New Safety Brake for Small Wind Turbines

A new safety brake developed by Suco Technologies can reliably protect small wind turbines against storm damages due to excessively high wind speeds.

Small wind turbines are designed mostly for low and medium wind speeds. The dangerous wind speeds from storms and hurricanes can damage, or even destroy, the rotor. To protect the rotor from damage, rotor speeds are monitored and decreased when wind speeds surpass the turbine’s limits. Only when wind speeds have decreased will the rotor brake be released. The monitoring normally requires complex and costly mechanics. When using electronic systems, a permanent supply from an external power source is required.

Small wind turbines are designed mostly for low and medium wind speeds. The dangerous wind speeds from storms and hurricanes can damage, or even destroy, the rotor. To protect the rotor from damage, rotor speeds are monitored and decreased when wind speeds surpass the turbine’s limits. Only when wind speeds have decreased will the rotor brake be released. The monitoring normally requires complex and costly mechanics. When using electronic systems, a permanent supply from an external power source is required.

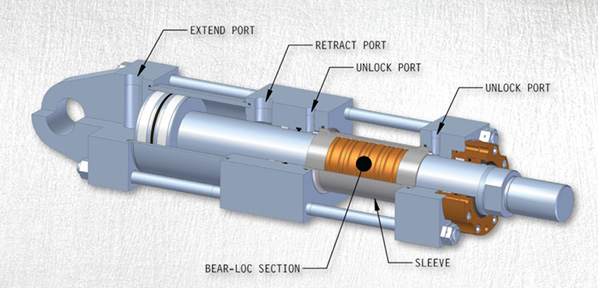

With the advanced development of a conventional centrifugal brake, Suco Technologies has chosen a solution using a proprietary, patent-pending technology. Even though the standard centrifugal brake activates at certain rotational speed to avoid exceeding critical limits, it still does not make it possible to brake down to a standstill. This limitation was identified when developing this new safety brake.

Based on the principle of a centrifugal brake, a purely mechanical, dependable brake was developed that, in the case of a severe storm, enabled the rotor to safely come to a standstill without any need for an external power supply. The automatic restart for the rotor, i.e., the release of the rotor brake, is fully automated and secured by a thermal element. Thus, manual unlocking of the brake is unnecessary. This safety brake can be adapted to most designs of small wind turbines.

The new safety brakes are used for small wind turbines, providing a self-sufficient power supply to buildings and other structures whose existing infrastructure is not connected to the power grid. Finally, the new safety brake offers the highest degree of safety and dependability, even when confronted with the most formidable weather event.