Watlow’s New HELIMAX Heat Exchanger Reduces Maintenance

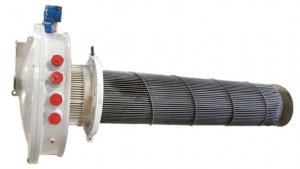

Watlow, a manufacturer of thermal systems, recently introduced its new HELIMAX ultra-efficient electric heat exchanger with Continuous Helical Flow Technology, which helps reduce the coking and fouling typically associated with standard heat exchangers. Diminishing the coking and fouling rates can minimize heat exchanger maintenance intervals ultimately reducing downtime.

Watlow, a manufacturer of thermal systems, recently introduced its new HELIMAX ultra-efficient electric heat exchanger with Continuous Helical Flow Technology, which helps reduce the coking and fouling typically associated with standard heat exchangers. Diminishing the coking and fouling rates can minimize heat exchanger maintenance intervals ultimately reducing downtime.

HELIMAX enables ultrahigh heat transfer rates that lower the skin and shell temperature rise above the process fluid and offers the ability to push the limit on high outlet temperature applications. It also minimizes fluid bypass, assuring tighter sheath temperature control and providing smaller shell diameters. High pressures can often be handled with thinner shell walls or without resorting to expensive exotic materials. HELIMAX is smaller and lighter than traditional heat exchangers, offering significant benefits to space-constrained applications.

For more information visit www.watlow.com.