Research to Watch: AC Hydraulic Pump/Motor

This column will bring you the progress of the pre-competitive research being conducted at member universities that are part of the CCEFP network. This research will help give insight into the future direction of fluid power.

The Center for Compact and Efficient Fluid Power (CCEFP) holds a monthly forum, highlighting research, workforce, and special topic presentations.

CCEFP is a network of fluid-power-research laboratories, academic faculty, graduate and undergraduate students at nine universities. It is also a National Science Foundation Research Center. For more information on CCEFP, visit www.ccefp.org.

Since 2014, the National Fluid Power Association (NFPA) Foundation has supported and is helping to expand the pre-competitive fluid-power-research activities of the CCEFP, dramatically increasing the number of institutions and students impacted by its research program. For more on NFPA, visit www.nfpa.com/aboutnfpa/missionfocus.aspx.

Project Leaders: James Van de Ven, Associate Professor of Mechanical Engineering (UMN), Eric Barth, Associate Professor of Mechanical Engineering (Vanderbilt), and Kim Stelson, Professor of Mechanical Engineering (UMN)

Institutions: University of Minnesota and Vanderbilt University

PURPOSE

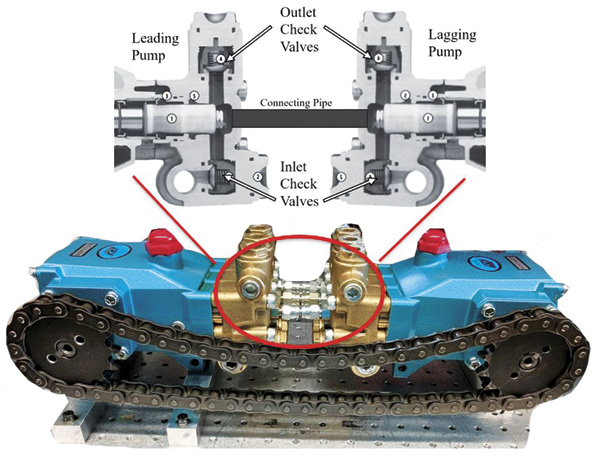

A high percentage of electrical systems are AC, but virtually no hydraulic AC systems are available. This project will model, design, prototype, and experimentally characterize a novel pump based on AC hydraulics for the application of displacement control. The AC pump is formed by joining

piston pairs from two fixed displacement pumps. By changing the phase angle between the two pumps, the displacement of the pump is varied.

The majority of existing hydraulic circuits use metering valves to control the load. Such valves that throttle the flow fundamentally dissipate power as a means of controlling delivered power. A more efficient alternative is to utilize a variable displacement pump to control each actuator, termed displacement control. Critical to displacement control is the performance and efficiency of the variable displacement pump across a wide range of displacements and pressures. For multi-actuator circuits where multiple pumps are driven on a common shaft, the package size and weight of the pump are also important.

PROGRESS

The model was used to capture piston kinematics and cylinder pressure as functions of the pump’s phase shift angle. The model also captured flows between pairs of cylinders as functions of the pump’s phase shift angle. The model captured check valve dynamics and input motor torque. Leakage, viscous friction, and effective bulk modulus were considered.

The simulation followed the results of the experiment well. However, results started to deviate from the model at higher-phase shifts, probably due to the large dead volume. In addition to the large dead volume, the prototype was also limited by the fact that there was no active control of the pump displacement.

NEXT STEPS

Bosch Rexroth donated a radial piston pump, and the researchers will modify the pump for active phase angle control using a cam phaser.