Rotating Stage’s Hydraulic Motor Keeps Leaking

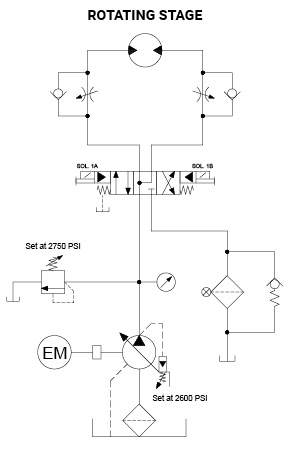

A large entertainment stage is rotated by a Geroler type hydraulic motor shown on the circuit. The regenerative center position on the directional valve eliminated a sudden jerk when first started since both ports were already pressurized. The pilot operated directional valve also had a smaller pilot pressure orifice installed to slow down the shifting speed softening the acceleration phase of the start cycle.

A large entertainment stage is rotated by a Geroler type hydraulic motor shown on the circuit. The regenerative center position on the directional valve eliminated a sudden jerk when first started since both ports were already pressurized. The pilot operated directional valve also had a smaller pilot pressure orifice installed to slow down the shifting speed softening the acceleration phase of the start cycle.

The problem they were complaining about was the big puddle of oil leaking out from under the stage every couple of months that required replacing the hydraulic motors that were leaking out through the shaft seal. They changed to a different Geroler brand motor and still suffered the same failure.

The oil is leaking out of the geroler motor shaft seal when the pump is turned on and the directional control valve is in it’s neutral position. Both ports of the motor are pressurized to the pump compensator setting of 2600 psi, which is much too great for the shaft seal hence the leakage. Typically a geroler type motor would have a case drain port which should be plumbed back to tank (low restriction) in a bi-directional application such as this, which would solve the shaft seal leakage.

Excessive blow by causes excessive pressure in the housing, blowing out shaft seal.