Automation in Manufacturing: Vacuum Pick & Place Technology

By Daniel Pascoe, President, Davasol Inc.

In today’s fast-paced manufacturing landscape, the pursuit of efficiency, precision, and automation is unrelenting. A transformative force in this relentless pursuit is vacuum pick and place technology. This technology has not only revolutionized how industries handle materials and components but has also elevated productivity, enhanced precision, and drastically reduced manual labour, handling inaccuracies particularly regarding preventing damage to the product being handled. In this article, we will delve into the multifaceted world of vacuum pick and place technology. We’ll explore the intricate array of vacuum cups, their diverse applications across industries, the myriad benefits they bring to manufacturing, and the promising future they usher in.

To appreciate the significance of vacuum pick and place technology today, it’s essential to understand its evolutionary journey. The roots of this technology can be traced back to the mid-20th century, where it emerged as a solution to the increasing demands for automation in manufacturing.

Early vacuum pick and place systems were rudimentary, employing basic suction cups to manipulate relatively simple objects. However, over the decades, advancements in materials science, robotics, and sensor technology have propelled this technology to new heights. Today, vacuum pick and place systems employ an impressive variety of specialized vacuum cups and vacuum generation devices, each designed for specific applications and processes.

Types of Vacuum Cups

Vacuum cups form the heart of vacuum pick and place systems, and their diversity is a testament to the technology’s adaptability. Let’s explore the primary types of vacuum cups used in these systems in greater detail:

Flat Suction Cups: The traditional workhorses of vacuum pick and place technology, are typically made from materials such as silicone or nitrile rubber (NBR). They excel at handling smooth, non-porous objects like glass, ceramic, and select plastics. The versatility of flat suction cups is underscored by their ability to come in various shapes and sizes, tailored to accommodate objects of varying dimensions, however they are limited to rigid flat or only slightly concave or convex surfaces.

Flat Suction Cups: The traditional workhorses of vacuum pick and place technology, are typically made from materials such as silicone or nitrile rubber (NBR). They excel at handling smooth, non-porous objects like glass, ceramic, and select plastics. The versatility of flat suction cups is underscored by their ability to come in various shapes and sizes, tailored to accommodate objects of varying dimensions, however they are limited to rigid flat or only slightly concave or convex surfaces.

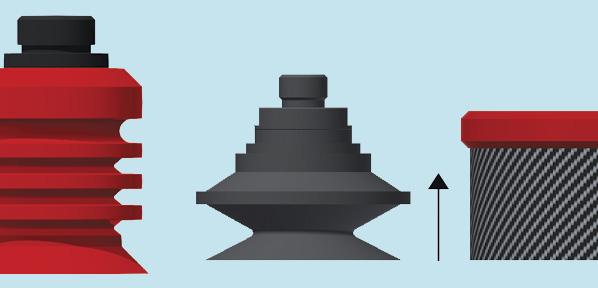

Bellows Cups: Bellows cups are engineered with a bellows-like structure that grants them the unique ability to conform to irregularly shaped or porous objects. This adaptability is invaluable when dealing with objects of varying heights, curved surfaces, or those with intricate contours. Bellows cups find frequent use in industries like packaging, logistics, and automotive manufacturing. More often than not they are also the go to choice due to their ability to compensate for varying changes in the product face datum.

Bellows Cups: Bellows cups are engineered with a bellows-like structure that grants them the unique ability to conform to irregularly shaped or porous objects. This adaptability is invaluable when dealing with objects of varying heights, curved surfaces, or those with intricate contours. Bellows cups find frequent use in industries like packaging, logistics, and automotive manufacturing. More often than not they are also the go to choice due to their ability to compensate for varying changes in the product face datum.

Foam Vacuum Pads: Foam pads are a specialized type of vacuum cup being used where traditional rubber vacuum cups are not able to grip the loads being handled. Typically made from a closed cell neoprene or natural rubber, these cups conform to the shape of the object creating a vacuum seal. Often found in applications involving rough sawn wood, pallet handling, stone and bring palletising.

Foam Vacuum Pads: Foam pads are a specialized type of vacuum cup being used where traditional rubber vacuum cups are not able to grip the loads being handled. Typically made from a closed cell neoprene or natural rubber, these cups conform to the shape of the object creating a vacuum seal. Often found in applications involving rough sawn wood, pallet handling, stone and bring palletising.

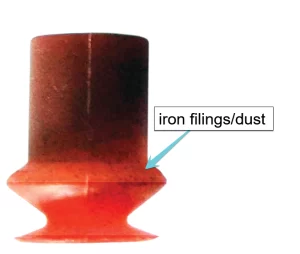

Metal Detectable Cups: These vacuum caps are made from a metal detectable silicon material. Comprising of a fine iron dust within the compound they can be detected by metal detectors in the production process. This prevents product safety recalls where vacuum cups may become unattached from their machine fittings and fall into the product packaging. The news article you read from time to time referring to rubber or plastic “contaminants” are often suction cups that came loose in the packaging line.

Metal Detectable Cups: These vacuum caps are made from a metal detectable silicon material. Comprising of a fine iron dust within the compound they can be detected by metal detectors in the production process. This prevents product safety recalls where vacuum cups may become unattached from their machine fittings and fall into the product packaging. The news article you read from time to time referring to rubber or plastic “contaminants” are often suction cups that came loose in the packaging line.

