Vacuum Pick & Place: Direct Food & Drug Contact

By Dane Spivak, Davasol Inc.

The food and medical industries hold themselves to higher standards than most. Over the years, many of these manufacturing standards have been adopted at the corporate, national, and global levels with the purpose of providing the consumer consistent and safe-to-use products. Vacuum pick and place involving direct food or drug contact is a familiar manufacturing process applied around the world. The following article shares techniques to design successful vacuum pick and place systems while adhering to industry requirements.

Like most applications, the first instinct is to select a vacuum cup that will create a good seal and allow for a confident grip on the part. However, given the cup will be in direct contact with a product to be ingested, we must first find the appropriate credentials to allow for safe contact.

The Food and Drug Administration (FDA) is an agency based in the United States that is responsible for public health by assuring foods are safe, wholesome, sanitary and properly labeled.1 The FDA compliances have grown globally due to the large amounts of imports and exports throughout the world, and therefore many companies practice their policies. Other agencies and policies exist though the FDA is most popular and relevant particularly in North America.

The standard for suction cup material is FDA 21 CFR 177.2600. The primary need for FDA compliant vacuum cup material is, first, to ensure it is safe, and second, to allow for only a minimal amount of material to be leeched off the cup and onto the product. The maximum allowable amount of leeched material for approval is extremely low, which would be deemed virtually non-existent. The go-to material for food grade cups is silicone, which is used in most applications. But be careful, just because a cup is made of silicone does not necessarily mean it is FDA compliant. Manufacturers of vacuum cups often list FDA cup material compliant models. Users may request the FDA material compliance certificate from the manufacturer for verification.

Silicone cups are often white or red in color though many other colors exist. White tends to be the color of choice for direct food contact though the cup color does not determine its suitability for FDA contrary to what is believed. Depending on the product, certain colors are chosen to be able to distinguish between the cup and the food. For example, a green cup would not be ideal to pick cucumbers. A red color would be better suited so the cup can be seen and identified should a piece fall off the machinery.

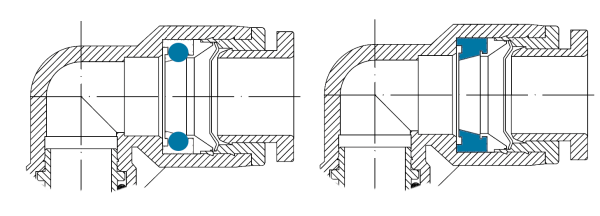

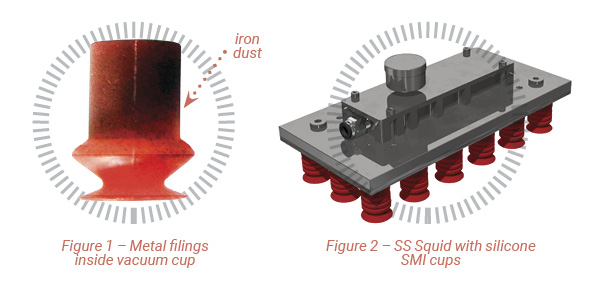

On the subject of cups or pieces of a cup falling from the machinery, it is important to identify the situation quickly and locate the unwanted cup pieces. Product recalls happen on a regular basis, and in food and medical, it can very well be the cause of a vacuum cup getting lost in product packaging. There have been instances where millions of dollars’ worth of food products are recalled. A common solution to avoid this problem is using metal detectable vacuum cups. These are vacuum cups where iron dust is incorporated inside the compound as shown in Figure 1.

At some point after the pick and place process is complete, all products are run through a metal detection device. Should a cup piece, or any metal component for that matter, trigger the detector, the product or product package can be identified and dealt with accordingly. Conveniently enough, silicone cup materials can be metal impregnated and meet the FDA compliance as well. The result is a metal detectable FDA compliant silicone cup, which is a popular choice among users and machine builders when dealing with vacuum pick and place applications for direct food contact.

