Beware of Getting HOSED

By Jamie Vokes, CFPCC

Various kinds of mobile and industrial equipment use hydraulics in one form or another. While hydraulics is a very efficient use of energy to perform heavy-duty operations, very few people take the time to investigate some of the component parts of a hydraulic system. Even fewer have a formal inspection or maintenance programs in place. This can lead to costly downtime but can also lead to more sinister safety and liability issues.

Who really pays attention to a hydraulic system until it stops working? Some of the common causes of breakdowns include parts wearing out, contamination, oil leakage, or the failure of a part that releases hot oil previously contained at thousands of pounds per square inch.

A pinhole leak in a hydraulic hose that’s under pressure can release fluid at a speed of more than 600 ft per second—which could easily penetrate the skin and enter the bloodstream. (As an example of the personal devastation caused by a safety-related accident in the fluid power industry, refer to “The Effects of Fluid Injection Accidents, An Employee’s Own Story” in the March/April 2011 issue.)

Owning and operating hydraulic equipment requires a maintenance program that is implemented by staff members or contractors who have been fully trained to be aware of the dangers of energy stored inside hydraulic systems. These people also need to be aware of how to safely affect repairs on the machinery or equipment.

Usually the most visible parts of a hydraulic system are the hoses or pipe work, which transfers the high-pressure oil from the pumps and valves to the cylinders, motors, and actuators. The more visible and exposed these parts are, the easier they are to damage or even worse, cause injury.

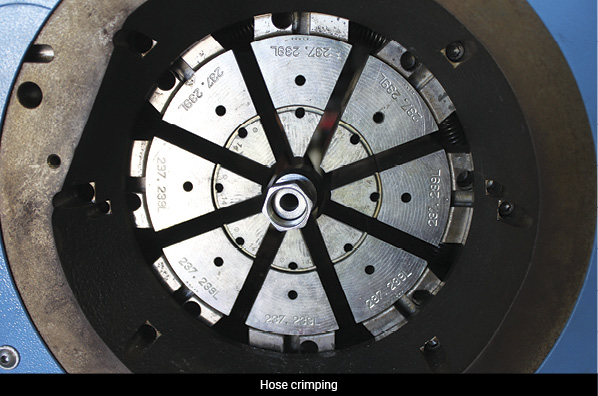

Let’s take a closer look at the flexible hydraulic hoses in these applications. Do you have people within your organization who replace hydraulic hoses or do you subcontract this work out? Over the years, some companies have chosen to purchase a kit that gives them the capability of assembling and crimping hoses in-house. At first glance this may appear to be a very cost effective solution, but is it?

If you make your own hoses have you considered…

Training: Who carries out this task? Is the individual properly trained in the removal and installation and assembly of these hoses? Are they the individual who was originally trained by the vendor who supplied the hose-making equipment or is it somebody else?

Equipment: How old is the equipment? Does it need servicing or regular calibration? Should you be carrying any extra insurances or liability coverage?

Contamination: Do you have a method for cleaning the hose prior to installation on equipment? Debris from cutting a rubber hose is one of the easiest ways to introduce contamination into a hydraulic system. The facility and environment where coils of hose are stored can easily contribute to contamination.

Inventory: Did you know that coils of hydraulic hose have a shelf life? That is why a batch code with a cure date is placed on high-pressure rubber hose. Do you have a system for monitoring the shelf life of your hose inventory? Did you initially get the hose assembly equipment for free providing you purchase the product from the same vendor? This usually means you were loaded up with a lot of inventory that you may not use.

Mixing and Matching: Does your vendor use compatible hose and fittings? Are they manufactured by the same vendor, or are they mixed and matched from different manufacturers? Mixing and Matching can lead to loss of liability coverage and warranty as well as early failure of parts. Or worse, hose assembly failure or even a fatality.

Safety: Making hose assemblies may not be rocket science, however, it is a fact that an incorrectly assembled hydraulic hose could lead to serious injury of your employee, a customer, or even an innocent bystander.

Vendor: Have you asked for the necessary paperwork including safety and training manuals, insurance coverage, source traceability, as well as any relevant MSDS sheets?

By no means does this cover all of the considerations that need to be taken into account if you are deciding to make hoses in-house. They are designed to be a guide in the decision-making process. These points also apply if you go to a hose shop to buy replacement hose assemblies or call out a contractor or mobile service to carry out the repair or installation.

Do not get unexpectedly hosed by finding out that an employee is not properly trained to work on the equipment you operate. If you find yourself visiting them in the emergency room, it is too late.

Do not get unexpectedly hosed by finding out your vendor is mixing and matching parts especially on component hydraulic hose parts. If you find yourself looking at a large claim with no vendor coverage, it is too late.

Do not get unexpectedly hosed by not having the correct paperwork, equipment maintenance programs, and insurance coverage in place. If you are looking back at an OSHA representative without an answer, it is too late.

Safety, training, and the selection of the correct replacement products, services, and vendors to replace hoses and other components in hydraulic systems can save your company the negative publicity of an unfortunate accident associated with high costs of corrective action or a claim that you may find out may not be covered by your vendor or insurance company.

There are many resources available on these subjects on the web.

Good sources of information include SAE (www.sae.org) and ANSI (www.ansi.org) recommendations and regulations, The International Fluid Power Society (www.ifps.org), and the Fluid Power Safety Institute (www.fluidpowersafety.com).