Sustainable Solution: A Versatile Hydraulic Option

By Carl Richter, Vice President and General Manager, Kyntronics

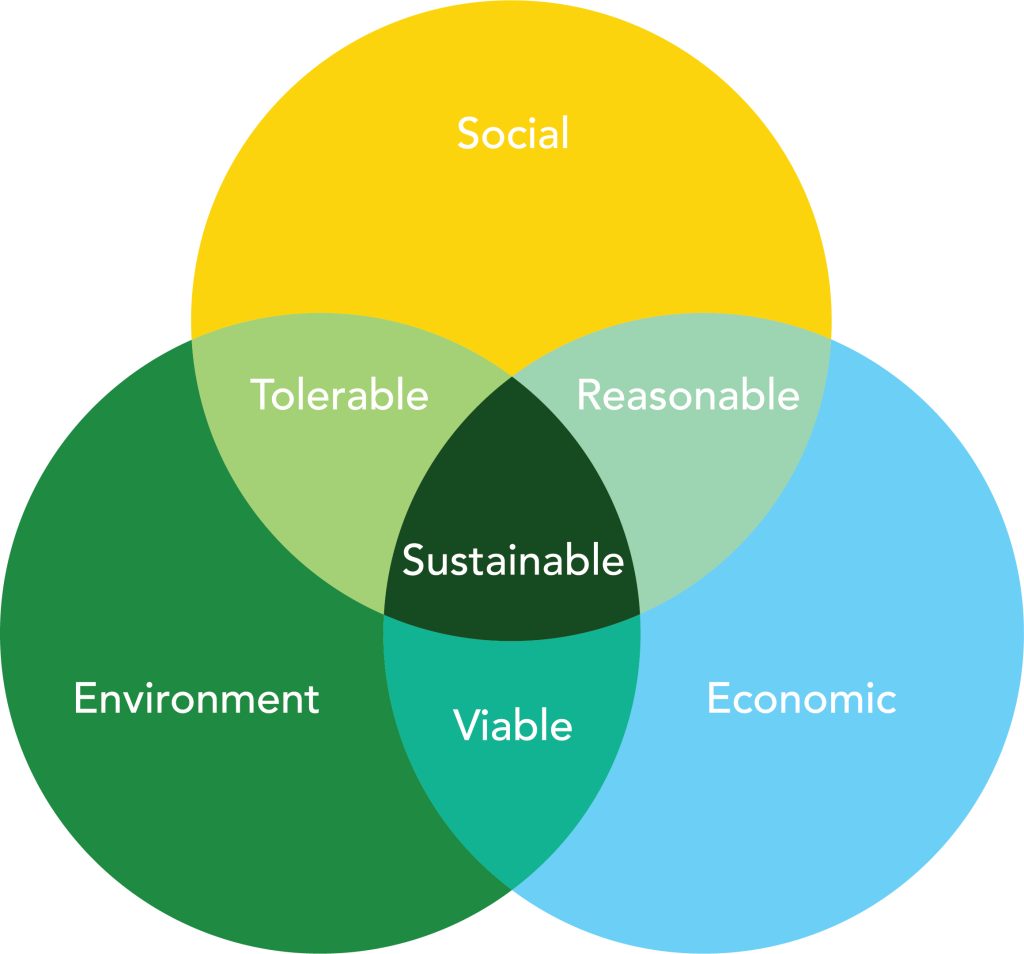

Sustainable manufacturing is being promoted globally. Some companies feel it is important regardless of the costs, others do what makes sense, and still others are on the sidelines and unsure of the available options.

The U.S. Environmental Protection Agency defines sustainable manufacturing as “the creation of manufactured products through economically sound processes that minimize negative environmental impacts while conserving energy and natural resources. Sustainable manufacturing also enhances employee, community, and product safety.”

Regarding hydraulics, we can focus on three basic principles: social, environmental, and economic. The sustainability message helps a company focus on the long term, increasing efficiency, eliminating waste, and providing a safer environment for employees while strengthening the company’s brand,

With existing hydraulic systems operating throughout the world there is always room for improvements regarding sustainable manufacturing. At the end of the day, for most companies it is about production, how many parts per shift and per day, and so forth. Changing machines is costly and may not make sense in the short term. Many companies are reviewing alternative options for new builds or upgrades and how to make them more sustainable.

For hydraulics, options available today include electromechanical actuators (EMAs). Some companies have tried EMAs with limited success. Many EMAs are not up to the hydraulic robustness or are not cost effective. Other options include techniques to make the hydraulic power unit more efficient, such as installing a timer to turn off the HPU motor when not operating for so many minutes. Or using a variable-frequency drive to control a pump motor or implement servo-controlled HPUs. The servo power unit is becoming popular; it minimizes or eliminates hoses and hydraulic connections and provides power on demand while offering more control capabilities.