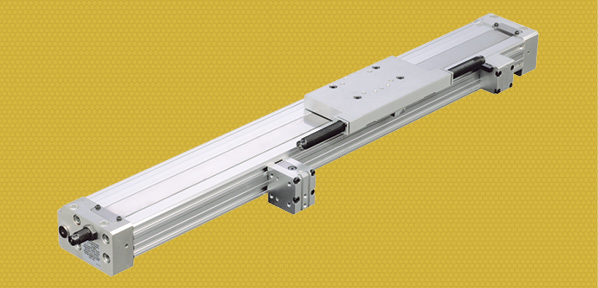

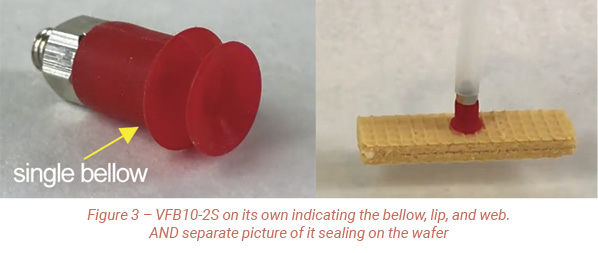

Depending on the organization, the tool and other surrounding components may also require these characteristics even though they are not in direct contact with the food. For that reason, these parts are often made of specific materials to meet manufacturer’s needs as well. Stainless steel being the leading and obvious choice of material. Figure 2 shows a vacuum tool in stainless steel that uses food grade metal detectable vacuum cups. Stainless steel also offers washdown resistance, which is often needed in unpackaged areas of the food manufacturing process.

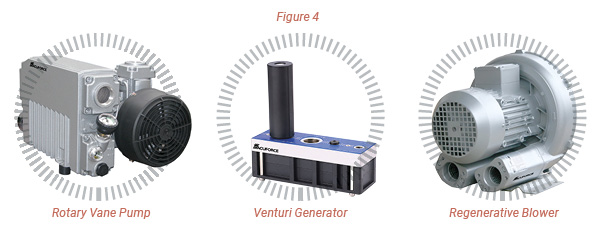

Now that we have checked off the list of standards, we can move on to designing a system to pick and place the food or medical goods. The nature of these product surfaces tends to be curved, uneven, or rough, so selecting an appropriate vacuum cup to create a good seal is essential. For these reasons, bellows vacuum cups are more common than flat cups. Bellows refers to the fold(s) in the cup that allow for height and angular compensation, as well as a protruding sealing lip. Figure 3 shows a single bellow vacuum cup sealing against a wafer bar. The bellow allows the cup lip to deform to the wafer surface, which offers a good seal.

Figure 3 demonstrates the use of a typical 10mm single bellow vacuum cup, though many different shapes and sizes of cups exist. Some with many more bellows that offer additional height and angular compensations; others with varying lip and web thicknesses providing different sealing capabilities. Choosing the best vacuum cup by eye can be difficult. To ensure the proper selection is made, testing is recommended for confirmation of a secure product grip.

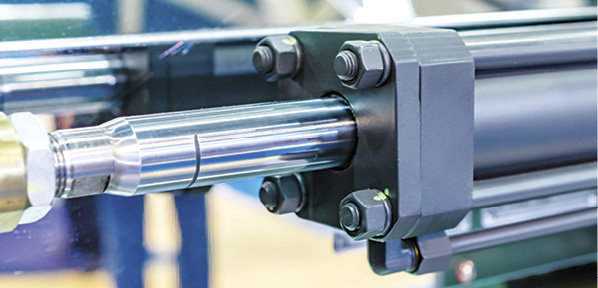

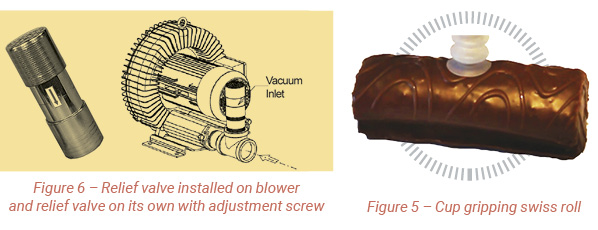

Vacuum pumps or generator units work in conjunction with the vacuum cups to create a seal on the product. Selecting the pump type and size determines how the cups interact with the food and overall system performance. Typical vacuum generation units in the food and medical industries are venturi generators, vane pumps, and regenerative blowers. Examples are shown in Figure 4.

