The Tilting Table Will Not Fully Retract

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training.

Tilting Table

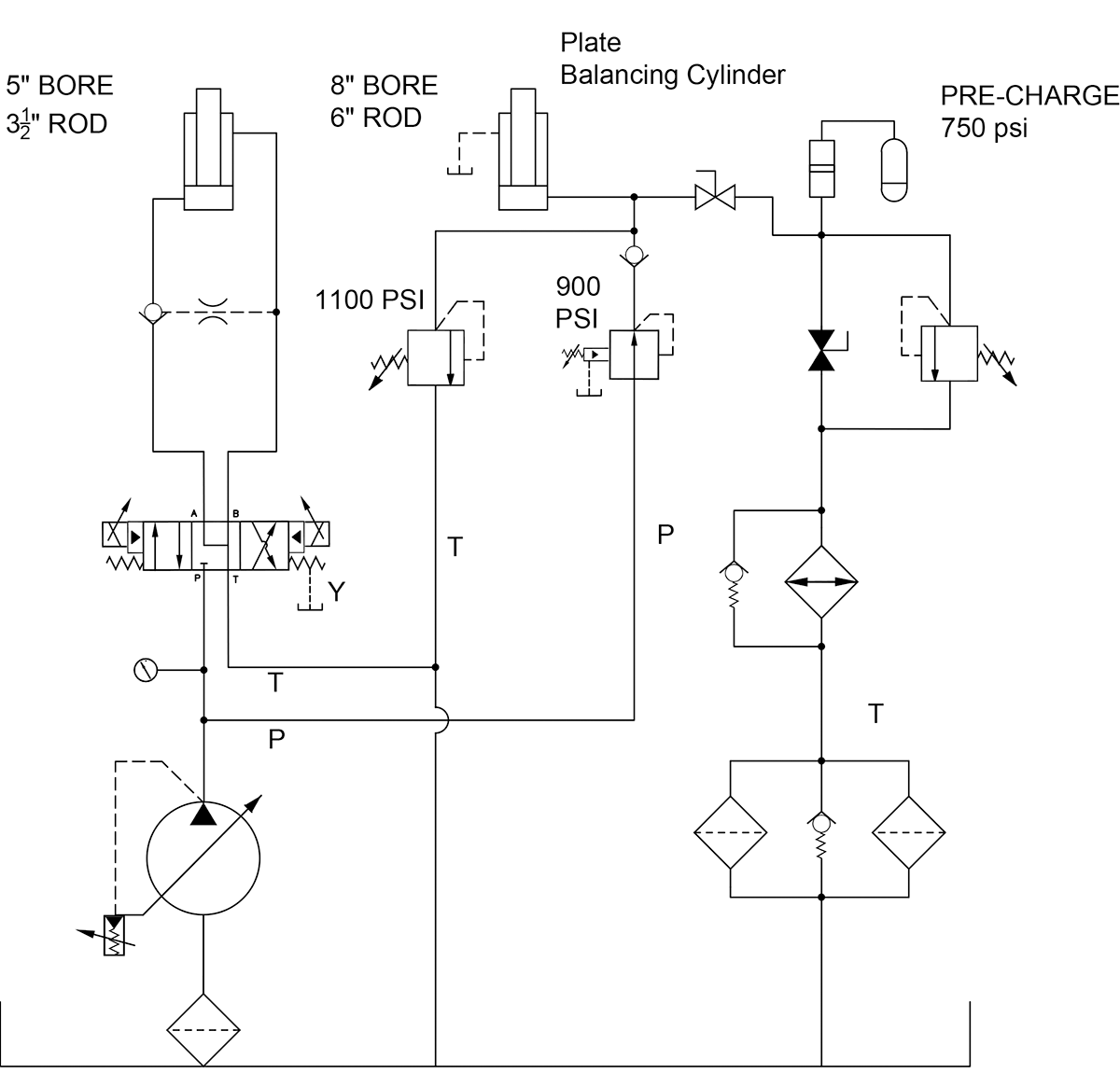

The attached schematic shows a condensed circuit of a steel mill’s “Tilting Table” system. The proportional directional valve extends a 130 mm (5”) bore cylinder at varying speeds and stops when a linear transducer setting is reached. The cylinder that is labeled “Plate Balancing Cylinder” is attached to the same plate and adds lifting force pressure with the prop valve controlling extending speed.

When lowering the table plate, again with the prop valve controlling retracting speed, a retracting force is applied to the plate, helping to push the 8″ bore cylinder down. The exiting oil from the 200 mm (8”) cylinder is pushed into an accumulator, which stops retracting when the 200 mm (8”) cylinder bottoms out.

Four (4) systems like this and three (3) work well while one keeps stopping short of full retraction. When this happens, slightly lowering the accumulator pre-charge lets it bottom out. This is followed by running another cycle 3-4 times a shift with no issue, and then it fails again.

See Solution

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com. Visit fluidpowerjournal.com/figure-it-out to view previous problems.