Steep Slope Tree Harvester Uses Logic Control Solution to Improve Lumberjack Safety

The new ClimbMAX steep slope tree harvester is able to maneuver safely on varied terrain, unlike traditional tree fellers. Designed and manufactured by Trinder Engineering Ltd., a New Zealand-based company specializing in New Zealand forestry customers, the machine relies on a complete hydraulic control solution, developed by Eaton and delivered by Fluid Power Solutions Ltd. The new machine gives forestry companies the ability to safely operate in terrain that was previously unreachable.

With worker safety as a chief concern, forest owners across the globe are constantly looking for methods to protect their employees from dangerous working conditions while increasing harvest yields. In the forestry industry, the monumental physical challenges brought on by steep terrain makes safety concerns even more urgent.

On flat ground, forestry professionals typically rely on harvesting machines to reduce safety risks. On steep hills, however, traditional equipment is not suitable due to lack of stability; sharp angles create issues with traction control and engine and hydraulic oil levels, making traditional machinery a dangerous solution.

Safer, More Efficient Equipment

To enhance safety for forestry professionals, the machine needed to function safely on extreme angles with heavier construction and different boom geometry. The new machine also had to include complex logic control and sensors for self-monitoring, ensuring the machine would stay in place regardless of conditions.

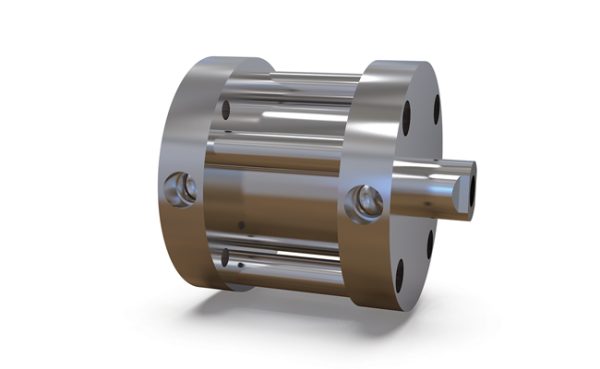

To achieve these goals, the hydraulic system needed a complete redesign to manage the winch system and handle the sharp angles of the boom, which holds the felling head-—a key portion of the cutting operation.

The development was a totally new concept for Trinder, so without any points of comparison for the machine, Trinder invented and built a new harvester by disassembling and rebuilding the flat ground harvester with heavier construction.

Working with distributor Fluid Power Solutions, Eaton delivered a complete control solution package and helped Trinder’s programmer overcome circuit design issues. In addition to a seven-inch Moeller color touch screen, Eaton recommended three controllers, directional control valves, hoses and fittings, and slip-in and screw-in cartridge valves for hydraulic control-—all of which ensure precise control even under the toughest conditions.

A Safe Solution for Tree Harvesting in Rough Terrain

The control system design faced two big challenges. First, the winch needed to be controlled automatically to allow the operator to concentrate on driving the felling machine. Second, the design had to achieve a high standard of safety, giving the operator the confidence to operate the machine on the steepest of slopes with differing ground conditions.

Eaton’s control solution allows the winch and tracks to work in unison with operators, who have the ability to change modes for different terrain and maneuvers by simply pressing one of three buttons conveniently located on one of the joysticks.

The new machine features the option of using the boom to stabilize the machine. The software program embeds the monitoring of all electrical hardware components to ensure that everything is working correctly. There is also a blade on the machine that doubles as a safety device and is automatically driven into the ground to provide stability in case of a power failure.

The harvester is the first of its kind in New Zealand, and forest owners in the country are already stipulating that a winch-assisted machine will be used on slopes over a certain angle. This is likely to become an industry-wide standard. Though it will take years to fully determine how the ClimbMAX machine is helping reduce forestry accidents, its use has already helped minimize the number of lumberjacks who have to work on steep slopes, increasing safety by reducing the potential for accidents.

For more information, visit www.eaton.com.

ben schilling talked to u guys last week just getting my email to you