The Unvarnished Truth: Contamination Control Makes Servo Valves Click

Richard Trent, Regional Sales Manager, and Raymond Weaver, CFPHS, District Sales Manager, Hy-Pro Filtration

Tissue paper is manufactured by various companies across the globe by complex machines that use hydraulic systems. In most cases these systems contain servo valves. As most fluid power professionals are aware, servo valves have a low tolerance for contaminants and require the cleanest fluid of all hydraulic components. This is due to tight clearances between the various internal parts of the valve. Particles that may be too small to cause issues with most hydraulic components can cause servo valves to operate erratically, which leads to premature failure. Failures with these valves is costly in downtime and valve replacement and repair.

In the spring of 2018, a tissue mill experiencing weekly machine trips that resulted in downtime on one of their machines contacted Hy-Pro. The cause was attributed to issues within the hydraulic control system, which contained multiple servo control valves. Each trip led to hours of troubleshooting and sometimes valve replacement before the machine could be brought back online and into production. The mill was looking for a solution to the trips and valve failures, which were impeding operations and increasing production costs. Their prior efforts of implementing an offline electrostatic filtration system and replacing various components within the system had not produced the desired results.

At the first onsite meeting, we reviewed the root-cause failure analysis of the failed servo. The reports, which were supplied by the valve manufacturer, showed contamination as the root cause of valve failure. The reports also noted the presence of varnish. We also reviewed an oil analysis, which showed elevations in the membrane patch colorimetry (MPC) value and the ISO cleanliness codes. We also learned at this meeting that the hydraulic-fluid manufacturer had recommended that the system be converted from using AW32 to AM68 oil. Further, the oil manufacturer recommended flushing the system with a system cleaner prior to installing the new hydraulic oil to remove as much residual varnish from the system as possible.

After viewing the hydraulic system, the discussion turned toward contamination control. Reducing contamination within the system should result in a reduction of system failures and machine trips. The company wanted a total contamination control regime to achieve a lower operating ISO cleanliness code and also to deal with varnish.

The mill had installed an offline electrostatic filtration system onto the system sometime in the past to combat varnish. ASTM International uses ASTM.D02C.01 to define varnish, and ASTM D7843 covers MPC. The MPC test has become known as the varnish potential test. Essentially it involves diluting 50 ml of in-service oil with 50 ml of a nonpolar solvent. The dilution occurs after the sample has been heated to 150°F (65°C) for 24 hours and then aged at 70°F (21°C) for 68-76 hours. Once it is diluted, the fluid is drawn across a filter patch, and filtered solvent is drawn across the patch to remove any residual oil. The patch is allowed to dry and then placed onto a sheet of aluminum foil along with a clean white patch. A device called a spectrophotometer then determines the delta E between the two patches, with the white patch being used to calibrate the spectrophotometer. The delta E values can range from 0 to > 100. The higher the delta E, the higher the potential for varnish to form.

Note that the results are not yes or no for varnish. We’ve seen systems with the same lubricant exude no evidence of varnish even though they had delta E values greater than systems with lower delta E values that were also experiencing varnish-related failures. It is our opinion that MPC should be held as low as possible, with the trend being constant as opposed to increasing over time.

Oxidation by-products

In short, varnish is the result of oxidation by-products precipitating out of solution with the fluid itself. Lubricants and hydraulic fluids oxidize over time. Oxidation can be described as the loss of an electron in the presence of oxygen. Mineral-based lubricants and hydraulic fluids contain antioxidant additives (AO) to arrest oxidized molecules and decrease the rate of oxidation. Other things that lead to increased oxidation include excessive heat as well as water and other contaminants.

As oxidation continues to occur, it creates more by-products. Eventually a point can be reached where there are more oxidation by-products present than the fluid can hold in solution. These oxidation by-products precipitate out of solution and begin to plate onto various metal surfaces. At this point varnish begins to form in the system. If the situation continues unchecked, it shortens the life of the components and the fluid itself.

Areas that generally collect varnish first are areas of low flow (reservoir), areas of tight clearances (servo valves), and cooler areas of the system (heat exchangers). Varnish has an interesting relationship with temperature. Fluids can maintain more oxidation by-products at higher temperatures versus lower temperatures. This explains why varnish appears where it does, as precipitation can more easily occur in these locations.

