Electric Motor Blowing Overloads

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

We were called out to trouble shoot a problem on a heat-treating system’s hydraulic unit in which the electric motor was reading twice the nameplate amperage and causing the overloads to fail. The customer had the motor checked out by a reliable motor-repair house and they felt the problem was with the hydraulic system.

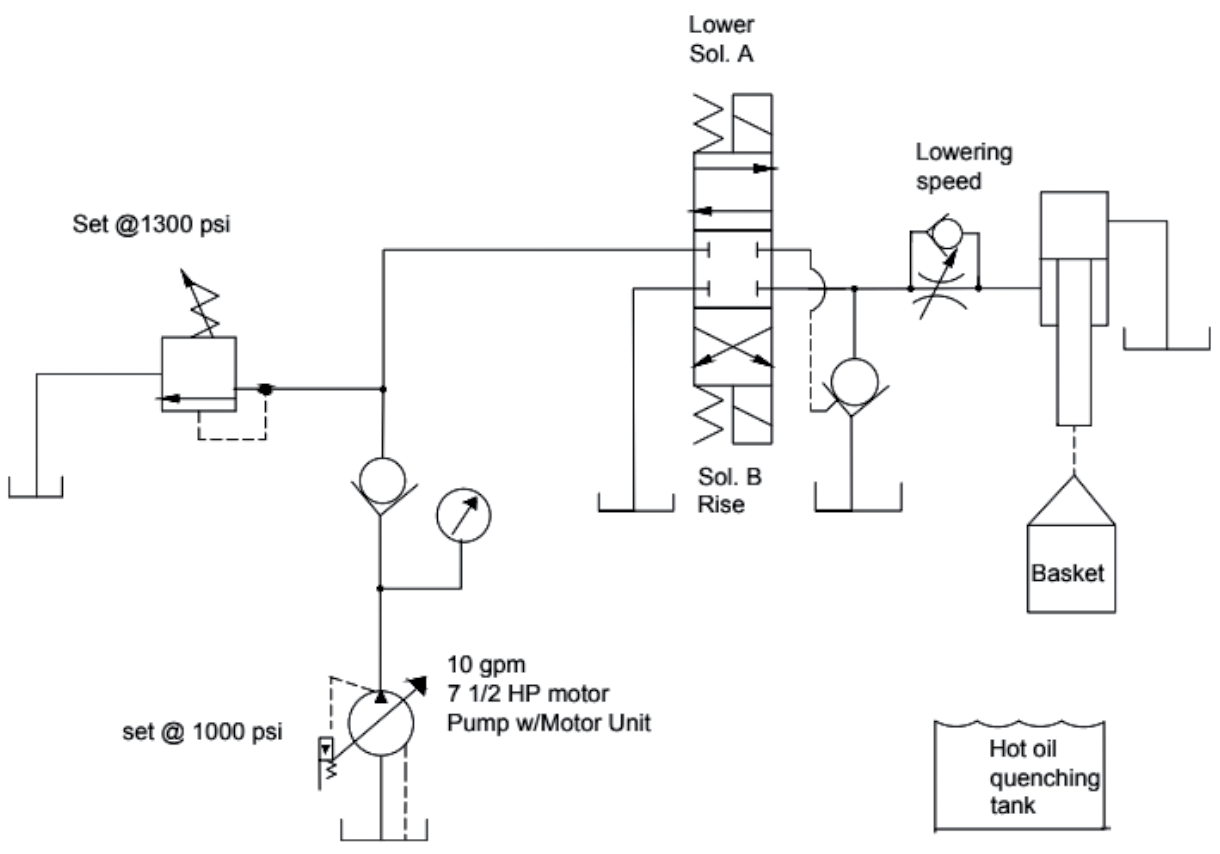

The system had an overhead vertically mounted cylinder with the rod end attached to a large basket. The rod would extend lowering the basket into the hot quenching fluid, where it would sit for hours and then would be raised to the unloading position by retracting the cylinder.

When we arrived, we found the that the overload problem would happen every so often when the cylinder was lowered by the weight of the basket pulling on the rod. When the machine would cycle normally, our amp meter never exceeded the maximum nameplate amp rating of 20 amp, but when the problem popped up, the amps would exceed 108 inrush and drop to 40 amps and trip the overloads all within 1 to 2 seconds. We could not find any mechanical malfunctions, so it had to be a hydraulic problem.

Any idea what the problem turned out to be?

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com.

The basket could occasionally be overloaded. By design, if anything in the circuit exceeds the pump pressure, the pump outlet check should close and the pump would de-stroke. 10gpm at 1000psi should be around 6.7hp to the motor. So everything normal, it should be fine.

Pump line check failure could back-feed the pump with flow with a basket causing a higher than normal pressure, during a raise cycle.

Pump could be set incorrectly high and be common to the the system relief flow if it cracks due to excessive basket weight.

I’d go with my first answer first to troubleshoot. If anything in the system exceeds the pump set-point, that check should close and the pump/motor should be fine.

the problem was posted in 2020, so this customer is probably pretty upset at this point that nobody has fixed his issue!