Rough-Terrain Telescopic Forklifts Keep Expeditionary Military Operations Up and Running

DuraForce Pumps from Eaton Equip the RT022 forklifts with reliable, precise control and maneuverability, even in difficult terrain.

Kalmar specializes in port automation and energy-efficient cargo handling. Working to make every move count for its customers, the company has provided cargo-handling solutions to ports, terminals, distribution centers, and heavy industry since the 1940s. Kalmar was looking to build a new telescopic forklift for rough-terrain operations, and needed a durable and reliable ground drive solution for the vehicle.

Kalmar specializes in port automation and energy-efficient cargo handling. Working to make every move count for its customers, the company has provided cargo-handling solutions to ports, terminals, distribution centers, and heavy industry since the 1940s. Kalmar was looking to build a new telescopic forklift for rough-terrain operations, and needed a durable and reliable ground drive solution for the vehicle.

The Challenge

Looking to meet impeccable standards, Kalmar developed the RT022 light-capacity rough-terrain forklift. With a robust lift capacity of up to 5,000 pounds, the machine is compact enough to drive right into a container and features two-wheel, four-wheel, and crab-steering modes. Designed to load and unload ISO containers, which carry supplies and ammunition for military expeditionary operations, the machine required excellent maneuverability on terrain ranging from sand to mud to water. Additionally, the military needed machines with a life cycle of at least 15 years.

The Solution

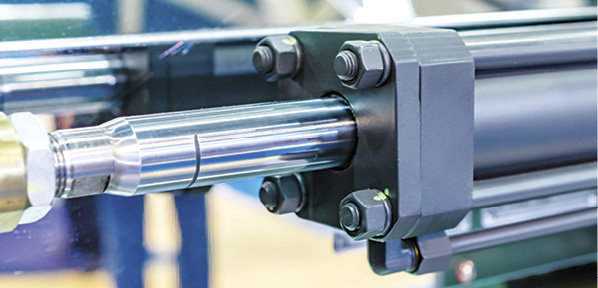

Eaton’s DuraForce HPV pump and HMV motor with CA control provided the RT022 with a robust solution that met the exacting control requirements. The CA control regulates both the pump and motor displacement in accordance with engine speed and operator input, enabling smooth and repeatable vehicle motion through high-resolution control of the pump’s output flow, which in turn is synchronized to the motor rotation speed. Control of the forklift ground speed is predictable and highly reproducible, independent of external factors such as vehicle load and system operating temperature, thus making the forklift easy to use for skilled and novice operators.

The CA motion control of DuraForce has demonstrated notable vehicle-positioning advantages in low-speed conditions, as well as increased productivity at high rates of operation. Both vehicle level benefits are industry recognized as critical traits for the safe and productive operation of material-handling equipment, such as the RT022. Load and temperature independence provided by the CA control also allows operators to depend on the same vehicle response again and again, regardless of the different terrains, environments, and cargo the RT022 is sure to experience over its working life.

The design of DuraForce begins with the rotating kits, which replace the traditional bronze piston slipper with a steel version. Other design features, including the rigid housing and hydrostatic bearing, can handle extreme duty cycles with peak operating pressures of up to 500 bar.

Eaton delivered both the pump and motor with the CA control as an out-of-the-box solution that saved engineering development time for Kalmar. An electronic controller is not required, so less electrical engineering and no software development is required at the OEM level.

Over the past two and a half years, more than 1,000 RT022s have been deployed, with more on the way. No issues have been reported in the field, and the military has been pleased with the performance and operation of the machines.

For more information, visit www.eaton.com.