Considering many food products are lightweight with irregular surfaces, vacuum flow is the key performance feature. Vacuum flow is the rate at which air is removed from the vacuum system. Higher flows can help cups engage in a better seal and also compensates for other leakage present in the system, such as porosity or cups that are not sealed altogether. Vacuum levels are what determines the lifting force a cup can provide, but without the right amount of flow to create a good seal, the vacuum level could remain at zero. When dealing with lightweight products, higher vacuum levels of 24”Hg (80% vacuum) are not needed and sometimes undesirable. The higher the vacuum level, the higher the exerted pressure the product experiences. This can be detrimental to the food surface by leaving a mark or causing damage. Figure 5 shows a multiple bellows vacuum cup lifting a swiss roll. The lightweight swiss roll has a delicate surface, and therefore a low vacuum level is used for this application.

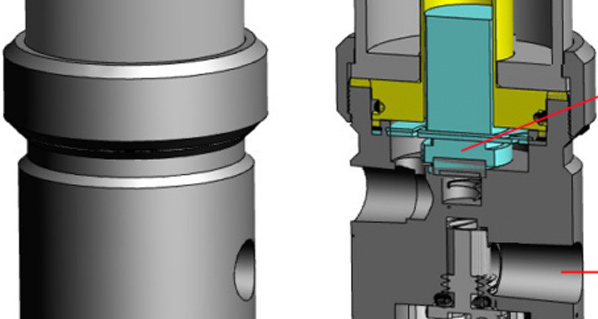

Regenerative blowers, sometimes referred to as side channel blowers, are a popular choice for vacuum pick and place in direct food contact applications. Blowers provide relatively high flows while using little energy and generate low-to-middle ranged vacuum levels, precisely the performance needed for the reasons described in the previous paragraph. Blowers are usually coupled with a vacuum relief valve whose primary job is to relieve pressure in the blower should it climb too high (Figure 6). This is accomplished by allowing atmospheric air to bleed through the relief valve and back into the pump. Most relief valves are adjustable, which can offer the user flexibility as the relief valve can be metered to change the maximum allowable vacuum level. To add to its versatility, some blowers can also use variable frequency drives to increase or decrease the flow and vacuum levels.

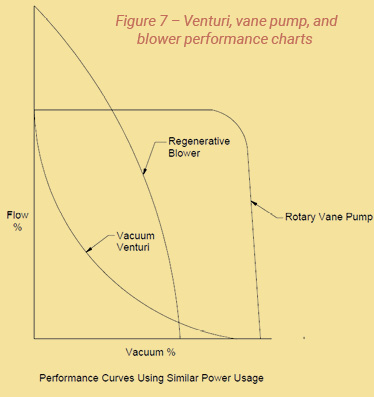

Venturis and vane pumps are also used in food pick and place applications. When comparing similar power rated units, they offer less flow, but higher vacuum levels than blowers. These units are better suited for applications where the product is heavier, and the surface is easy to seal against. Venturis use compressed air to create a vacuum and are not good at generating flow at higher vacuum levels. They are also usually designed to reach vacuum levels of 24”Hg (80% vacuum) or higher. Vane pumps are electrically powered liked blowers, but do not operate well under approximately 21”Hg (70% vacuum). Lower vacuum levels can cause unwanted vibrations and oil leaks. Vane pumps can be quite large and provide high flows, but not nearly as efficiently as blowers. Comparable performance graphs are shown in Figure 7.

Venturis and vane pumps are also used in food pick and place applications. When comparing similar power rated units, they offer less flow, but higher vacuum levels than blowers. These units are better suited for applications where the product is heavier, and the surface is easy to seal against. Venturis use compressed air to create a vacuum and are not good at generating flow at higher vacuum levels. They are also usually designed to reach vacuum levels of 24”Hg (80% vacuum) or higher. Vane pumps are electrically powered liked blowers, but do not operate well under approximately 21”Hg (70% vacuum). Lower vacuum levels can cause unwanted vibrations and oil leaks. Vane pumps can be quite large and provide high flows, but not nearly as efficiently as blowers. Comparable performance graphs are shown in Figure 7.

The food and medical sectors certainly have high standards and expectation of quality products. All for justifiable reasons. This article covered methods in vacuum pick and place to meet the needs of the industries while providing a technically sound solution. Standards are constantly changing by company and geographical location. Professional help should be sought to ensure the appropriate solution is implemented.

1 Reference: https://www.fda.gov/about-fda/fda-basics/what-does-fda-do