Test Your Skills: The Application of Fluids

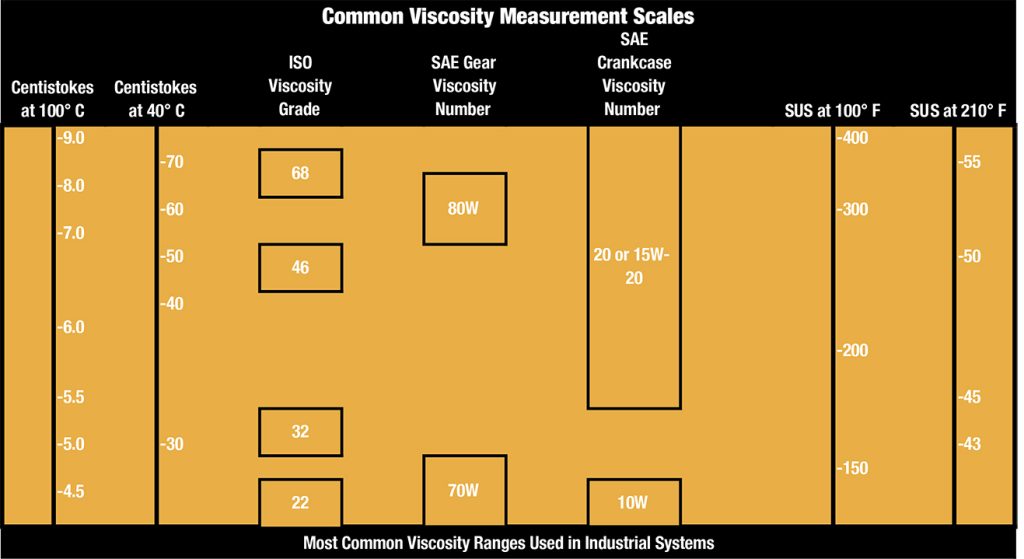

Selection of viscosity must be made with the normal operating temperature of the machine in mind. The temperature is usually measured at the pump. The correct viscosity at the expected operating temperature will allow the fluid to transmit the power most efficiently while still lubricating and cooling the machine without exhibiting excessive leakage. If the viscosity is too high (the fluid is too thick), the operation of the machine will be sluggish and excessive heat will be generated as the fluid flows through the system. If the fluid is not viscous enough, the fluid will bypass the close-

Selection of viscosity must be made with the normal operating temperature of the machine in mind. The temperature is usually measured at the pump. The correct viscosity at the expected operating temperature will allow the fluid to transmit the power most efficiently while still lubricating and cooling the machine without exhibiting excessive leakage. If the viscosity is too high (the fluid is too thick), the operation of the machine will be sluggish and excessive heat will be generated as the fluid flows through the system. If the fluid is not viscous enough, the fluid will bypass the close-

fitting parts of components. This leakage is called slippage. As the fluid leaks internally from areas of high pressure to areas of lower pressure, heat will be generated. External leakage may occur as well, as the fluid may be thin enough to bypass seals.

Liquids used for hydraulic fluids include petroleum-based oils, synthetics, water-glycols, oil-in-water, and water-in-oil emulsions, and high water content fluids. It is estimated that about 80% of the hydraulic fluid sold each year is petroleum-based oil, with the remaining 20% being the other four types, which are also fire resistant. Industries that use fire-resistant fluids include forging and extrusion, coal mining, chemical-petroleum power, die casting, foundries, metal fabrication, plastic injection molding, and primary metals manufacturing.

Petroleum-based hydraulic fluids, refined from selected crude oil, are formulated with an additive package to reduce friction, wear, rust, oxidation, and foaming. Acidity and viscosity improvers help to maintain the viscosity between narrow limits at the expected operating temperature. If the fluid thins out excessively as the machine comes to operating temperature, the volumetric efficiency of the pump and actuators decreases, and the likelihood of internal leaks increases.

Petroleum oil has the natural ability to transmit power, has good lubrication properties, dissipates heat reasonably well under in-plant operating conditions, and is compatible with most sealing materials. As long as the temperature is held below 140°F (60°C) and the oil is kept free of contaminants, petroleum-based fluids are long lasting and stable. If there is a catastrophic failure of the pump, the system must be properly flushed and new, filtered fluid must be added to prevent contaminating the new pump and other components. The condition of the fluid should be determined by periodically analyzing samples.

There is a misconception that fire-resistant fluids will not burn. Most hydraulic fluids will burn if the temperature is high enough. What fire resistance means is that the fluid will not continue to burn once the source of ignition is removed. Straight synthetics are used where a fire hazard exists and where the high cost of the fluid is not prohibitive. Water-glycols and water-in-oil emulsions reduce the possibility of ignition. High temperature will evaporate the water component of the fluid, removing heat from the reaction. High water content fluids are the most fire resistant because the water-content-to-additive ratio is too high for the additive to ignite.

Oil-in-water emulsions surround the oil molecules with water, making water the continuous phase. Oil-in-water emulsions are used primarily for cooling, such as in cutting oils and coolants. Water-in-oil emulsions are mixtures of oil and water with the oil surrounding the water droplets. Thus, the oil is the continuous phase, which usually gives superior lubricating quality. Water-in-oil emulsions are called invert emulsions.

