Electronic Controls Specialist (ECS)

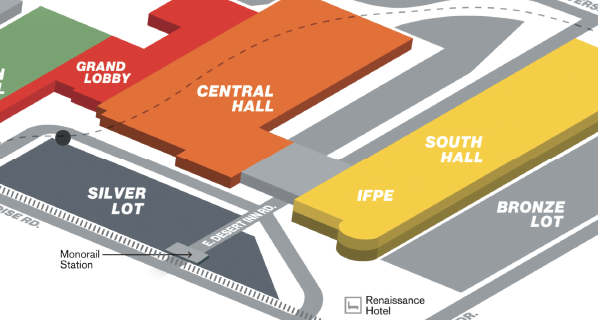

If you currently hold an IFPS Hydraulic Specialist, Pneumatic Specialist and/or Specialist certification, the ECS is a perfect complementary certification for you to obtain.

If you currently hold an IFPS Hydraulic Specialist, Pneumatic Specialist and/or Specialist certification, the ECS is a perfect complementary certification for you to obtain.

Our newly revised study manual not only helps you prepare for the certification, but it is also a stand-alone reference guide. It contains vital and practical information on best practices for anyone responsible for designing, analyzing, or selecting components for the electronic control of fluid power systems.

Certification Outline

Job Responsibility

Fluid Power Systems

- Read and interpret fluid power schematics

- Perform calculations that describe the motion and force of fluid power actuators

- Demonstrate an understanding of friction and leakage in fluid power components and their effects on system performance

- Identify the causes and minimize the effects of hydraulic shock in a system

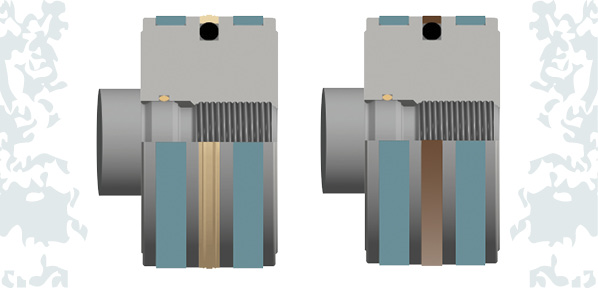

- Demonstrate knowledge of the operation and application of proportional valves

- Describe the operation and application of electric flow control devices

- Describe the operation and application of electric pressure control devices

- Demonstrate a knowledge of the effects of pressure-compensated components on control systems

- Demonstrate knowledge of the operation and the application of servo valves

- Demonstrate knowledge of the effects of mechanical nulling on control systems

Job Responsibility

Electronic and Electrical Principles

- Basic Electrical Quantities and Measurements

- Inductance/Capacitance

- Block Diagrams

- Power Supply

- Circuit Protection

- NEC Wiring Considerations

- Power and Signal Quality

- Grounding

Job Responsibility

Input/Output Devices

- Switches

- Input Potentiometers and Joysticks

- Sensors

- Application of Sensors

- Sensor Sinking, Sourcing and Wiring

- Understanding Encoders, Linear Sensors, and Transducers and Joysticks

- Solenoids

- Operating Environmental Considerations

Job Responsibility

Applying Control Theory

- Determine Hydraulic Stiffness of a System

- Determine Actuator Natural Frequency

- Describe Frequency Response of a System

- Interpret Bode Diagrams

- Identify General Control System Design

- Understand Control Techniques Used in Fluid Power Systems

- Interpret and Create Block Diagram

- Evaluate Basic System Physics

- Discuss the Effect of PID Loop Tuning on a Fluid Power System

Job Responsibility

Interacting with Controllers

- Select Controller Architecture

- Specify Controller Performance Parameters

- Select Controller Interface Hardware

- Understand IEC 61131-3 Logic Programming

- Recognize Common Program Solutions

- Trace and Influence Data

Job Responsibility

Utilize Industrial Networks

- Open System Interconnect Model

- Select Network Architecture and Components

- Network Implementation Considerations

- Wireless Networking in Fluid Power

- Human Machine Interfacing

Visit www.ifps.org/specialist to learn more and to test your skills with online pretest questions.