Duplex Filter Solutions for Power Generating Turbines

By Eric Rud, Global Hydraulic Filtration Product Manager, Eaton, Chanhassen, MN, USA

and Nima Hamzehzadeh, EMEA Hydraulic Filtration Sales Manager, Eaton, Filtration Division, Altlussheim, Germany.

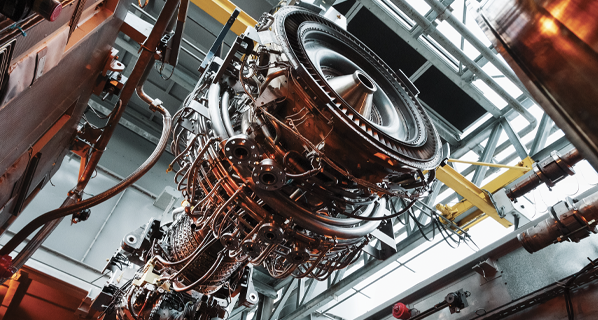

Hydraulic and lubricating oil contamination, be it abrasive solid particles or moisture, is the leading cause of shortened service life and reduced reliability in steam, gas and hydro turbines and turbo compressors. A cool, clean, consistent stream of oil is key to protecting bearings, shafts and other machine components at challenging temperatures and pressures. Likewise, continuous management of oil contamination is essential to maximize the potential of power generating turbines and to prevent unplanned shutdowns.

Poor oil quality caused by inadequate filtration costs the power generating industry millions of dollars a year in terms of lost production, spending for new oil and the added burden of unscheduled maintenance and repairs. To achieve optimal performance, it is important to consider the various aspects of hydraulic and lubricating oil filtration when operating and maintaining turbines and turbo compressors.

Poor filtration poses risks

Proper filtration removes water and particulates like dirt and scale that cause precision machine parts to wear down and can block cooling pathways, making turbines more vulnerable to overheating and the effects of vibration. Acids and corrosive compounds also can be deposited on metal surfaces causing permanent damage. Water and air meanwhile can enter through seals in turbine and extractor vents, potentially pulling moisture and debris into the system. Steam turbines can also have leaking gland seals or steam joints. Ultimately, contaminated oil compromises turbine efficiency and power output. In turn, performance suffers, and vibration and noise levels may increase as rotating components like bearings and shafts bear the brunt of the damage.

Oxidation stability, being the relative susceptibility of oil to degradation by oxidation, is the main determinant of hydraulic and lubricating oil usefulness in turbines. High temperatures and pressures, the presence of water and air, and contaminants of all types can greatly accelerate this process. Lubricating oils use inhibitors and antioxidants to combat oil breakdown; however, this balancing act requires a precisely tuned filtration solution to keep turbines and turbo compressors running smoothly.

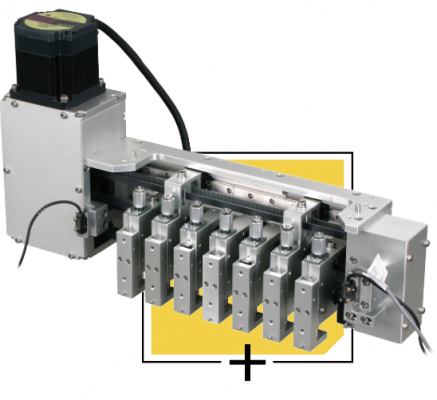

Duplex filter configurations can operate continuously. When a filter element changeout or service is required, filtration flow can be diverted from one side to the other. A pressure equalization system will ensure consistent pressure while the flow is being transferred.

Duplex filters provide strong defense

Simplex filtration is a system that uses one filter that usually requires frequent changing and maintenance to ensure the filter element is functioning properly and free of blockages. Conversely, most turbines and turbo compressors employ a duplex filter solution.

Under normal conditions, duplex filters operate continuously with minimal maintenance. Having two filter chambers connected by a changeover valve, a duplex filter is ideal where taking machines offline is impractical or disruptive, such as in the power generating industry.

Duplex configurations help turbine operators improve oil cleanliness and eliminate downtime due to filter element changeout. This design allows the process flow to be diverted to a secondary filter chamber so that one chamber is always in operation, thus eliminating the need to shut down the system as a clean chamber remains in standby mode at all times.

An effective duplex filter solution will have the following performance characteristics including:

Minimal pressure drop

The pressure loss at the filter should be as low as practically possible to maintain optimum system flow rate and pressure. A low pressure drop also means lower energy loss.

Flow capacity

The filter will be designed to adequately support the flow rate of the facility process.

Dirt-Holding Capacity (DHC)

The filter will be equipped with a sufficient amount of filter media to remove contaminants efficiently while maximizing the element’s useful life/extending change intervals.

Operating pressure

The filter will be designed to operate efficiently at system pressures which can be up to 6.3 MPa (914 psi), thus ensuring it remains intact during normal operations with minimal risk of bursting.

Bypass system

Optionally, the filter can be equipped with a system designed to allow oil to bypass the filter if the element becomes clogged, thus preventing the element from collapsing. Filter bypass systems are generally not applied to contamination-sensitive lubrication systems.

Quality components

Switchover valves require high-integrity design and material construction to prevent leaks that could potentially pose fire hazards.

Building a complete filtration system

There are additional considerations that turbine and turbo compressor operators must be aware of. Besides low-pressure duplex filtration, a complete hydraulic system, whether for the lubrication system or auxiliary systems, requires additional oil conditioning solutions including:

Solutions for effective protection of components.

