Case Study: Vacuum Solutions Improve Cold-Room Palletizing System

From Piab

Bringing sweet tea and juice to market requires palletizing cases filled with bottles for transportation to retail outlets. Due to their perishable nature, they are stored in cold rooms. A customer turned to Motion Controls Robotics Inc (MCRI) from Fremont, Ohio, to replace an inefficient system in which vacuum cups and pumps did not cope well with the average temperature in the cold room of 35°F (1.7°C), which made the vacuum cups rigid and prevented pumps from providing enough vacuum to hold the cases, all of which resulted in regular drop downs. The customer needed a better system to handle cardboard cases weighing up to 42 pounds (19kg).

The customer’s washdown process excluded any kind of area gripper that consisted of closed-cell technical foam. Fork-style tools were also out due to limited work space.

“It was clear that the only possible solution would be cold-resistant silicone cups and high-quality, powerful vacuum pumps,” said Nathan Baker, a mechanical engineer at MCRI.

Baker contacted Matt McClellan, of Neff Group Distributors in Valley View, Ohio. “He always provides me with multiple product suggestions as well as detailed engineering support. He suggested the SX 12 ejector after further analysis on the most suitable pump with Piab’s technical expert, application engineer Oliver Lizotte, at their Hingham, Massachusetts, office.”

“The SX 12 is the ejector Piab uses in their flagship piCOMPACT23 SMART pump for high vacuum performance,” McClellan said. “It is based on their COAX vacuum generation technology. This ejector was particularly optimized for high reliability, flexibility, high vacuum flow, and fast cycle times. It is specifically recommended for palletizing solutions requiring large vacuum systems. It proved to be the right solution for application case at hand at MCRI.”

