Cylinder Speed Increases on a Forming Press

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

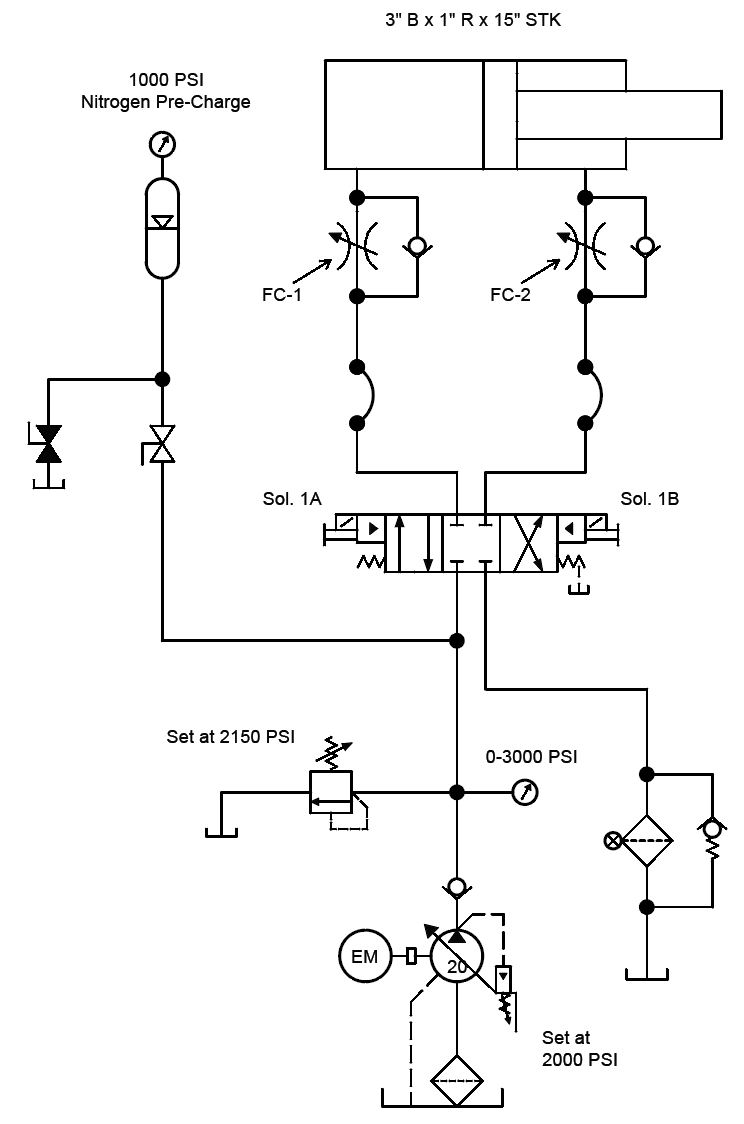

A forming press had a 3-inch cylinder that increased its extension speed even when no one adjusted the meter-out flow control on the cylinder’s rod side. The customer asked us to check the accumulator’s nitrogen precharge to see if it was low. They knew that lowering the precharge pressure resulted in storing more oil in the accumulator. So they thought the nitrogen gas was leaking off, and they did not have charging equipment with gauges to check it.

We told them they could check it by running the hydraulic pump until the system pressure reached 2,000 psi (138 bar), and then shut the pump down. We told them to slightly open the accumulator valve that dumps oil back to the tank and watch the gauge pressure as it slowly drops off. The pressure reading just before it suddenly drops to 0 psi would be awfully close to the gas precharge pressure. To their surprise, the pressure reading was close to the required 1,000 psi (69 bar).

The customer did not know what to do. Do you?

See the Solution

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com.

FC-1 is installed backwards.

Josh

The problem was a leaking piston on the cylinder. The circuit was working for years.