Figure It Out: Press Upgrade Didn’t Fix Overheating Problem

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

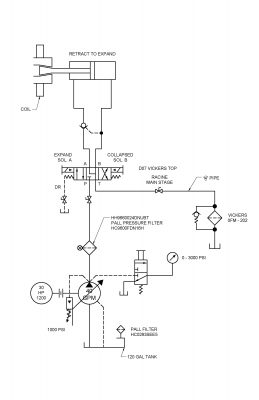

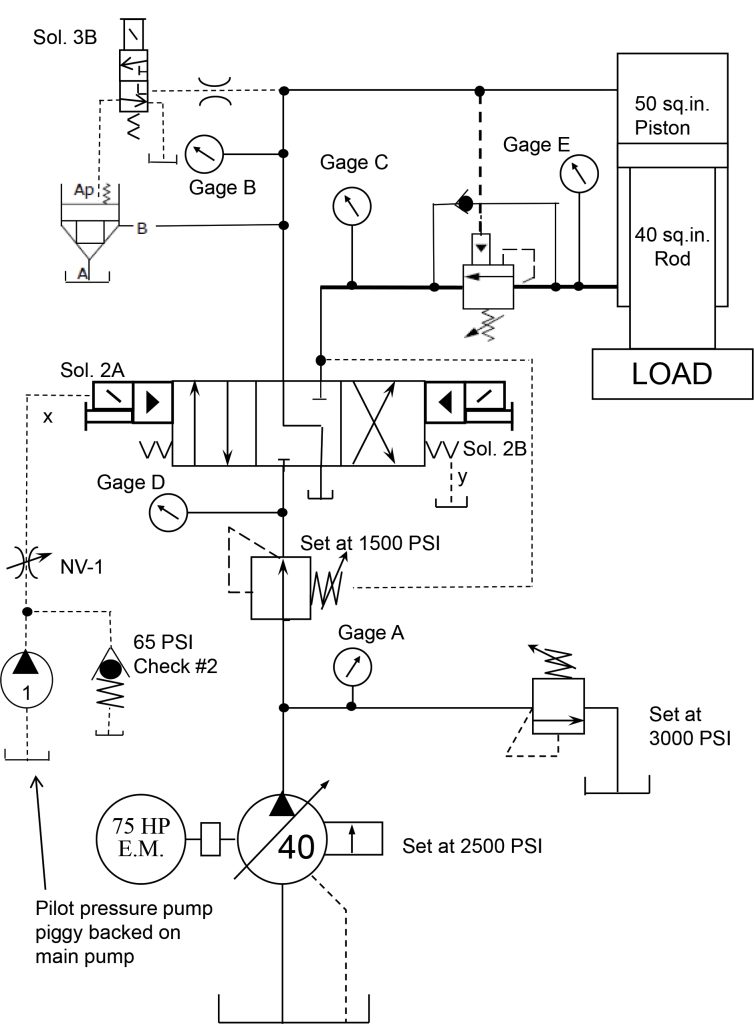

The above circuit drawing for a hydraulic press was upgraded after 10 years of continuous 24/7 operation. They replaced the main directional valve, added valve 3B unloading circuit, and installed a separate pilot pressure pump. This was all done to reduce the heat that was thought to be caused by the high flow through the directional valve when the cylinder retracted and omitted a 75 psi (0.5 MPa) back pressure check in the main pump line that supplied external pilot pressure to the valve.

The press was operational, but it still had the overheating problem that the upgrade was supposed to fix. They did find that the pilot line circuit was extremely hot going to the directional valve, and the line from check valve #2 to the tank was even hotter. The case drain line from the main pump to tank was warm like the original design.

What could be the problem?

See the Solution

The upgrade to the 60-ton press heating problem was due to the absence of a solid pilot pressure plug inside the valve, allowing the main pump pressure to force oil backward through the pilot pressure line and over the small 65 psi (0.44 MPa) check. Installing the solid plug solved the problem.

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com. Visit fluidpowerjournal.com/figure-it-out to view previous problems.