Pressure & Vacuum in Print

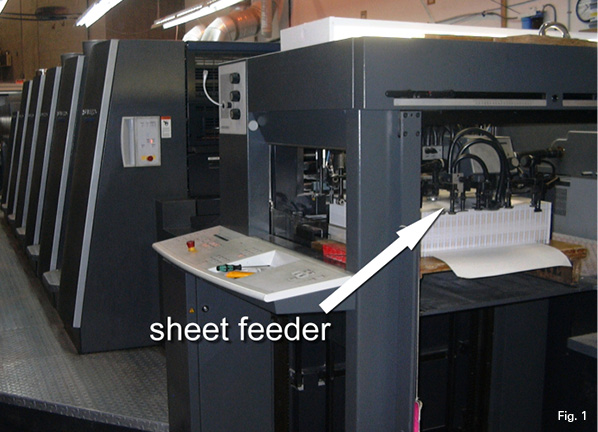

In the printing industry, vacuum and low-pressure air is used extensively in the sheet feeding heads of web offset printing presses (Fig. 1). These presses utilize vacuum throughout the machine to transfer sheets of plain paper from one end to the finished printed paper at the other. Common printing projects are large quantity runs of catalogue pages, brochures, posters, and other color or grayscale material.

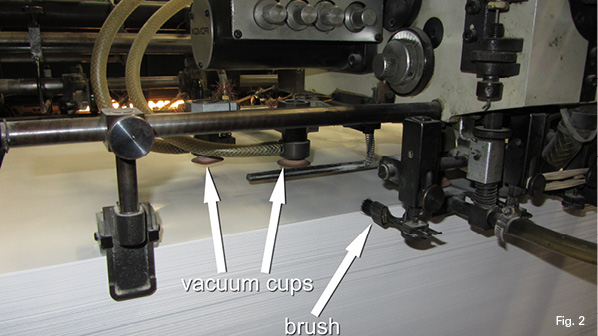

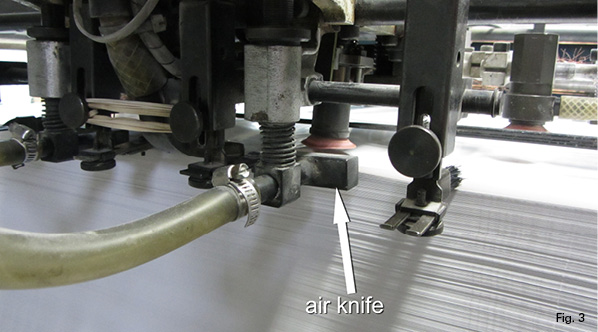

Plain sheets of paper are placed at the front of the press. The sheet is lifted and “dragged” into a mechanical conveyor with vacuum cups (Fig. 2). The vacuum cups lift the top sheet while a static brush head helps to prevent the sheets underneath from being lifted, as well. Low-pressure air blows into the side of the sheet to aid sheet separation (Fig. 3).

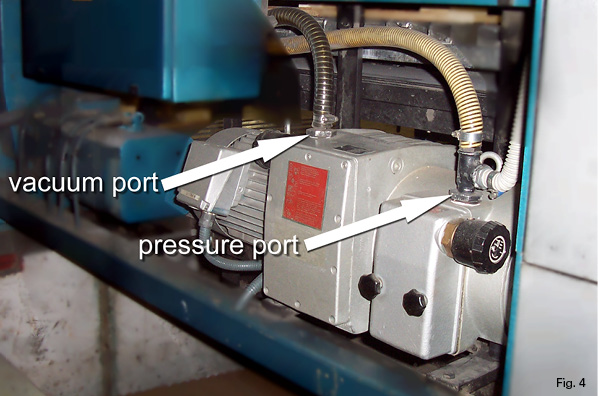

The vacuum and low-pressure air is often generated by what is referred to as a “pressure-vacuum” pump as shown connected to a press (Fig. 4). This pump, which looks similar to a standard sliding vane vacuum pump, generates both vacuum and low pressure, pulsation-free air, at the same time. The vacuum port is connected to the vacuum cup line(s), whereas the exhaust port of the pump is connected to the low-pressure air lines. This type of pump offers the advantage of a single pump producing both vacuum and air for the sheet feeder and is a very easy solution for this task.

