Simulation is a Window into the Future of Your Manufacturing Operation

By Travis Hill, Senior Engineering Project Manager, Mississippi State University

The National Academy of Engineering and the National Research Council have identified enterprise modeling and simulation as a technological breakthrough that will have a profound impact on manufacturing performance. Perhaps you are among the many small and medium-sized manufacturers (SMMs) who are aware that simulation provides a low-cost, secure, and fast analysis tool for product design and verification. But you may not be aware of the powerful impact it will have on the manufacturing of a product and even greater prospective impact across your business. In fact, no other technology offers more potential for improving products, perfecting processes, reducing design-to-manufacturing cycle time, and reducing product realization costs.

Since commissioning new manufacturing facilities, production lines and processes are often costly and capital-intensive, applying simulation methods to manufacturing can yield enormous benefits, including:

- Identifying manufacturing bottlenecks and opportunities to increase throughput

- Uncovering cost-saving opportunities such as optimization of direct and indirect labor

- Validating the expected performance of new and existing production facilities or value streams.

Many large manufacturers in the automotive and aerospace industries have taken advantage of simulation, but SMMs have struggled with the time and level of expertise it takes to build and validate a simulation model, especially for those in high-mix, low-volume environments that are difficult to model adequately. But there is a payoff, as simulation will provide manufacturers with a great opportunity to increase their performance and meet the daunting demands to rapidly introduce new products and technology, reduce costs, and increase quality. SMMs can stay competitive by using advanced engineering tools such as simulation.

Implications for SMMs

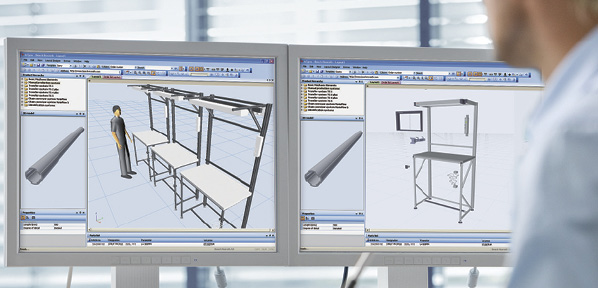

Simulation can drive how you will produce a product. You can provide the customer and internal teams a virtual view of the set up on the facility floor, what resources will be required, and the process flow. If you need to make a change, it’s a simple click, and you’re running a new simulated version.

Simulation can improve your collaboration with customers, equipment vendors, and supply chain partners. It also reduces expenses and disruptions associated with legacy trial and error that often involve changing a factory line setup.

Engineers often are constrained in their thought processes because they are ingrained in the day-to-day operations. Simulation allows them to see how far they can push a system until it breaks or to model alternative processes and materials. The many reasons to simulate include:

- Improve system performance through decision support and training

- Enable sophisticated “what if” analyses

- Deal with the complexities of interdependent variables and dynamics

- Focus attention on detail and improve understanding of a system

Simulation can be used to analyze many aspects of an operation, including:

- Layout: Routings, inventory, batch sizes, cycle times, control systems

- Identify system constraints

- Production changes: Incorporation of new productions, changes in demand pattern, changes to production mix, schedule, and sequence

- System performance: Throughput, capacity, productivity, maintenance, reliability

- Labor: Resource utilization, operator assignment

- Rules and policies

Barriers to implementation

Simulation remains largely underused by SMMs. While it requires collaboration among multiple departments and possibly vendors, the most common barriers to implementation are in these four areas:

- Timeliness. The simulation model development process is labor intensive, which is intimidating for resource-challenged SMMs. Although some complex simulation projects may take months to complete, many questions can be answered in a relatively short period and with little effort. For a mission-critical project, allowing a small amount of extra time for simulation can save a company a lot of money. In addition, much information can be obtained during the construction of a simulation that may prove useful.

- Cost. Many simulation packages cost tens of thousands of dollars for a single license and require high-end computer hardware. Although all of this is expensive, ultimately a manufacturer must do a return-on-investment analysis to decide whether to purchase the software or use external consultants. The goal should be to make simulation a part of the SMM’s culture. That is why it is recommended that the manufacturer has someone trained in simulation to effectively manage simulation projects, whether they are building simulation models or managing any external consultants.

- Project management. Issues may arise from a lack of trust or understanding of the technology. Senior management might have a general distrust of new methods and technologies, or a general misunderstanding of what simulation can and cannot do. Although any scenario can be simulated, simulation is not necessarily the best solution for all problems.

- Technical skills. Learning simulation methodologies and software are only part of what is required to be an effective modeler. Simulation modelers must be able to build a model and interpret the results. They must be able to troubleshoot problems in the model and on the shop floor. The problem solving and troubleshooting skills take time to hone.

Detailed view of your operation

The power of simulation is almost a requirement these days because it forces attention to detail and provides a window into your processes. It documents nuances. It will help you learn more about your operation. You can see the interaction of how one process impacts another that you would not be able to see on a spreadsheet of data.

Yes, simulation has a big upfront cost, but it lowers the barrier for subsequent analysis. Like any worthwhile investment, simulation requires education and buy-in. If you have a lean operation and an engineering presence, you may have a higher level of readiness for simulation. In any case, you will start with a model based on the big picture. And while building the initial model takes the most time, as the quality of input is key, it provides the ability to run many scenarios.

Most SMMs start with smaller projects, such as simulating the tool path of a part, or applying heat algorithms to see if a part will warp or wear. But you will soon be able to take on more complex simulations, perhaps improving your material handling by determining whether to move work pieces by line or crane.

Simulation’s long-term potential is unmatched in terms of transforming your manufacturing operations.

Not sure how to get started with enterprise modeling and simulation? MEP National Network experts can help. You can reach out to one of the 51 MEP Centers, located in all 50 states and Puerto Rico for more insights and informational resources.

For more information, visit www.nist.gov/.