Take Your Hydraulic Systems Off Life Support

Contamination in hydraulic fluid is responsible for more than 80% of hydraulic system issues. The most cost-effective method of increasing the lifetime of hydraulic system components is effective contamination control through a comprehensive fluid cleanliness program. This program should begin with contamination and condition control and continue with monitoring results with regular sampling and analysis.

In a perfect world, we would use perfect technology and remove all contaminants from all of our fluids. Unfortunately, we don’t live in a perfect world, so we need to consider factors like the practical limits of filtration technology and cost when developing a cleanliness strategy.

With today’s technology, it is possible to clean fluid to the point at which contamination is not a factor in the failure of any system component that has not reached the end of its practical useful life anyway. This is a practical and achievable goal. Reaching it begins with setting a target cleanliness level based on all the relevant factors affecting the operation of a specific hydraulic system.

In this context, cleanliness is a very precisely defined, quantitative value specified by ISO standard 4406 and based on the results of an approved laboratory particle-counting procedure. While the procedural details are too complex to describe here, the important fact is that it results in a cleanliness code that represents the number of particles of a specific size present in the sample.

Appropriate Cleanliness

Determining the appropriate cleanliness level for a system is a systematic procedure. Virtually all major filtration suppliers produce charts and guidelines to assist in identifying the most contamination-sensitive components in a system and defining the cleanliness levels necessary to maximize useful life.

Once reasonable cleanliness goals are established, it’s time to develop a strategy to implement them. There are two phases: (1) contamination control, which seeks to keep contaminants from getting into fluids in the first place, and (2) contamination management, which seeks to remove those that do inevitably find their way into a system before they can damage it. They are equally important, and an effective system rigorously implements both.

How to Monitor Condition

But, either of those things can’t be done effectively without a way to measure the current condition of fluids. Until recently, that has meant taking samples and sending them off to a specialized laboratory, like Eaton’s Internormen fluid analysis service.

In the last few years, however, a number of manufacturers have introduced highly capable, portable systems that duplicate much of the analytical capability offered by traditional lab-based services. Note the word “much” because there still are some important tests that, so far anyway, only can be done in a laboratory. None of these systems eliminate the need for periodic laboratory tests; they simply change the frequency with which they are required and the nature of the tests performed.

What today’s portable systems do accomplish, however, is making scheduled condition monitoring, as opposed to simple periodic testing, a viable process for even small fleets. A condition-monitoring program makes it practical to make near-real-time maintenance decisions based on the actual condition of hydraulic fluids and other lubricants.

The difference in results between a maintenance program based on condition monitoring and one based on traditional time or process-based preventive procedures can be significant. The goal of condition-based maintenance is to prevent system or equipment failures before they happen by replacing worn components before they fail and thereby ensuring maximum system or equipment availability.

Practical experience shows that condition-based maintenance can extend the useful life of a piece of equipment by 30 – 40% compared to a poorly maintained one. That is on top of the economic benefit of increased uptime and availability for the well-maintained equipment and the virtual elimination of unscheduled maintenance downtime.

A Laboratory in a Suitcase

The heart of any condition-based maintenance program is the “laboratory-in a-suitcase” that is used to determine fluid condition in real-time in the field. One example is the OCM 01 condition monitoring system from Eaton’s Internormen product line.

It is flexible enough to work in suction or pressure mode, as well as handling traditional bottle samples. This compact machine can measure

- contamination classes according to ISO 4406:99, SAE AS 4059, NAS 1638 protocols;

- dynamic viscosity in mpas;

- temperature in °C and °F;

- water saturation in % and, for certain fluids, the theoretical absolute water content in ppm; and

- relative dielectricity.

Users get simultaneous instant readings of particulate contamination and fluid aging with a single measurement. The system has a color LCD display and software to guide an operator through the test procedure. It also has integral data-storage capabilities, is able to write to USB flash drives, and can transfer data to computers via LabVIEW-based software and an RS-232 interface.

In practice, the system is ideally used to document the condition of any new system and any system that has been opened to the atmosphere for maintenance or immediately after fluid replacement to provide a baseline against which to compare future readings. Then the system is periodically re-tested according to a schedule based on operating experience and the cleanliness recommendations of various component manufacturers.

It’s worth noting that condition monitoring is an important tool for extending the life of equipment other than hydraulic systems. Eaton’s OCM 01, for example, can be used to test foamed oils in the lubrication systems of large gearboxes typically found in wind power nacelles, ships, and steel works.

Immediate Diagnosis

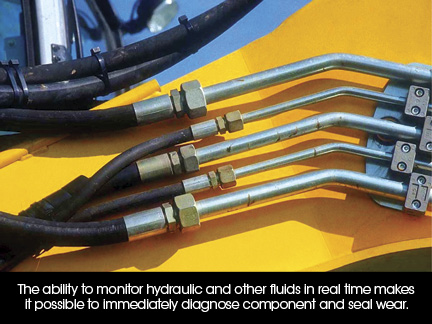

The ability to monitor hydraulic and other fluids in real-time makes it possible to immediately diagnose component and seal wear, as well as provide a quantifiable basis for filter and fluid change intervals. Beyond that, the ease and simplicity of the testing procedure makes it practical to test and evaluate the impact of operational and environmental variables on overall system performance and operating cost.

The ability to monitor hydraulic and other fluids in real-time makes it possible to immediately diagnose component and seal wear, as well as provide a quantifiable basis for filter and fluid change intervals. Beyond that, the ease and simplicity of the testing procedure makes it practical to test and evaluate the impact of operational and environmental variables on overall system performance and operating cost.

For example, with a laboratory-in-a-suitcase available, it is completely practical to test the condition of new fluids as they are introduced into a system to verify the effectiveness of off-line filtration systems and the correct storage and transport of the fluids. The difference between knowing the condition of new fluids and waiting for a laboratory analysis could easily be the difference between an efficient, reliable system and an early failure.

The convenience and flexibility offered by these devices also eliminates many of the either/or decisions that often constrain laboratory sampling. For example, if only one sample can be sent to the laboratory, should it be taken from the reservoir, or the pump outlet, or the return line, or somewhere else?

A fluid analysis professional will say “all of the above” if you want a really useful, accurate insight into the condition of a system. That’s probably not cost-effective on a routine basis using a professional lab, but it is easily accomplished with a laboratory-in-a-suitcase. In many cases, an advanced warning that prevented a major field failure would more than justify the cost of the testing equipment.

Key Points

- A laboratory-in-a-suitcase will not eliminate the need for routine maintenance, but it will make the process more efficient and cost-effective.

- It will not eliminate normal component wear and tear, but it will make the consequences more predictable and easier to avoid.

- It will not eliminate the need for detailed laboratory testing, but it will reduce the frequency with which it needs to be done.

- What it will do is dramatically reduce the incidence of catastrophic equipment failures, streamline maintenance scheduling, and maximize equipment uptime and availability. Those things, of course, will have an important positive impact on the bottom line.