However, the pump is quite large with typical models that generate >10 cfm weighing in excess 50 lbs. Therefore, these pumps should be mounted either on the floor or in a frame on the side of the machine. Consequently the distance from the actual vacuum cups and air knives could be considerable.

As a result, these pumps are often oversized to compensate for this distance. The vacuum levels being generated are lower than standard sliding vane pumps as the exhaust is being restricted by the low-pressure air application. Maximum vacuum is usually about 18″Hg at the pump. As is typical with printing presses, the installation of the vacuum lines is complicated with many joints and flow restrictions, and therefore by the time vacuum is seen at the vacuum cups, the vacuum level has dropped considerably. Of course the vacuum cups do not require a high vacuum level so this technology does work well, but consideration should be made to alternatives to traditional pressure-vacuum pumps if the opportunity arises for the user.

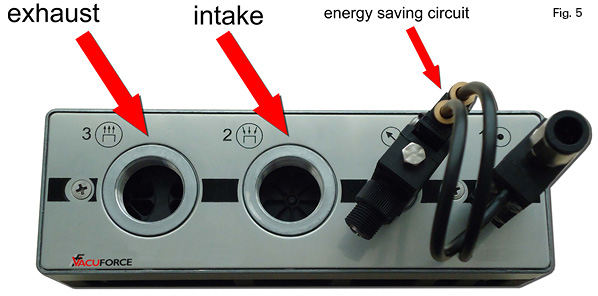

Because these pumps run continuously, the maintenance requirements are frequent. This normally consists of basic maintenance, which in this case is a vane kit replacement, but this can be very costly over a 12-month period and sometimes require a technician outside of the facility to undertake this task. An alternative to the pressure vacuum pump could be an air-powered vacuum generator (Fig. 5). These multistage generators offer adjustable vacuum levels depending on the compressed air inlet pressure, and being very compact and lightweight, they can be placed much closer to the point of use—the vacuum cups.

If used properly, the air-powered vacuum generator (venturi) can use the same amount of energy and in most cases, much less. As the inlet pressure is fully adjustable, the user can use the minimum compressed air pressure, which in turn will minimize the compressed air consumption.

A sheet feeder usually consists of only four to eight 1″ diameter (25 mm) cups (depending on the size and weight of the paper being printed), and therefore the vacuum generator does not need to be large. A typical generator for this application would only require about 4 cfm of compressed air to operate. This equates to about 1 hp of compressor power. The same type of vacuum generator can be used for the low-pressure air as well, simply by connecting the low-pressure airlines to the exhaust of the unit (Fig 5). In this case a vacuum filter is placed on the inlet to prevent impurities from contaminating the venturi. The principle of a multi-stage generator is to create more vacuum flow than single-stage models per unit of compressed air consumed. A typical multi-stage vacuum generator that uses 4 cfm of compressed air will actually amplify the exhaust by about 4:1. Therefore >16 cfm will be provided at the exhaust—ideal for sheet separation. The other benefit of air-powered vacuum generators is that, if filtered properly, they will provide virtually maintenance-free ownership.

The generator shown in Fig. 5 also utilizes an “energy saving” kit. This will turn off the compressed air automatically to the generator if the vacuum level reaches a preset point. Therefore, when the press stops, the vacuum level will rise and the compressed air is turned off, turning on again as soon as the press restarts. More often than not, vacuum pumps with electrical motors keep running if the press is in a standby state, regardless of whether or not the press is being used for actual printing.

Sheet feed web offset presses are often supplied to customers with the pumps included, which offers a complete turnkey “ready to go” press. Smaller printing shops often do not have the necessary compressed air available to operate the vacuum generators. However, in larger facilities with centralized compressed air systems, vacuum generators could offer a very viable and efficient alternative to the pressure-vacuum pump.

This article is intended as a general guide and as with any industrial application involving machinery choice, independent professional advice should be sought to ensure correct selection and installation.

I wanted to know please , does these vacuum clips stops from vacuuming the paper if its size rising than that the user specified the vacuum on . And if that happened what is the solution for that stopping if I wanted it to continue whenever that happened .