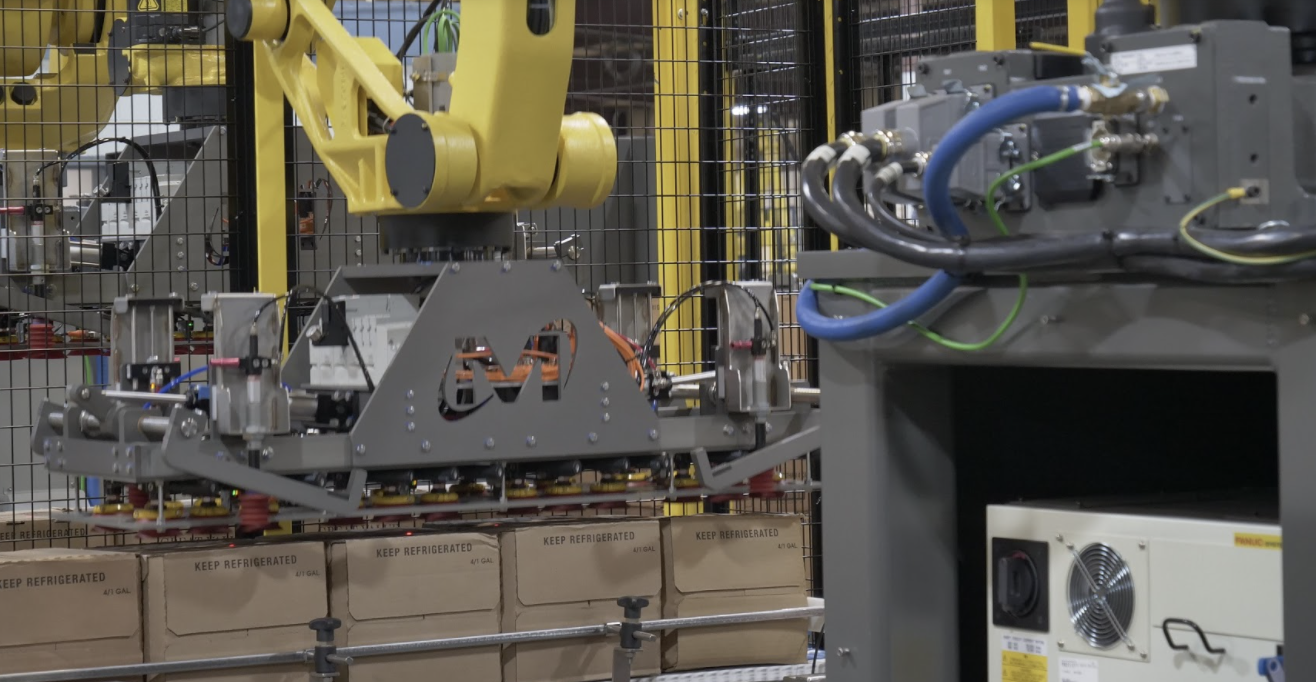

Cold resistant B75.20 silicone cups and powerful SX12 vacuum pumps enable flawless gripping processes.

“Thanks to its higher vacuum flow,” Lizotte said, “the SX12 ejector not only offers a stronger holding force but is also dust and debris tolerant – an important feature in packaging applications dealing with cardboard boxes.”

Cold resistant B75.20 silicone cups and powerful SX12 vacuum pumps from Piab enable flawless gripping processes.

The COAX vacuum technology minimizes energy consumption and offers a safe and quick hold due to the high initial vacuum flow. COAX ejectors are up to twice as fast as other ejectors and deliver three times more volume flow than conventional vacuum ejectors with identical air consumption. The ejectors can deliver high performance even when the supply pressure is low or fluctuating. This has been proven in independent comparative tests at the Fraunhofer Institute for Machine Tools and Forming Technology IWU in Dresden, Germany. The tests have shown that the Piab ejectors require significantly less compressed air than ejectors from other manufacturers to achieve the same performance. Since they have no moving parts, they are also practically maintenance-free and resistant to most environmental conditions, such as cold. They reduce costs for compressed air as well as downtime for maintenance.

“We conducted numerous inhouse tests at MCRI to compare the SX12 holding force with that of the VGS 3010 generator using multiple different cups both in size and style,” Baker said. “The result showed that the selection of the SX12 ejector is perfect. We also tested cups of various material for cold resistance by leaving them in a freezer for one week and then conducting stress and compression tests on the cups. After that we knew that Piab’s silicone B75.20 cup was the right one for this application. These cups are suitable for height differences and slightly uneven or curved surfaces, particularly when several short bellow cups are combined in one lifting device. Piab’s policy of providing suction cups for free for 30 days of testing allowed system integrators to test them in the application to be sure they are the best product for each application.”

The system starts with the robot picking up a pallet and placing it onto a roller conveyor. To do so, the end-of-arm-tool (EOAT) extends four mechanical clamps that grip underneath the pallet top. After the robot places the pallet on the roller conveyor, the robot moves to a plastic belt conveyor, where the cases filled with sweet tea or juice arrive to be palletized. A roll-up door that protects the operator from the running system opens the EOAT and turns to the chain-top conveyor. Using the silicone B75.20 Piab cups, the robot’s EOAT grips a row of four boxes (nearly 170 lbs [77 kg]) and places them on the pallet. After building two layers of product, the robot grabs an intermediate tier sheet by extending four B50 multi-bellow silicone suction cups attached to VGS 3010 pumps placed at the outer corners of the EOAT. The cups perform a slight lifting movement to easily separate the thin tier sheets. For handling lightweight tier sheets, the standard COAX-technology-based ejector performs reliably.

The robot picks up cartons from a plastic belt conveyor where cases are palletized.

The robot picks up the cartons from a plastic belt conveyor from where the cases filled with sweet tea or juice arrive to be palletized.

Two of these palletizing cells are mirrored next to each other, both feeding a finished pallet stretch wrapper through a roll-up safety door. The safety door prevents the operator from entering either palletizing cell.

Baker summarized the improvements in the new palletizing cells, compared to the previous one. “With this case handling setup, we were able to gain an additional 10 pounds (4.5 kg) of holding force per main cup. In fact, we went from dropping nearly every case to a solution that picks any case – even wet cases or cases with cut tape and glue where the flaps are loose. The EOAT with Piab’s B75.20 suction cups and SX12 ejectors still makes the pick!”