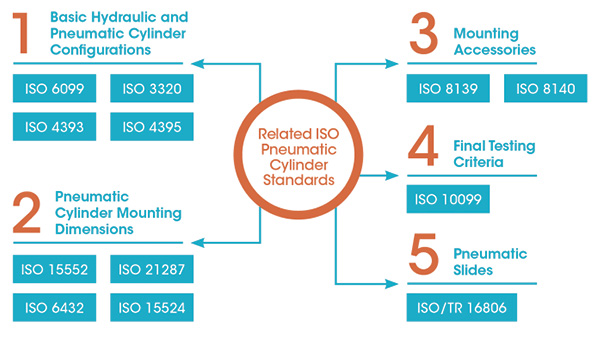

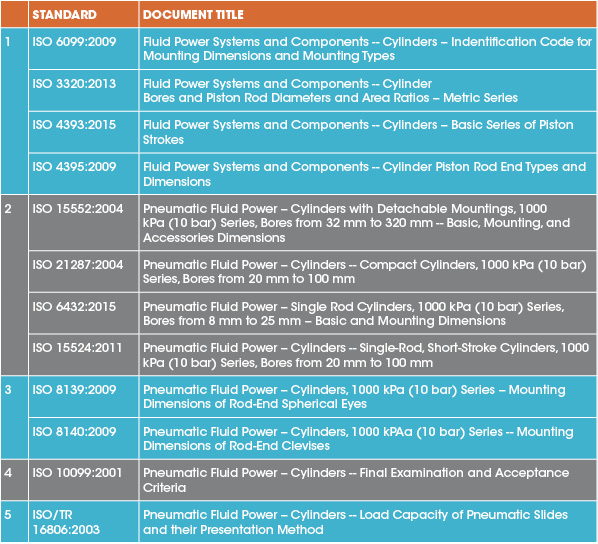

Now back to pneumatic cylinder standards. The table below lists standards that WG2 would be responsible for and would provide feedback as part of SC3 work. There are other standards that have impact, but responsibilities are in groups outside of SC3. One example would be the reliability standard ISO 19973. Part 3 of this standard is for pneumatic cylinders.

The first group of standards are common to both pneumatic and hydraulic cylinders. These set the ground work for the next group of standards by harmonizing dimensional call-outs, as well as creating common piston rod and bore sizes. The second group of standards are the “meat and potatoes” portion. These are the dimensional standards that most people think about when they are working to select a cylinder for a specific application. The third group is the rod-end mounting accessories. The fourth group is the final testing criteria. This provides a good baseline for manufacturers to use and gives the end customer an understanding of the testing completed on the product before it ships. The last item is a technical report that describes a method for calculating the load capacity for specific types of guided cylinders.

Most people are interested in the standards in group 2, so I will discuss these in more detail.

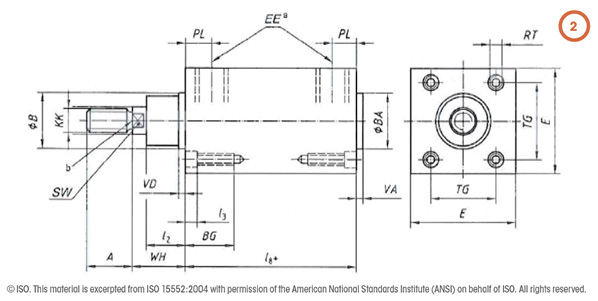

ISO 15552: Pneumatic Fluid Power – Cylinders with Detachable Mountings, 1000 kPa (10 bar) Series, Bores from 32 mm to 320 mm – Basic, Mounting, and Accessories Dimensions

This is probably the most well-known standard. This tie-rod cylinder standard evolved from the German VDMA 24562 standard, then to ISO 6431, and now ISO 15552. (See excerpt in Fig. 2.)

