Hydraulic Solutions for Blueberry Production

The United States, along with the rest of the world, is trying to eat healthier. In our search for tasty food with lower calories, we have helped create a boom in the blueberry industry. Blueberries only have about 80 calories in a one-cup serving and no fat!

According to Albert Wildes, past president of the Georgia Blueberry Growers Association, the current acreage of blueberries is approximately 29,000. That is a 200% increase over the past few years, and Georgia is not alone. Other states that grow blueberries include Michigan, New Jersey, Florida, North Carolina, Oregon, and Washington. There are small acres in Mississippi, Texas, and Alabama. Georgia, however, has the longest harvest, ranging from late April to July.

With the increased acreage in blueberries, there is now a great need for equipment to maintain the blueberry fields and harvest the blueberries. Blueberries grow on bushes, and keeping the bushes healthy and picking the berries at the peak of freshness will give the grower the largest profit from his blueberry fields.

With the increased acreage in blueberries, there is now a great need for equipment to maintain the blueberry fields and harvest the blueberries. Blueberries grow on bushes, and keeping the bushes healthy and picking the berries at the peak of freshness will give the grower the largest profit from his blueberry fields.

Getting in the way of a profitable harvest are spotted winged drosophilas (SWD) and other common pests. These insects do their best to eat the berries before they can make their way to our kitchens. There are pesticides that will protect the berries, but they must be sprayed frequently and are affected by rainfall, requiring another application if nature washes off the first one.

For all blueberry lovers and growers, Bennett’s Tractor Service in Waycross, Ga., has designed a piece of equipment that does double duty. Not only is this sprayer designed specifically for blueberries, but it is also a hedger that allows the growers to groom their fields, making harvesting more productive. Other sprayers are available, but they are not specific to blueberry rows and they are designed for just a single purpose: spraying (Fig. 1).

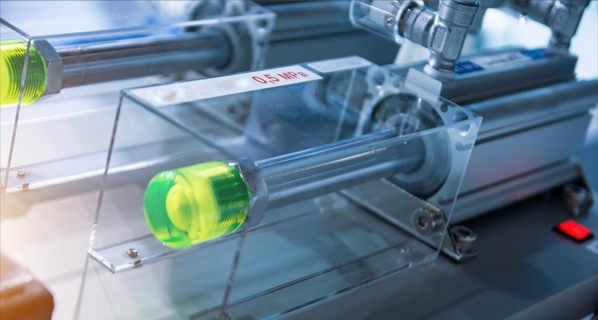

Cross Company has helped Bennett’s Tractor with a hydraulic transmission utilizing Poclain wheel drive motors and pump. The hedger/sprayer has two drive modes: a travel mode that can attain over 17 mph and a work mode that gives us more torque while traveling at speeds of 5 mph and slower in the field. Cross Company has also supplied the filtration, oil cooler, electrically operated hydraulic valves, auxiliary pumps, and LSHT motors to operate the hedger blades (Fig. 2).

The Bennett’s Tractor hedger/sprayer can get to the fields quickly to apply pesticides or fertilizer. During the growing season, this might need to be applied weekly or whenever rainfall has washed away the last application. Once the growing season is over, the hedger will groom the plants and get them ready for the next growing season. The hedger is adjustable from 32″ to 6′-wide hedgerows.

The Bennett’s Tractor hedger/sprayer can get to the fields quickly to apply pesticides or fertilizer. During the growing season, this might need to be applied weekly or whenever rainfall has washed away the last application. Once the growing season is over, the hedger will groom the plants and get them ready for the next growing season. The hedger is adjustable from 32″ to 6′-wide hedgerows.

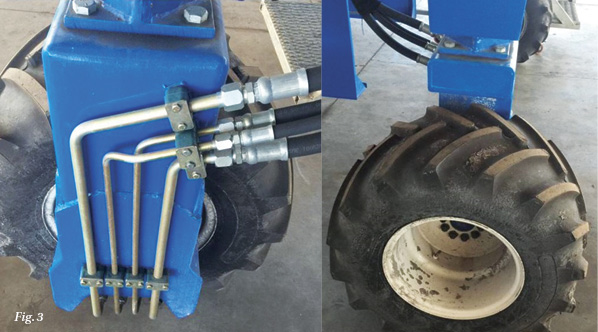

The hydrostatic transmission was selected as the most efficient way to transmit power to propel the tractor. Poclain Hydraulics engineered custom two-speed motors, which maximize torque and speed. Poclain also provided solenoid valves for speed selection and brake control (Fig. 3).

A simple bank of switches in the air-conditioned cab allows the operator to control the various functions of the hedger/sprayer. The sprayer wings fold up to allow the hedger sprayer to be hauled on a trailer or travel from field to field with a much smaller footprint. Eaton steering controls take care of turning and tracking.

For the foreseeable future, we can expect blueberry production to trend upward. Hydraulics will be at the forefront of planting, growing, and harvesting the blueberries that we add to our breakfast cereal, yogurt, and tasty pie, helping to increase profits for growers and deliver a quality product for consumers.