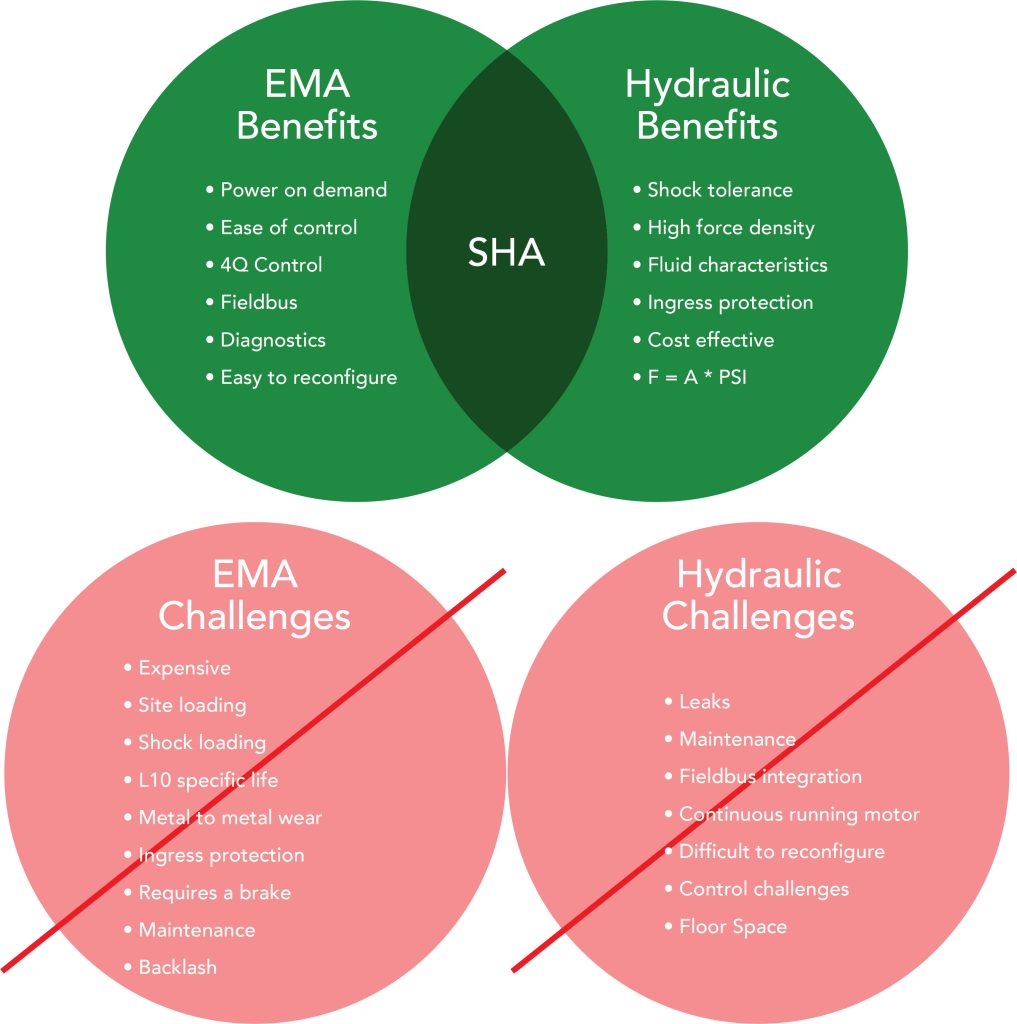

What if there was a technology that combines the best features of hydraulics and the electromechanical technologies? And what if that technology also reduces the challenges? The Kyntronics

smart hydraulic actuator (SHA) is an ideal solution for sustainable manufacturing.

SHA technology contributes to sustainability momentum in five key factors that support the basic principles: environmental, reducing waste and pollution, reducing energy usage, saving time and money, and the human factor.

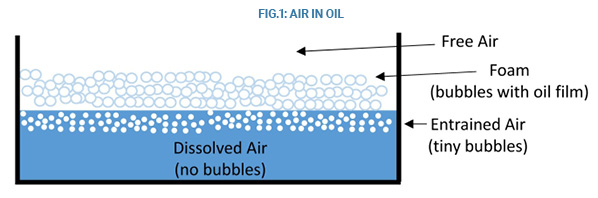

Environmental. The SHA is a self-contained hydraulic actuator that discharges no contamination, doesn’t leak, and uses a minimal amount of fluid. Even with a catastrophic tow-motor incident, a mop can clean up most spills.

Reducing waste and pollution. SHA fluid does not need to be replenished on a regular basis.

Reducing energy usage. The SHA is a power-on-demand device that only uses power when it is needed and is therefore an efficient actuation solution. Compared to a typical continuously running 15-horsepower HPU, an SHA can save around $8,000 per year in energy costs.

Saving time and money. With the SHA, the hydraulic infrastructure design time is eliminated, as are maintenance challenges. The SHA is simple to install. Bolt it up, connect the wires, setup the parameters, connect the fieldbus as needed, and it is ready to perform.

The human factor. The human factor is an important but forgotten part of sustainability. As mentioned, the SHA eliminates dangerous slippery surfaces. There is no worker contamination from continuous cleaning. The SHA is a significantly quieter solution, and noise is substantially reduced by the power-on-demand. With the lower-decibel servo solution, the factory is a much safer, quieter environment.

The SHA is a versatile solution that combines benefits from established successful technologies while solving sustainability challenges. It meets current needs and will help future generations to meet theirs. The SHA is one small tool in a toolbox that can make a change.