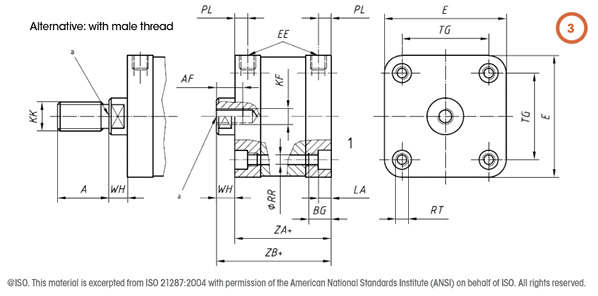

ISO 21287: Pneumatic Fluid Power – Cylinders – Compact Cylinders, 1000 kPa (10 bar) Series, Bores from 20 mm to 100 mm

With the beginning of a push for more compact cylinders, this was the first cylinder standard created to accommodate this growing theme. At the time work was starting, there was no one who manufactured this specific cylinder. One of the ideas behind this design was to keep the mounting bolt pattern the same as ISO 15552 so that mounting hardware could possibly be used. (See excerpt in Fig. 3.)

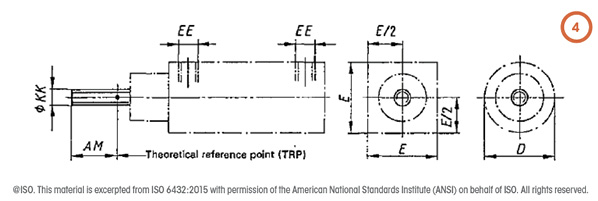

ISO 6432: Pneumatic Fluid Power – Single-Rod Cylinders, 1000 kPa (10 bar) Series, Bores from 8 mm to 25 mm – Basic and Mounting Dimensions

This is the smaller bore standard that has been in existence for quite a while. Most of the manufacturers use a crimped stainless steel tube design to connect the end caps. (See excerpt in Fig. 4.)

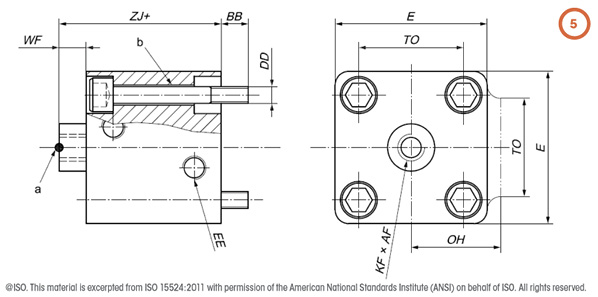

ISO 15524: Pneumatic Fluid Power – Cylinders – Single-Rod Short-Stroke Cylinders, 1000 kPa (10 bar) Series, Bores from 20 mm to 100 mm

This standard is even more compact than ISO 21287. This cylinder was very popular in the Asian market even before it became a standard, and its acceptance has grown throughout the rest of the world. With this standard, the mounting hardware for ISO 15552 is not compatible with this standard. (See excerpt in Fig. 5.)

I hope this provides you with a better understanding of the ISO standards for pneumatic cylinders. But you may ask, what about the NFPA standards? The existing standards are still active and product continues to be manufactured. As discussed in previous articles, the charter for NFPA is changing. In general, it will not actively create new national standards, but would submit these to ISO for work to be done at that level. NFPA will continue to do periodic reviews of the standards. During the review, it will be decided to reaffirm, withdraw, and/or submit the standard to ISO to see if this could become an ISO standard. My expectation is that if cylinders continue to be manufactured and sold that are in conformance to the NFPA standards, then the standards will continue to be reaffirmed by NFPA. But, it is doubtful that they will become ISO standards for the simple reason that they are classical designs, even though they are well suited for heavy-duty and rugged applications.

ISO RESOURCES

The NFPA Standards Locator: www.npfa.com/standardization/findstandard.aspx

Why Standardize? www.npfa.com/standardization/whystandardize.aspx

Interested in Joining a TAG Committee?

www.npfa.com/standardization/standardscommittee.aspx

Contact Denise Rockhill at drockhill@nfpa.com. Learn more about NFPA and ISO standards at www.nfpa.com/standards.