Applications of Vacuum Pick and Place Technology

The applicability of vacuum pick and place technology spans a spectrum of industries, each harnessing its unique capabilities to optimize processes and outcomes. Here are some key applications:

Electronics Manufacturing: In the electronics industry, the precision of vacuum pick and place systems is paramount. Suction cups excel at handling delicate components like microchips and semiconductor wafers. Conductive silicone is designed to dissipate static electricity efficiently. In electronic manufacturing environments, static electricity poses a significant risk to sensitive electronic components. When static discharge occurs, it can damage or destroy microchips, transistors, and other delicate parts. Conductive silicone suction cups help prevent the buildup of static charges by providing a low-resistance path for the electrical charge to dissipate harmlessly. This safeguard protects electronic components from electrostatic discharge (ESD) damage during the pick and place process.

Pharmaceuticals: Vacuum pick and place systems equipped with suction cups are indispensable in pharmaceutical manufacturing. They adeptly handle vials, syringes, and medication blister packs. Using FDA (U.S. Food and Drug Administration) compliant silicone suction cups in the pharmaceutical industry is not only a matter of regulatory compliance but also a crucial step in ensuring product safety, quality, and overall process efficiency.

Food Processing: In the food industry, vacuum pick and place technology enhances both efficiency and hygiene. Suction cups find use in packaging applications, where they assist in the precise placement of food products into containers. Multiple bellows cups are employed for direct food contact as well as plastic wrapped finished product. Just like the pharmaceutical industry, FDA compliant silicone is required for direct food contact applications and certainly recommended.

Automotive: The automotive manufacturing sector benefits immensely from vacuum pick and place technology. This technology’s versatility is evident as it seamlessly handles various components, from facia panel handling on manual lifters to large car panels in steel stamping where vacuum cups dominate the stamping process.

COBOT End of Arm Tooling : Collaborative robots, or “COBOT,” have revolutionized industrial automation by working alongside factory personnel to streamline processes, improve productivity, and enhance safety. A key component enabling COBOT to excel in pick and place applications is the use of vacuum suction cups in end-of-arm tooling. These versatile devices have become a popular choice, driving efficiency and precision in a wide range of industries.

Collaborative robots have ushered in a new era of automation. These robots are designed to operate alongside human workers, facilitating seamless human-robot collaboration in various tasks. In pick and place applications, COBOT excel at handling repetitive, mundane, or physically demanding tasks, freeing up factory staff for more complex and value-added activities.

At the heart of a collaborative robot’s end-of-arm tooling in pick and place applications often lies a set of vacuum suction cups. These cups are strategically chosen based on the specific application and the type of objects being handled. Here’s how vacuum suction cups enhance COBOT pick and place operations:

Gentle Handling: Vacuum suction cups offer a delicate touch, making them ideal for picking up and placing fragile objects, such as electronics components, glassware, or food items. The ability to handle delicate items without causing damage is a crucial advantage.

Adaptability: Vacuum suction cups come in various shapes, sizes, and materials, allowing them to adapt to a wide range of objects, including flat, curved, or irregularly shaped items. This versatility ensures that a COBOT can efficiently handle diverse product lines.

Easy Maintenance: Vacuum suction cups are generally easy to maintain, with minimal wear and tear when used properly. Replacement is straightforward, reducing downtime and maintenance costs.

The Future of Vacuum Pick and Place Technology

As we gaze into the future, the potential of vacuum pick and place technology seems boundless. Advancements in materials science, robotics, and artificial intelligence promise to further enhance the capabilities of these systems. Here are some key trends and developments to watch for:

Integration with AI: The integration of artificial intelligence (AI) and machine learning into vacuum pick and place systems promises to usher in a new era of adaptive and self-optimizing automation. These systems will learn and adapt to different materials, objects, and tasks, continuously improving efficiency and accuracy.

Industry 4.0 Integration: Vacuum pick and place technology is set to play a pivotal role in the Industry 4.0 revolution. As manufacturing becomes increasingly interconnected and data-driven, these systems will seamlessly communicate with other machines and systems, creating a highly efficient and responsive production environment.

Material Innovation: Materials science will continue to evolve, leading to the development of vacuum cups that can handle an even broader range of materials, including those previously considered challenging, such as flexible and porous materials. There are many existing standard materials but developing materials that can handle millions of cycles rather than thousands will be the biggest development. If not this, than a simplified and fast changeover with a material that is easily recycled would be key.

In conclusion, vacuum pick and place technology, with its diverse array of vacuum cups, has evolved into an indispensable cornerstone of modern manufacturing. Its adaptability and precision have made it an invaluable asset across industries, from electronics and pharmaceuticals to food processing and automotive manufacturing. As we look toward the future, the integration of AI, Industry 4.0 principles, and ongoing material innovations promise to elevate this technology to even greater heights. It’s a journey that will continue to redefine manufacturing, creating more efficient, precise, and sustainable production processes for generations to come.

This article is the opinion of the author, Daniel Pascoe, president of Davasol Inc., an industrial brand management firm. One of Davasol’s clients, Vacuforce LLC, based in Indianapolis, partnered with the author on this article. Contact Daniel Pascoe at dpascoe@davasol.com.