Polyurethane O-Rings Stand the Test of Time

Elements of this image furnished by Adobe Stock; Contributor: Liudmila

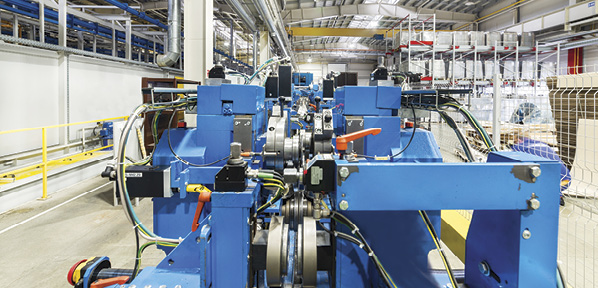

Hydraulic cylinder fitted with Hallite 003 Polyurethane O-Rings. Image courtesy of Hallite Seals

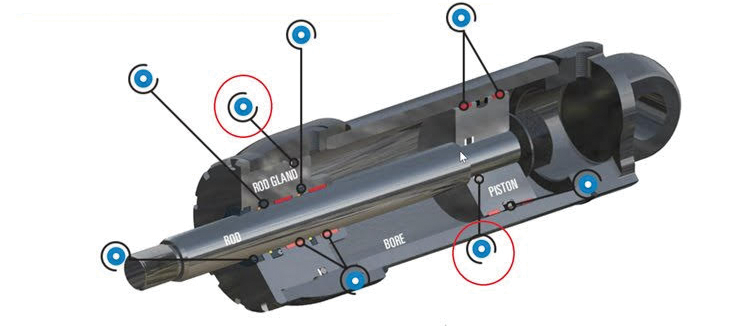

Several new material options, innovations, and emerging technologies have led the fluid power industry, primarily OEMs and cylinder builders, to look closely at polyurethane (PU) O-rings. These common, trusted seals renowned for their durability, resilience, and adaptability have earned their rightful place in hydraulics. Static seals, like PU O-rings, are pivotal in preventing leakage between connecting components in fluid power systems, notably between connecting rods and piston heads, cylinder tubes, and glands. Often considered secondary to dynamic seals, they are instrumental in maintaining pressure where it matters most.

In today’s multifaceted fluid power industry, grasping the intricacies of the PU O-Ring, especially in medium and heavy-duty technical applications, is far from straightforward. This understanding necessitates advanced manufacturing knowledge, technological expertise, and proven processes for managing the diverse range of material options available. The dynamic nature of fluid power systems demands seals that can perform reliably under varying pressures, temperatures, and operational conditions.

Given these complexities, it is essential to delve deeper into the specific attributes and advantages of PU O-Rings within hydraulic fluid power cylinder applications. We will explore how these seals offer enhanced performance, longevity, and reliability compared to traditional sealing solutions. Additionally, we will examine the manufacturing processes and material characteristics that enable PU O-Rings to meet the rigorous demands of modern hydraulic systems.

By reviewing these aspects, we aim to provide a fresh perspective on the application of PU O-Rings. This exploration will not only underscore the technical benefits of PU O-Rings but also emphasize their role in advancing the efficiency and durability of hydraulic systems across various industries.

The PU O-Ring is a singular solution that can standardize a cylinder configuration traditionally addressed with different components. It can perform across all duty cycles and a wide range of pressure requirements. The cylinder builder can rely on the PU O-Ring to achieve performance levels of up to 50 MPa (7250 psi) in a singular solution, simplifying the design process. Here are five key advantages of using PU O-Rings in hydraulic cylinder applications:

Simplified Design

The PU O-Ring replaces the traditional two-piece elastomer O-ring and backup combination, offering a singular, streamlined solution.

This simplification leads to a more straightforward assembly process.

Reduced Assembly Errors

As a single-component solution, the PU O-Ring minimizes the risk of assembly errors that can occur with multi-piece configurations.

Ensuring a more reliable and consistent seal performance.

Lower Inventory and

Handling Costs

Fewer components mean reduced costs related to purchasing and stock handling.

Inventory management becomes simpler and more cost-effective.

Compact Solution

The PU O-Ring’s compact design is ideal for static applications where space for a seal in the cylinder is limited.

This compactness does not compromise its sealing efficiency, making it versatile for various applications.

Versatility in Materials

PU O-Rings are available in a wide range of materials, catering to both low- and high-pressure sealing applications.

This versatility ensures that the right material can be chosen based on the specific requirements of the hydraulic system.

Once the design characteristics of PU O-Rings are considered, selecting the appropriate materials for specific applications should not be overlooked. Ensuring the material choice matches the operating conditions is crucial for optimal performance and longevity of the seals.

Hallite polyurethane O-Rings in Hythane

high-performance materials. Image courtesy of Hallite Seals.

Materials matter

High-performance materials provide desirable assurances, such as easy installation, reliability, and durability. For example, high strength TPU allows the PU O-Ring to withstand high pressure and shock loads.

When it comes to materials, there are many options, including the Hythane range, which offers resilience and extrusion resistance and eliminates the need for additional anti-extrusion backup rings. Hythane 591 high-performance polyurethane supports high-pressure sealing, and Hythane 181 is an alternative material option for more demanding low-temperature conditions. Whatever material option you choose should be suited for the application.

Here’s a common situation. An engineer uses a standard O-Ring up to 16 MPa (2320 psi) in NBR 70 in an application. To address the need for a higher pressure in the application, an O-Ring in NBR 90 is added, as an option. However, as the pressure increases further, a backup ring must be added, culminating in three components/options. For every application involving pressure, the engineer must stop and consider a long list of configurations to achieve the desired solution. Since the PU O-Ring as a standard is configured to the highest pressure performance, there is no need for the cumbersome evaluation of pressure and materials for every application. This makes it a safer solution for engineers who are designing the cylinders, and it saves time.

Equally important is the fact that the PU O-Ring is a single component that saves space in the assembly and storage. Imagine installing hundreds of sizes of O-rings, each requiring an evaluation of configurations and options. We can quickly calculate the number of parts to see how this can become an issue.

Endless potential

As we’ve explored, PU O-Rings have established themselves as an excellent choice for hydraulic cylinder applications. However, their advantages extend beyond this singular use. Various other elements within hydraulic circuits or systems, such as hoses, fittings, and valves, can also benefit from the innovative qualities of PU O-Rings.

The fluid power industry recognizes the challenges associated with fitting valves with O-Rings due to the compact sealing requirements, especially for control and solenoid valves. This is where PU O-Rings demonstrate significant superiority over standard O-Rings, which often require multiple components. PU O-Rings streamline the sealing process, providing a simplified, yet highly effective solution.

The potential applications for PU O-Rings are vast and continuously evolving. Seal manufacturers, in collaboration with industry leaders, are pushing the boundaries to explore new and innovative sealing solutions. This includes applications in emerging sectors such as hydrogen and biofuels, where the demand for reliable and compact seals is paramount.

By leveraging the unique properties of PU O-Rings, the fluid power industry is poised to overcome traditional challenges, opening the door to new possibilities and advancements in hydraulic system design.