Aerated Oil on a Log Splitter

I loaned my log splitter to a friend whose tree fell after a storm. The tree was a blue spruce evergreen about 30-ft. tall. It surprised me that the tree’s root system, after 20 years of growth, barely penetrated the ground but seemed to be spread out over a 10 to 12-ft. radius being only about 2 to 6-in. deep.

I loaned my log splitter to a friend whose tree fell after a storm. The tree was a blue spruce evergreen about 30-ft. tall. It surprised me that the tree’s root system, after 20 years of growth, barely penetrated the ground but seemed to be spread out over a 10 to 12-ft. radius being only about 2 to 6-in. deep.

He had cut the tree up in short lengths that would fit into his free-standing fireplace and needed to split and stack the logs. He borrowed my splitter and complained that it slowed down when splitting the logs—slower than it had when he helped me in the past.

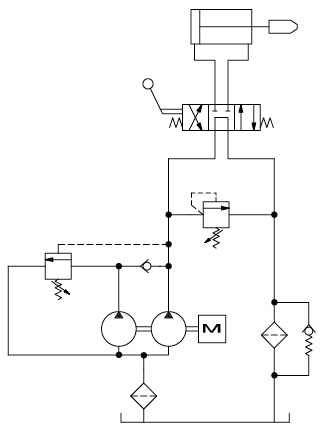

I explained to him that the splitter had a “Hi-Low” pump system with a new cylinder and that it would slow down when it encountered logs that needed pressures higher than 600 psi (see the circuit). He felt this wasn’t the problem, so I went over to his house and looked at the splitter.

He was correct; the splitter encountered the log, slowed down, but eventually split the log. I was sure it was the pump failing, but without a gage or flow meter I removed the pump and took it to my shop for testing. To my surprise, the pump tested out just fine.

Any idea what the problem could be?

See the Solution

The log splitter problem of taking too much time to pressurize and slowing down the cycle time was caused by the oil having excess air mixed with it. The return line was returning oil above the fluid level, aerating the oil. The air slowed down the ability of the oil to pressurize quickly. Filling the tank frame with more oil solved the problem.

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

Clogged suction strainer.