Water-glycol fluids are designed for use in hydraulic systems operating in areas with a source of heat, ignition, or where there is a potential fire hazard. They are a mixture of water, ethylene glycol, and high-viscosity lubricating and thickening agents, along with additives to prevent corrosion. Most water-glycol fluids are limited to use in low to medium pressure and noncritical applications because their water content limits their lubricating and wear-resistance characteristics. The use of water-glycol fluids may require lower operating pressures and rotational speeds based on manufacturer’s recommendations. Water-glycol fluids attack zinc, cadmium, and aluminum, so these elements must not be located anywhere in the system in order to prevent contamination and deterioration of the hydraulic system. Usually, no special hoses, seals or packing materials are required when changing over from hydraulic oil, although neoprene, Buna N, and Viton are the most common compounds used for seals. However, it is best to check with the fluid supplier to verify this information. Commonly nylon, butyl, or neoprene are used in hose construction. The high water content in water-glycol fluids excludes the use of leather, cork, untreated cotton, and cellulose packing. Water-glycol fluids will also dissolve certain pipe sealing compounds, as will phosphate ester fluids. Only compatible pipe sealing compounds and dopes may be used. Water-glycol fluids have low toxicity and are not irritants to the skin.

High water content fluids (HWCF) are relatively inexpensive and have excellent fire-resistant qualities. Lubrication quality and viscosity stability under severe use and at elevated temperatures depend on which fluid additives are used. Because 90% of the fluid is water, HWCF has excellent heat transfer qualities, but the temperature must be kept within the range of 40°F to 120°F (4.4°C to 48.8°C) to prevent freezing and evaporation. Because the viscosity is typically low, HWCF tends to scour the system and carry foreign particles. For this reason, fine filtration is recommended. Also, because the water content is very high, the fluid must be closely monitored to keep the additive level at the proper balance and to control the microbe level. Because the specific gravity of high water base fluids is much greater than that of petroleum base fluid, it is highly recommended that reservoirs be mounted above the pump to prevent cavitation.

Environmentally friendly fluid

There are an increasing number of fluids being made available that have a reduced impact on the environment. Referred to as biodegradable and/or nontoxic, these fluids are designed to have a limited effect on vegetation and animal life. These terms are not absolute, and care must be given to be sure the product is appropriate for the specific application. This includes the potential environmental impact as well as lubricity and chemical compatibility with hydraulic components. These fluids range from food-grade vegetable oils with limited useful temperature characteristics to engineered products with wide viscosity and temperature ranges. Most of the environmental fluids have high flash points designed for use where good fire resistance is important. Some of these fluids may require a reduction in the pressure and speed ratings of pumps and motors. If the choice is made to use or switch to an environmentally acceptable fluid, there are some important issues to consider.

Seal and conductor compatibility. Traditional nitrile (Buna-N) seals may fail quickly when used with environmentally friendly hydraulic fluids. Some fluids may require special seal materials that are formulated specifically to work with them. In addition, the hose material must be compatible with the fluid. The fluid supplier, equipment manufacturer, and seal supplier should all be consulted before converting any system to an environmentally friendly fluid.

System flushing. Although traditional petroleum base fluids will mix readily with environmentally friendly fluids, this should be avoided because the petroleum contamination will nullify the biodegradability and toxicity benefits of the green product. Very thorough system flushing is necessary, and it is often advisable to perform multiple flushes to ensure the system is perfectly clean before adding the environmentally friendly fluid.

Note, especially, that engine oil additives are not compatible with environmentally friendly fluids. Equipment that has been operated with engine oil as a hydraulic fluid requires exceptionally thorough cleaning before the environmentally friendly fluid is installed. Furthermore, virtually all hydraulic components are tested with petroleum base fluids. Any new component being installed on a system using environmentally friendly fluids must be thoroughly flushed prior to installation to avoid contamination.

Maintenance. Filtration requirements are generally the same for petroleum base and environmentally friendly fluids in terms of particle sizes. However, the filter change interval may be different, particularly with fluids that have shorter service life and a tendency to produce varnish and other contaminants. Note also that most environmentally friendly fluids have a higher specific gravity than traditional petroleum-based fluids. This may require adjusting inlet conditions to avoid cavitation.

Always comply with the manufacturer’s recommendations for the use of the fluid and the components that come in contact with the fluid.

The change in viscosity as the temperature of the fluid changes is described by the viscosity index. The viscosity index is a measure of the stability of the viscosity of the fluid between two temperature extremes. As temperature increases, the fluid becomes thinner, and viscosity decreases. The proper viscosity index of a fluid for a particular application is determined from the fluid temperature change requirements of the machine. Industrial production machinery, for example, generally keeps the oil within a narrow temperature range, so a low viscosity index would be suitable. Mobile hydraulic equipment that must operate between freezing or even sub-freezing temperatures to nearly 160°F (71°C) requires a fluid with a stable viscosity over the entire temperature range, calling for a viscosity index of 100 or more. Consult the pump manufacturer’s fluid specifications. •

Test Your Skills

1. A water-in-oil emulsion is:

a. the same as an oil-in-water emulsion.

b. better for cooling than oil-in-water emulsions.

c. better for lubrication than oil-in-water emulsions.

d. a contamination issue that must be resolved.

e. the most effective fluid for removing heat.