Shop Compressors: One or Two Units?

By Ron Marshall, Marshall Compressed Air Consulting

When purchasing shop compressors, do you buy one unit or two to make an energy efficient choice? The answer depends on the type of compressor chosen.

Reciprocating Compressors

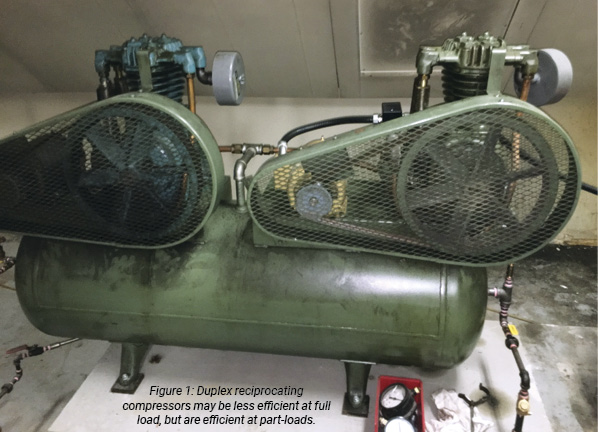

The traditional compressor type for small shops is the piston-style compressor. These units are great for automotive shops with very light loads with occasional peaks when large tools are used, but they have their drawbacks. Reciprocating compressors are noisy and usually run hot. In fact, this compressor type is typically not rated for continuous duty. This is because the cooling system is very simple, typically just a fan designed into the drive pulley, and a copper pipe with fins to cool the air. If these compressors are heavily loaded for extended periods they will overheat, damaging the compressor internals and reducing the compressor capacity.

A second compressor can be added, like the tandem unit in the accompanying photograph, but the two compressors must be carefully controlled so as not to allow one of the compressors to run continuously and burn out.

This type of compressor is not very efficient at full load, but the design makes up for this failing in being very good at handling low loads. So this inexpensive-to-maintain compressor style would be a good choice for shops with low loads. One compressor or two would not make a difference in efficiency.

Screw Compressors

Many shops choose screw compressors when they modernize their systems. These devices are quiet, run at any duty cycle, and can run at full load throughout the whole life of the unit if required. The cooling systems of these units are usually more complex and result in the compressors discharging compressed air at slightly above ambient temperatures, making it easier to dry the compressed air output, better eliminating moisture from the airstream.

But the common fixed-speed type of screw compressor has a few disadvantages compared to reciprocating style. The maintenance costs are often much higher since the units are more complex and use specialty lubricants and filters. Also if installed with a normal-size storage receiver capacity, this compressor type can continue to run unloaded, wasting power, even when producing no compressed air. This can be a problem if one large compressor is purchased instead of two smaller ones.

A typical screw compressor consumes about 35% of its full load power when unloaded, whereas a reciprocating compressor consumes no power. A larger-than-needed screw compressor installed in a shop environment can accumulate many unloaded run time hours of double the waste if the average flow is low. If this is the case, it pays to purchase two smaller compressors rather than one large one. And if a larger-than-normal storage receiver is installed with the compressor, a screw compressor can run in start/stop mode just like a reciprocating unit. Another solution might be to purchase a variable speed drive compressor which may eliminate unloaded run time altogether.