Vacuum Hose and Fittings

Most applications involving vacuum pick-and-place components utilize small-diameter hose and tubing—the same hose and tubing used on similar-sized pneumatic installations involving connection of valves and actuators, for example. The most common type of tubing used in both of these applications is polyurethane, which is more commonly referred to as simply “PU tubing.”

Polyurethane tubing (Fig. 1) is suitable for small-diameter applications less than 5/16″ (Ø8 mm) internal diameter (ID). Anything larger than this and there is a risk of tubing collapse. Don’t forget that most tubing is rated at an operating or burst pressure, not vacuum. Above 8 mm ID, different tubing should be used. A very popular type would be a wire-reinforced PVC hose (Fig. 2).

This type of hose is rated up to 29.9″Hg with internal diameters of about 2″(50mm). That certainly covers most vacuum applications. If larger diameters are required to prevent vacuum loss over long distances or for very high flow applications, rigid pipe such as PVC, ABS, or steel would be required.

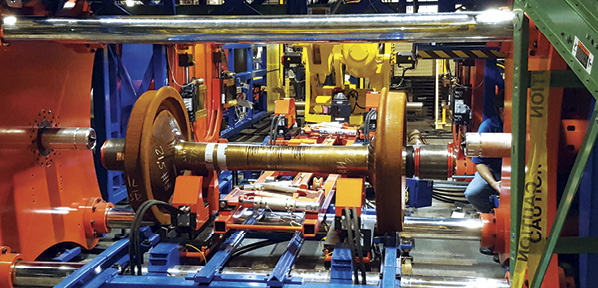

The bend radius of wire-reinforced PVC is also very good, considering the diameter. For example, a 2″ ID hose would have a bend radius of about 5″ (125mm) as shown in Fig. 3. This might be difficult to “thread” through a robot arm, which is why in a lot of cases this vacuum hose that could be attached to a large end-of-arm vacuum tool would be attached to the outside of the robot arm. Not the prettiest, but effective.

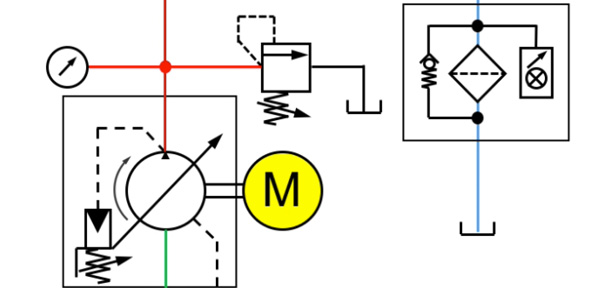

In fact, robotic integrators sometimes choose compressed air venturi systems over vacuum pumps for large vacuum tools purely because of this fact. It’s easier to thread compressed air PU tubing through a robot arm than to use a floor-mounted pump that delivers vacuum through a large-diameter hose. Of course if the tool is one of many that is attached and detached repeatedly via an automatic tool changer, then the integrator has little choice in the matter as there is no auto tool changer, such as the example shown in Fig. 4, that accommodates large-diameter vacuum hose. Not that I have seen, anyway.

So there are a couple of basic choices for vacuum tubing or hose: PU and PVC reinforced with wire. I stress that wire-reinforced PVC is NOT the same as braided PVC hose, as shown in Fig. 5. This will collapse at virtually any vacuum level—a common initial mistake made in choosing larger-diameter vacuum hose.

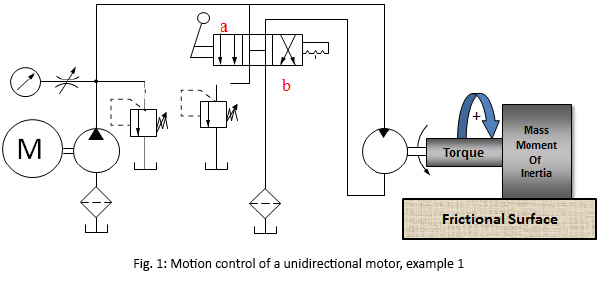

So that’s the tubing taken care of, but how do you connect this tubing to vacuum components such as cup fittings, valves, and so on? Of course nowadays the most popular fitting choice for PU tubing would be a push-to-connect (PTC) or push-in fitting (Fig. 6). Fig. 7 shows a vacuum venturi that also uses PTC technology. However, with PTC fittings, make sure they are suitable for vacuum use. The original designs of PTC fittings sealed better under pressure, which in a vacuum installation does not exist. The PTC fitting used should also be tested for leakage under side load. Good PTC fittings won’t present a problem but ensure that side load-sealing ability is present. The real world offers the real test, after all.

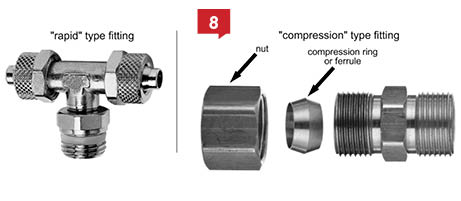

The more traditional fittings, such as “rapid”-type fittings originating from Europe and compression fittings, can be used (as shown in Fig. 8). However, these are very laborious in installation and although, if installed correctly, guarantee a leak-tight seal, the PTC fitting option is certainly faster and less costly. The compression fittings are very much a one-time installation. Once the ferrule is compressed around the OD (outside diameter) of the tubing, it’s permanent. If the fitting is used again, this part of the tubing, including the ferrule, should be discarded.

For larger-diameter hose, the PVC-type described previously is not suitable for PTC fittings. Traditional fittings, such as the hose barb and “worm drive” clip, are the most common and certainly most readily available (as shown in Fig. 9). Of course, there are more fancy and elaborate fittings for larger hose, but as the hose is normally a permanent installation, the hose barb and clip are more than adequate.

Tubing selection is normally determined by what is available onsite at the time of installation. The reason polyurethane tubing is the most popular is because this is normally used in the corresponding pneumatic circuits. For larger hose, this is generally not in stock at the end user or machine builder. When selecting vacuum hose, do not search the Internet for simply “vacuum hose.” You will be digging through vacuum cleaner hose suppliers for hours. Try “reinforced vacuum hose” instead. That should bring up a good list of potential suppliers of the appropriate wire-reinforced PVC mentioned earlier.

ABOUT THE AUTHOR: Daniel Pascoe is General Manager of Vacuforce Inc, a manufacturer and distributor of vacuum components and systems for industry in North America. Daniel can be reached via the Vacuforce website at www.vacuforce.com or directly at dpascoe@vacuforce.com. Find Vacuforce on Facebook and keep updated on Twitter.