Regenerative Circuit Drops Out

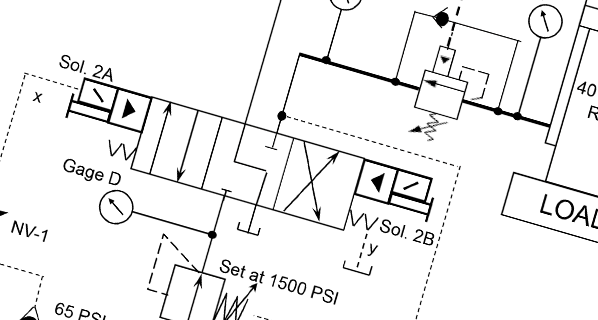

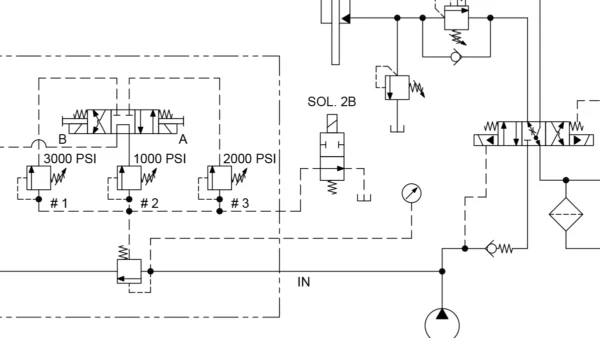

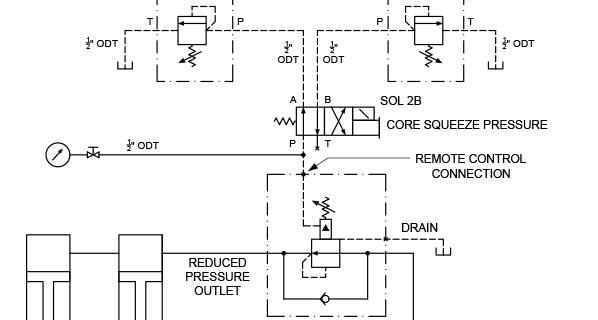

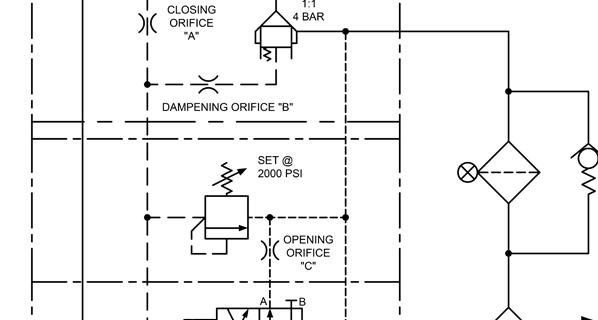

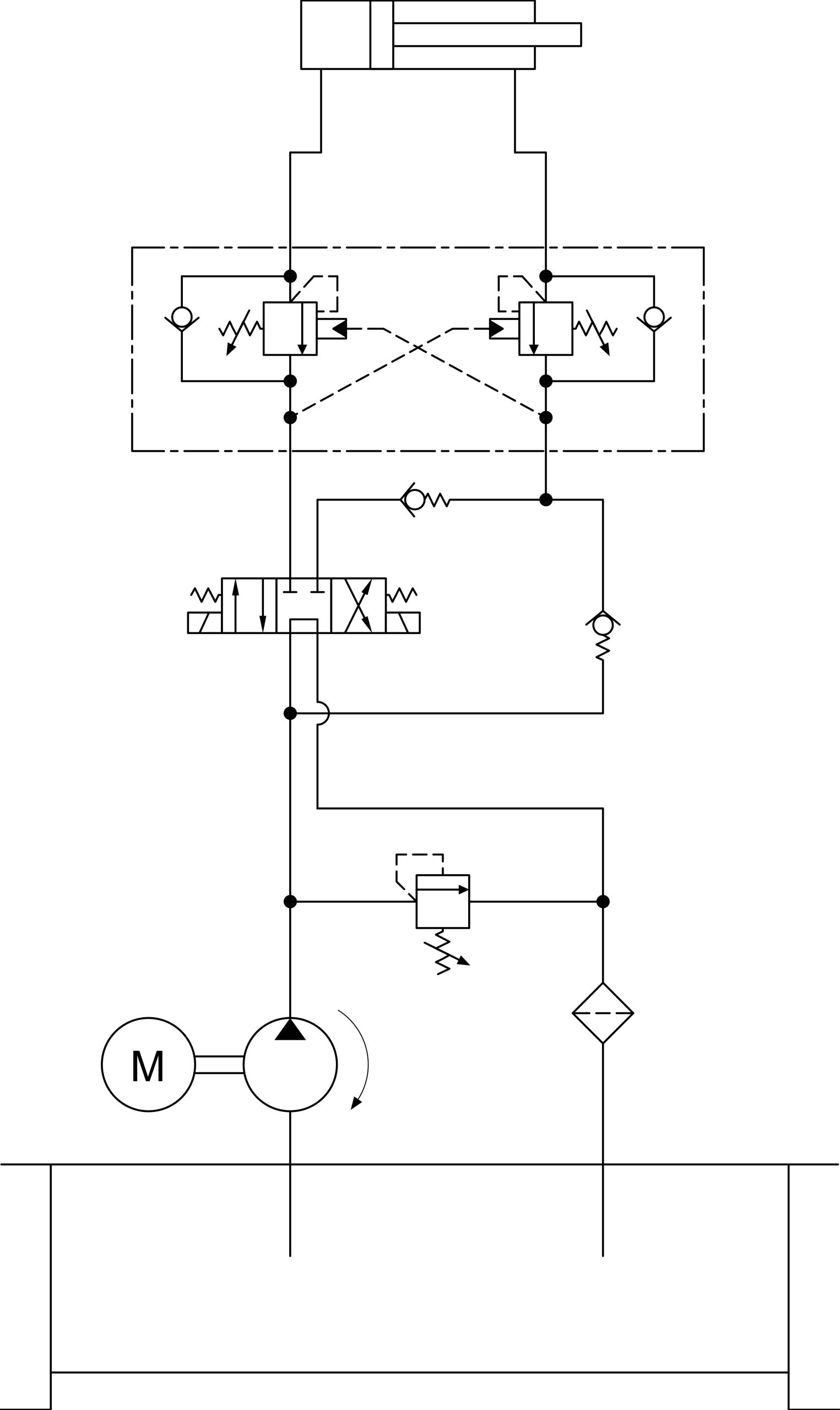

A specialty machine builder was having problems getting a vertical cylinder with a regenerative circuit to lift a hinged member. When the hinged member was lowered, an attached drill would drill a hole and lift it out of the way so the work piece could move horizontally and then have another hole drilled. It looked somewhat like a band saw that would cut horizontally fed bars and angles.

When the cylinder was extended to lift the pivoting fixture up, it would extend about halfway up slowly and then pick up speed reaching the designed regen speed. You could hear oil blowing over the relief valve when it was extending slowly and stop when the regen speed was reached. Adjusting the counterbalance valves did not help.

What was the problem?

See the Solution

CFC Industrial Training

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com.