New Problem: Ram Falls on a New Installation

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

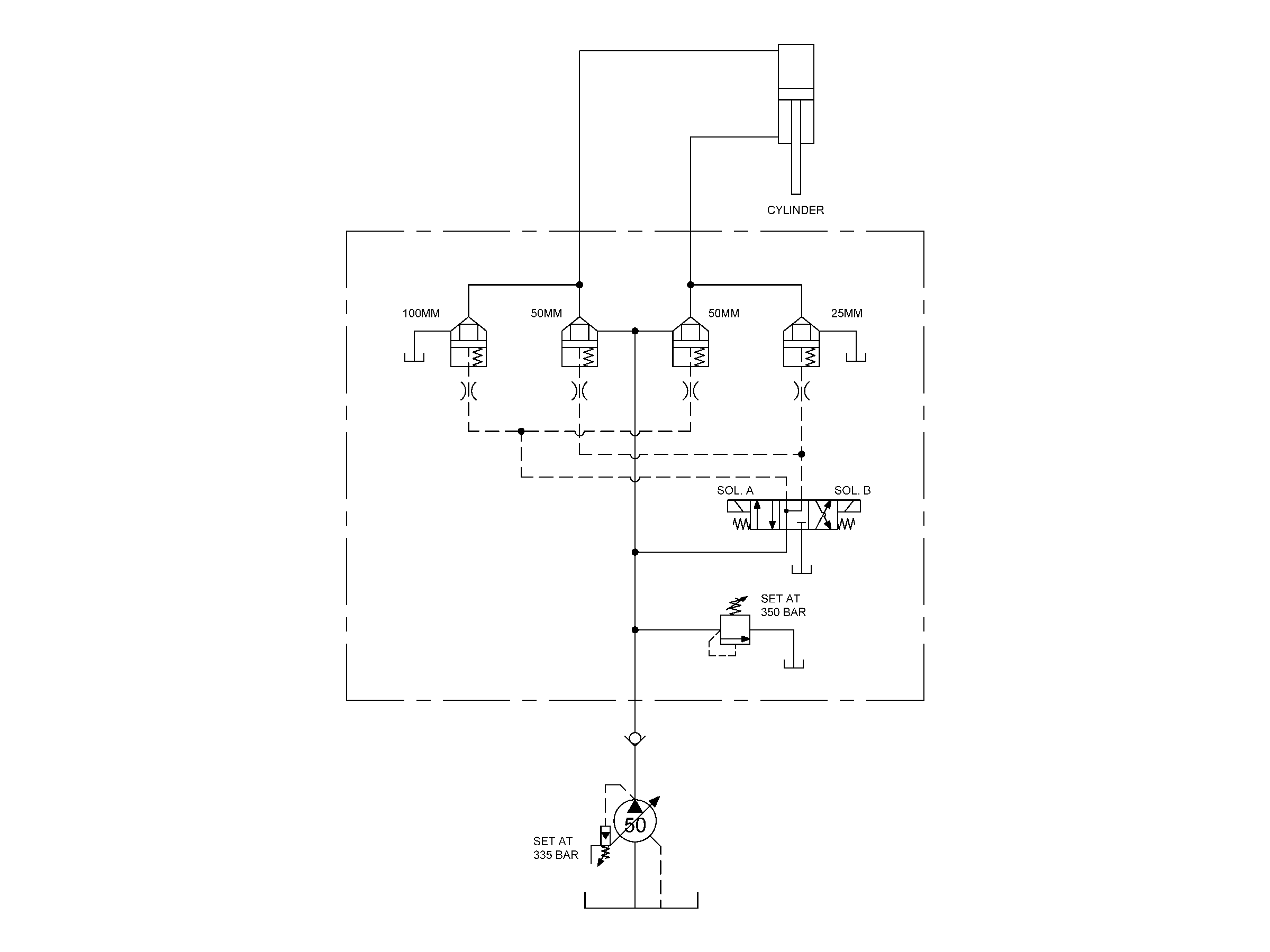

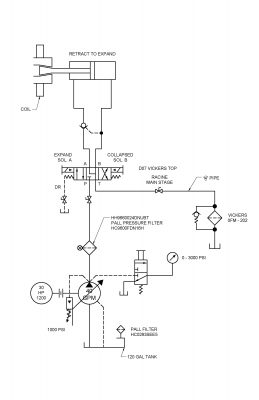

A new press was installed in a factory that makes steel bumpers for over-the-road tractors. The hydraulic power unit was supplied by a local hydraulic distributor that would only control the main ram supplied by the press manufacturer. The factory had a central system that would control all the auxiliary actuators on the press.

When everything was assembled on the plant floor and commissioning was started, they found that the main ram would not stay up in the neutral position. No matter what position the ram was stopped, it would fall to the fully extended position. They also lost pump pressure.

The power unit builder assured the customer that they tested the unit with one of their cylinders laying on their shop floor and it functioned well, extending and retracting as designed.

Any idea why the ram falls in the neutral position?

“Ram Falls on a New Installation”

Greetings Mr. Sheaf,

Did the service tech install any gauges; cylinder rod and cap end for example?

I presume the head is quite heavy, but what does it weigh? A gauge in the rod end of the cylinder would quickly confirm the head load.

“The ram falls”, I think of “fall”, as slamming to the floor; drifting down, slow, but noticeable; creeping down, takes a long time and may not be noticed. It’s a little clearer when the symptom is more defined and certainly helps with troubleshooting. There’s no such thing as too much information.

The design lacks simple servicing and troubleshooting features like 1/4 turn valves to isolate the ram. My hunch is that if there was a 1/4 turn valve on the rod end of the ram one would find that the ram is leaking internally and of course would drift down unless there’s something really bad with it where so much fluid is leaking that it can’t develop sufficient pressure to support the mass of the head and of course fall.

I always find these troubleshooting problems challenging and entertaining. But I have to stress using good practice and part of that is good communication of the symptoms, asking the right questions and using the tools needed to measure what’s going on in the circuit.

Appears that the DCV is using a regen center and should be a float center

With regen center standby pump pressure would keep the CBV open so the cylinders would

bleed down with valve centered.