Varnish formation within hydraulic fluid is a broad and complicated subject. We discuss it in this article for simplicity and expediency, since varnish was a major factor in the machine trips and servo valve failures in the tissue mill’s hydraulic control system. We now look at varnish mitigation and the subsequent results at this mill.

We now know that varnish is the result of oxidation and that oxidation within mineral-based lubricants and hydraulic fluids accelerates at temperatures higher than 150°F (65°C). As water and other contaminants accelerate oxidation, a good first step is to keep the fluid clean, dry, and cool. Minimizing oxidation increases the time before a fluid becomes saturated with by-products.

Varnish mitigation

Even with a system operating under the clean-dry-cool parameters above, oxidation will occur. For that reason, varnish mitigation should be considered. There are many types of varnish mitigation systems available. Offline electrostatic filtration was one of the first systems marketed to control varnish. There are multiple manufacturers of electrostatic filtration systems, and Hy-Pro is one of them. These types of systems have been applied to lubricants and hydraulic fluids for a couple of decades. Most of these, including Hy-Pro’s, incorporate a pump that produces flow through the skid. The fluid flows through filter housings installed with collector elements. High-voltage DC current is applied to metal plated within the collectors, and insoluble oxidation by-products are “collected” onto the plates. The drawback of electrostatic filtration units is that they can only remove insoluble oxidation by-products. This leaves the fluid saturated at the temperature at which the fluid is processed. At any point that the temperature decreases, insoluble by-products can precipitate out of solution, and varnish can form. We do not apply electrostatic filtration to mineral-based fluids for this reason.

Other forms of varnish mitigation systems include ion exchange or ion-charged bonding (ICB) resins. Our experience is that resins achieve the lowest MPC values of in-service fluids. We have been supplying offline systems using ICB resins for around 15 years and have achieved great results. These systems work by removing oxidation by-products that are still in solution with the fluid. Once they are removed, the fluid regains solvency and can dissolve almost any existing insoluble oxidation by-products back into solution. From there the resin removes those. We prefer the use of resin technology for R&O fluids, like turbine and compressor oils as well as most synthetic fluids. Resin, however, is not recommended for all fluids, especially most antiwear (AW) hydraulic fluids. In most cases AW additives are polar, and most resins try to remove them while also removing oxidation by-products. There are some exceptions to this, but we recommend never applying a resin to AW oils unless the fluid is tested with the proposed resin. During this type of test, the AW additives in the new fluid are measured pre- and post-treatment to determine if AW additives are being removed.

A third type of varnish mitigation is the use of depth-filter media. This is not the same as typical glass-filter media that most filter manufacturers produce today. This style of depth media can be produced using different types of fibers, both natural and synthetic. Hy-Pro produces a depth media known as VTM. Other manufacturers also make this type of depth media. This style of depth media does more than act as a mechanical filter, and that is an important distinction. As a rule, oxidation by-products are well below 1 micron in size when they precipitate out of solution. That is much smaller than typically mechanical filters can capture. Also, they are most often still in a liquid state at that point. Properly designed depth media provides a place to capture these insoluble by-products. To keep it simple, the by-products plate to the various fibers and stay within the media. Depth media mostly targets insoluble oxidation by-products, but our VTM has shown the ability to decrease acid, leading to the theory that it removes a small number of soluble by-products. VTM and other types of depth media can remove water as well.

