Intensifier Drops from Required Pressure after Several Hours

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

We were called in to look at a filter press that, when closed, needed to hold 8,500 psi (586 bar) for several hours. Used in various industries, a filter press separates liquids and solids using pressure filtration. A slurry is pumped into the filter press and dewatered under pressure. The press can be used for wastewater treatment in a variety of different industries and applications. Basically, the press is used to squeeze water out of the product waste with pressures as high as 10,000 psi (690 bar).

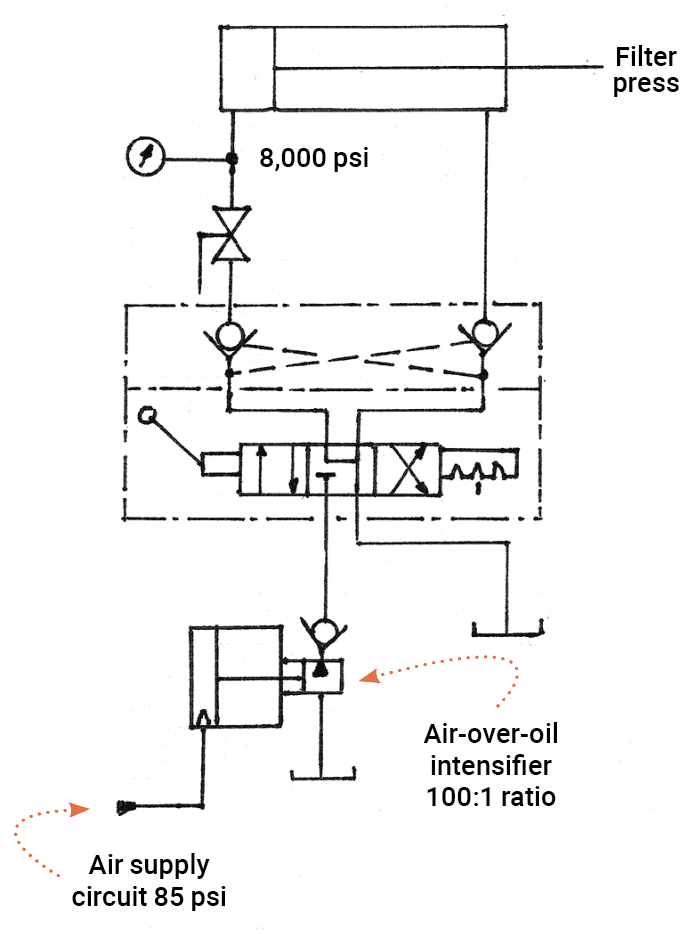

They did not have a circuit on this machine, which was 25 years old, so the sketch on the left is what I felt the circuit to be.

They described the normal cycle as follows:

- They would shift the 4-way directional valve to close the press.

- Pressure was applied using an air-over-oil intensifier to build the pressure up to 8,500 psi (586 bar).

- After 8 to 10 hours, the filter media would be fully loaded with a cake-like waste material.

- They would shift the directional valve to open the press and unload the caked filter media.

- The air-over-oil unit would hold for 1 to 2 minutes before resetting, (the piston would retract), and cycle once again.

The problem they were having was that the pressure applied would hold at 8,500 psi (586 bar), but after 2 to 3 hours, it would start dropping down to 5,000 psi (345 bar) in less than an hour and hold there with the air/oil intensifier cycling constantly. The side of the directional valve stack that included the pilot-operated check module was hot to the touch. Nothing else showed any hot spots. If the ball valve on the back of the cylinder was closed, the 8,500 psi (586 bar) would start very slowly to decay and reach the 5,000 psi (345 bar) reading after 3 to 4 hours with the intensifier turned off. The cylinder had a small leak path across the cylinder piston.

What is the solution?

See the Solution

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com.

With all the info given in this troubleshoot, and based on the last observation that “The cylinder had a small leak path across the cylinder piston,” I would recommend repairing or replacing the Cylinder, as well, inspect/clean or replace the Pilot-operated Check Valve.

Thanks for your time.