System Integrators: An Energy Challenge

I have to admit that I am a little bit skeptical. Now, don’t get me wrong. I am not saying that system integrators don’t know anything about saving energy. In fact, I am convinced that they may be, and certainly ought to be, the most qualified to inject energy-saving concepts into the design and implementation of fluid power systems. My skepticism comes from having spent more than 30 years in sales and application engineering in fluid power using both hydraulics and pneumatics. During that time, I do not recall a single supervisor encouraging me to try and provide the most energy-efficient solution to a problem. Our customers had come to depend on us for fluid power solutions because they generally lacked the expertise to design systems themselves. We usually wanted to supply the best solution, but the criteria that defined “best” did not often include the energy requirements of the system.

Some of us have a tendency to over-design systems that we offer as “robust” or “bullet proof.” The systems work well and last a long time but often with an unnecessary consumption of energy or overly complicated electronic controls. If a 50-hp motor would do the job, then we provide a 75-hp motor. If a proportional control would work, then we choose a servo valve. We love systems that require a lot of system integration because we get to show off the neat stuff in our arsenal.

Some of us would rather make a quick sale or find a quick solution than spend time laboring over the energy requirements of a system because the customer’s energy bill does seem to directly affect our salary. Some businesses are often more interested in a quick, robust, and short-range solution than in long-term energy savings. The urgent often takes precedence over the important.

Our management has recently implemented a serious program for continuous improvement. Included in that program is the use of energy. Any suggested changes in the hydraulic, pneumatic, or lubrication systems need to include the impact on energy and the environment as well as on productivity and efficiency.

I count myself among those who could be classified as fluid power nerds. I know there is a point at which “good enough” is good enough, and it can drive a sales manager or plant manager nuts while we labor on to squeeze the last Btu or SCF out of a system. At the end of the day, there has to be a profit made or a solution found or we will not be able to open the doors tomorrow. What I am trying to get across is that we need to think of energy as an integral part of our system integration.

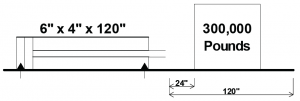

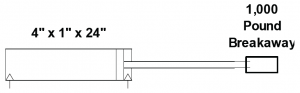

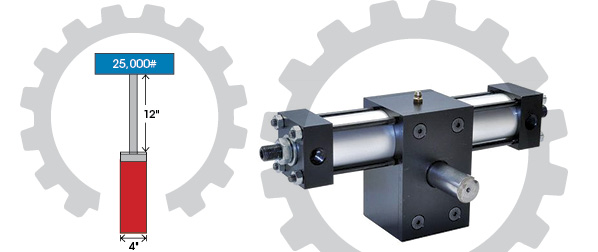

So, here is the challenge. I am going to describe two fictitious fluid power systems, one pneumatic and one hydraulic to see who can come up with the most energy-efficient approach. I am not interested in the lowest price. It is the lowest energy use that is the criteria. The energy standard for hydraulics will be in terms of kWh. The pneumatics system will be rated in Standard Cubic Feet. Feel free to share your proposals with me. I will describe in detail my thought process and the math behind the energy requirements of my proposed circuits soon.

I admit that I have an advantage in that I have had a chance to think about it for some time, but I am not going to use some devious devices or mathematical wizardry to come up with my energy usage. I will only use concepts that have been addressed in my earlier articles.

Are you ready? Here we go!

Take the challenge. Make energy consumption a part of your system integration planning. We can show that Fluid Power Professionals are indeed Energy Professionals.