Emerson Expands Condition Monitoring Software

Emerson is updating its machinery health platform to enable customers to migrate to a more holistic, modern interface for condition monitoring.

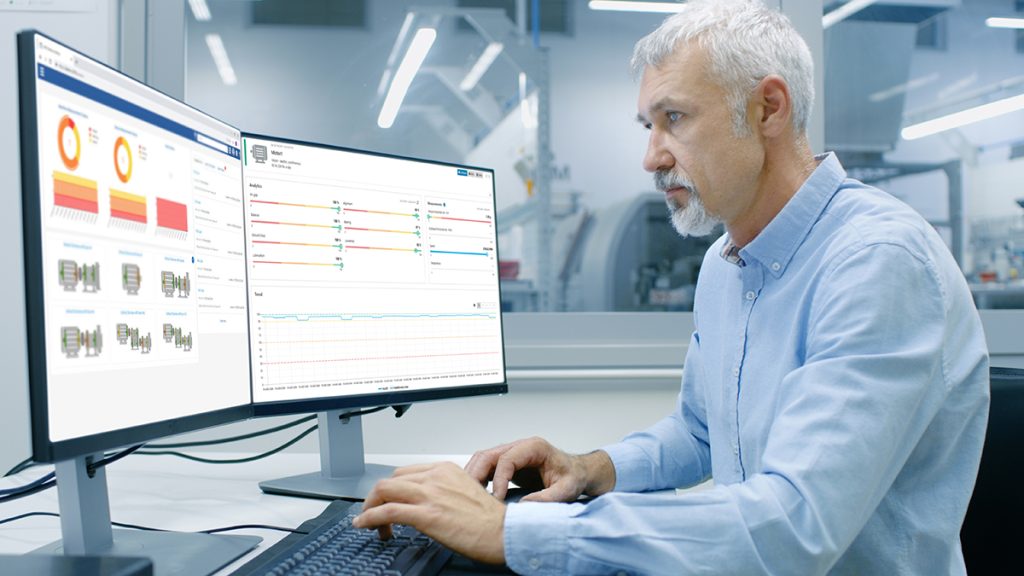

To help small teams make the most of limited resources, Emerson has continuously evolved AMS Machine Works’ condition monitoring technologies for better diagnostics at the industrial edge. Increased connectivity to external systems provides personnel with an intuitive, holistic asset health score supported by maintenance recommendations to help reliability teams quickly see what is wrong and how to fix it. Intuitive information and alerts are delivered directly to workstations or mobile devices to provide decision support, helping maintenance personnel make the best use of their time.

The newest version of AMS Machine Works adds support for Emerson’s AMS Asset Monitor, which provides embedded, automatic analytics at the edge using patented PeakVue technology to alert personnel to the most common faults associated with a wide range of assets. AMS Machine Works also supports open connectivity using the OPC UA protocol to make it easier to connect to external systems such as historians, computerized maintenance management systems, and more to help close the loop on plant support from identification to repair and documentation.

For more information, visit www.emerson.com/conditionmonitoring.