Company Profile: Sharon Tube

Sharon Tube, a recognized quality and service leader in the DOM precision tubing industry, recently completed a four-part video series discussing its service capability. The following are responses from the company’s employees discussing how new technology and a committed workforce have allowed them to increase their service capability in ways that stand out in the industry.

How is Sharon Tube different from other DOM manufacturers?

Sharon Tube is different because we’re a company that’s getting bigger while maintaining small company values – overall service to the customer, being close to the customer, listening to the customer, and doing the right things for our work force. We put together these videos to show how this small-mill mentality has allowed us to focus on service first, helping us meet and exceed our customers’ expectations on every order that they place.

What makes Sharon Tube’s workforce stand out in the industry?

Sharon Tube’s workforce is a very committed group of people. The average tenure probably runs 10 to 15 years, and we have a lot of long-term employees who have been here for 20+ years, with an additional 30 years of service from their fathers or other family members. They also recognize the importance of domestic manufacturing and are proud to be an all-American workforce.

How does Sharon Tube’s workforce benefit the customer?

Everyone works under one roof, which allows for us to provide the absolute best service for our customers. We all have a stake in the success of the company and in the satisfaction of our customers. We really do feel like a family with a common objective to satisfy our customers and be a reliable supplier. Additionally, every department — from sales to production planning, to tech services, to the people out on the floor, to management — touches the product or looks at it in some fashion, ensuring that the best possible product is provided to our customers.

How does reliability factor into Sharon Tube’s service capability?

Reliability is key here at Sharon Tube, and it allows us to stand out in the industry with on-time delivery performance and some of the shortest lead times in the industry. If we say we’re going to do something, we do it. And that reliability is the key to our success.

How does flexibility play a role in the DOM industry and at Sharon Tube?

We have to be flexible enough to ensure that if a customer places a change or modification request to an order, they can count on the fact that we, as their supplier, will still be able to deliver the product on time. Our technology allows us to adapt when customers refine their needs. Whether it’s yield, tensile elongation, physical testing requirements, a shorter lead time, improved delivery requirements, increases to specific orders, changing a length, or additional testing, we do everything that we possibly can to make sure we’re saying “yes” instead of “no.”

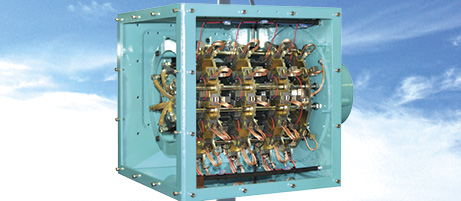

How does Sharon Tube’s new automated system increase service capability?

The state-of-the-art automation and tooling that we put in place allows for a consistency within our processes. We can do the same functions over and over again to ensure the correct quality within thousandths of an inch. We also have an integrated training system, providing hands-on qualified and dedicated employees that monitor and control the process. It’s easy to produce such a high-quality product.

What is your forecasting model and how does it allow for greater predictability?

We have a sophisticated forecasting model that takes a forecast received from our customer and drives those requirements through our supply chain back to the master coil raw material. This unique software solution enables us to offer more customization for our customers.

How have lead times in the industry changed over the years, and how have you adapted to them?

The DOM market is subject to swings in lead times. In the past two years, the market has experienced lead times ranging from four to 22 weeks. When lead times are extended, customers have to place orders well beyond their planning horizon. Our forecasting model allows us to permit change to their forecasts and deliver greater reliability and consistency as a result.

What is the operation process at Sharon Tube?

During the last two years, we’ve expanded our size range up to a nine-inch outside diameter, where we used to only go to six and a half. We’ve retooled our entire factory to increase our ability to move material through the mill very quickly. Our new high-capacity draw bench is among the largest in North America and has the capacity to pull three tubes in a single pass. We also have a new automated pickle and lube process that is timed to the second with advanced controls for consistent performance. Additionally, we have consolidated to one campus for our cold draw operations, which means everything (including our sales force, all the support staff, and the operations themselves) is located under one roof. This allows for a streamlined operation that results in faster turnover, as well as shortened lead times for our customers.

What does “quality” mean at Sharon Tube?

Quality is our first priority here at Sharon Tube. The employees care about their work, and they all want to put out a good product that not only meets but also exceeds ASTM and customer requirements. Customers know when our product comes through their door, they don’t have to worry – it will be exactly what they wanted.