Turbine control and auxiliary hydraulic systems require continuous filtration to protect equipment and components. For lubrications systems the market offers standard and custom-built duplex filter solutions to meet different requirements for connection size (commonly 3″/DN80 to 8″/DN200) and operating pressure from 1.6 to 6.3 MPA (232 to 914 psi). In addition, common auxiliary systems can use duplex or simplex high-pressure filters with pressure requirements up to 41.4 MPa (6,000 psi). All applications must be designed to allow a sufficient margin of safety for pressure peaks in the system to be absorbed.

Solutions for oil service.

Additional offline filtration of lubricating oil is recommended for power generating turbines and turbo compressors. These units tend to use a side-stream return line to remove solid particles and some free and emulsified water from the oil. Offline filtration goes further to reduce oil aging and in turn spending for new oil or worse—bearing and shaft repairs. Offline filtration units have been developed for all viscosity ranges, from transformer to heavy gear oils.

In all types of power plants, filtration products help to ensure a reliable supply of clean, cool hydraulic and lubricating oil. These solutions (from left to right) typically include mobile filter units, oil purifier systems, clogging indicators and offline filter elements having water absorption layers.

Solutions for the effective removal of free water.

Water is a particularly destructive foreign substance in hydraulic and lubricating oil systems. Duplex filtration solutions may also employ automated purifiers to effectively remove free emulsified and dissolved water, free and dissolved gases, and particulate contamination down to 3 microns. These water removal devices are also known as vacuum dehydrators and can be added to online or offline oil systems or reservoirs.

Solutions for continuous contamination control.

Reliable indication of when to change the filter element can be important. As the filter element becomes clogged the differential pressure increases. A clogging indicator monitors the differential pressure and alerts operators when a replacement filter element is needed. Indicators should be of rugged quality and electric-explosion-proof, having multiple set points (e.g., 70% and 100% clogged) to accommodate different system requirements.

Solutions for oil conductivity.

Electrostatic discharge is common with zinc-free hydraulic and lubricating oils that do not contain the heavy metals of the previous generation of fluids. With the increasing use of synthetics in oils to replace zinc additives, oil conductivity is lowered. In turn, static charges can be generated as oil flows through the filter, causing sparks to propagate from the filter media to the filter’s metal supports. Including the risk of explosions, this can degrade the oil and create varnish, which can cause valve spools to seize up, solenoids to overheat and filters to clog.

This discharge can further damage the filter and possibly interrupt electrical systems. For oils with a conductivity below 300 pS/m (picosiemens per meter, a measure of a fluid’s electrostatic chargeability), it is recommended to use high surface area filters with anti-static elements that are designed to provide optimum filtering efficiency while reducing electrostatic discharge.

The benefits are many, including increased machine and operator safety, protection for sensitive electronic systems, low pressure drop, high dirt-holding capacity and long filter life.

Solutions for industry compliance.

Duplex filtration products and solutions may need to be designed to applicable EN 13445 (Unfired Pressure Vessels), AD 2000 (per the German Pressure Vessel Association) and ASME Sec. VIII, Div. 1 (Rules for Construction of Pressure Vessels) standards, as well as meet Pressure Equipment Directive (PED) requirements including CE Marking where necessary. Eaton can meet the stringent design, manufacturing and testing standards that govern the supply of hydraulic filtration products to the power generating industry. Solutions and components of indefinite origin should never be considered—all products must conform to major industry certifications.

Poorly maintained turbine hydraulic and lubricating oil costs the power generating industry millions of dollars in lost production each year.

Seek expert design assistance

Eaton’s Filtration Division can help turbine and turbo compressor operators determine a specification for their hydraulic and lubricating oil that considers the fluid’s particulate and water removal requirements. Typically, these specifications are based on SAE (Society of Automotive Engineers), AGMA (American Gear Manufacturers Association) or ISO (International Organization for Standardization) classifications.

The need for oil cleanliness has changed over the past 20 years. Driven in part by demands from bearing manufacturers for improved oil purity and also due to environmental concerns, requirements for filter fineness have grown more stringent as the working relationships between bearing and turbine manufacturers deepen. OEM recommendations for some oil cleanliness levels are as high as 16/14/11 per ISO Cleanliness Code requirements where 16 means there are 200 to 640 particles per ml greater than 4 microns in size, 14 indicates 80 to 160 particles greater than 6 microns, and 11 indicates 10 to 20 particles greater than 14 microns.

Experts can also help to ensure the most efficient filtration process by recommending a regular maintenance schedule, one that includes steps to identify leaks and blockages. Additionally, a specialist can assess any changes in the operating process, such as using a new filter media type, and adjust the filtration strategy accordingly to maintain oils to target cleanliness levels and with minimal water content.

When oil cleanliness is a problem, often the solution is to design a single filter with a pump and motor to move the oil; however, this tends to overlook the value a new or upgraded duplex filter solution can bring. Taking steps to ensure oil cleanliness is equally important for alternative power generating sources such as wind turbines and hydrogen compressors. Reliable filtration will help various wind, solar and hydro power sources reach their full operating potential in the years ahead. While system sizing and operating pressure requirements may change, the fundamentals of effective oil filtration remain the same for power generating equipment of all types. There also exists a balance between filter fineness and system performance that can be hard to achieve—hydraulic filtration experts can help companies achieve this balance and avoid costly mistakes and miscalculations.

Oil filtration is a critical component of reliable turbine and turbo compressor performance. Proper selection and installation of a duplex filter solution, including regular maintenance of the system, are essential for optimal performance and to prevent downtime and repairs caused by poor oil quality. A hydraulic filtration specialist can help turbine owners ensure smoother operations day in and day out by keeping hydraulic and lubricating oils clean.