Installing VTM

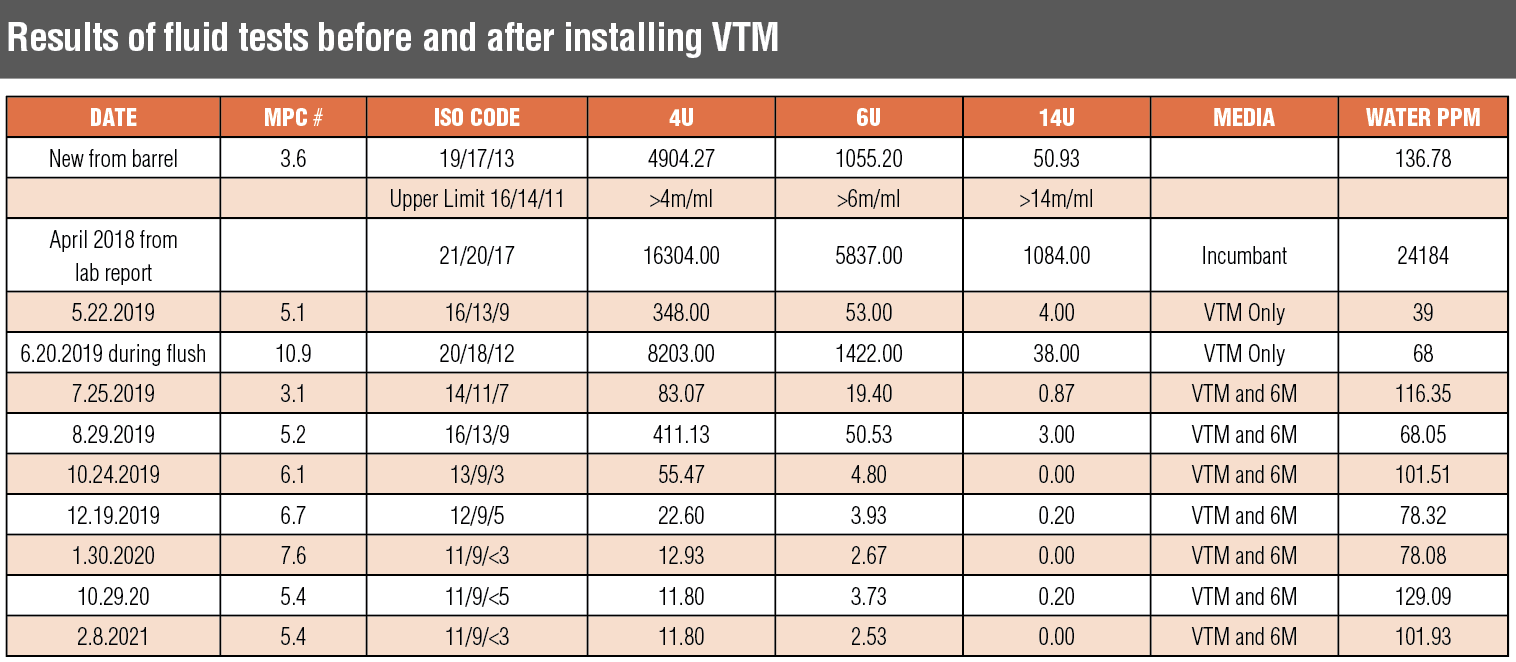

After discussing these points with the mill, the company decided to install VTM onto its hydraulic system. Since the system already contained an offline filter cooling loop, the mill installed a larger filter housing within the loop using this media. After installation, MPC decreased from > 20 to 5.1, and the ISO cleanliness code was 16/13/9 on a sample taken May 22, 2019. Previous samples showed it as high as 21/20/17, with the lowest showing 19/17/12. In June 2019, the oil manufacturer’s recommended cleaning fluid was installed and the system operated for a couple of days. Samples taken on June 20, 2019, showed that MPC had increased to 10.1, indicating the cleaning fluid was doing what it was supposed to do. The June sample showed that ISO cleanliness had increased to 20/18/12.

A sample of the new fluid installed into the system after the flush showed ISO cleanliness as 19/17/13. The next sample, pulled on July 25, 2019, showed MPC at 3.1 and ISO cleanliness at 14/11/7. The most current sample from this system, pulled on Feb. 8, 2021, showed MPC at 5.4 and the ISO cleanliness at 11/9/<3.

From a contamination control point of view, these are great results. The operation results of the system and improved reliability of the hydraulic control system tell the story that matters the most. Since the installation of VTM media, the mill went from experiencing unscheduled downtime of four to six hours per week to a single occurrence as of Feb. 8, 2021. The company applied the same solutions to the other tissue machines onsite.

Arguably, contamination causes most hydraulic component failures. We have reviewed articles that claim that as many as 75% of failures can be attributed to contamination. And it is widely accepted that servo valves have the lowest tolerance for contamination of all hydraulic components.

However, by understanding contamination and developing a clear solution for it, even servo valves can operate for long periods of time. First, work on clean, dry, and cool. Second, implement a control plan that covers all contaminants, including oxidation by-products. It will save money and valuable time.