Compressed Air System Designs Begin with the Demands

The purpose of an assessment of an existing compressed air system or the design of a new one is to establish sustainable best practices for maximizing the reliability and performance of the system and to minimize life-cycle costs. The desired outcome is to reduce operating costs, product contamination and scrap, and the possibility of environmental damage from the risk of poorly designed systems.

Any new design or recommended improvement should provide direction for the design, installation, operation, and maintenance of compressed air systems. Energy costs alone will generally exceed the purchase price of a compressor in the first year of operation. Less than 20% of the input power to the electric motor is converted to compressed air, and the balance is rejected as heat. Often the highest savings are achieved by addressing the inappropriate application of compressed air and the proper control of the compressed air system.

Compressed air plays a critical role in a very high percentage of industrial applications. Minimum compressed air pressure and quality levels must be established and maintained for specific uses. Obviously, breathing air requires higher quality than compressed air for most packaging operations.

Are there guidelines for use by project managers, facility managers, technicians, and consulting engineers who design, specify, or operate compressed air systems? Will new systems require a different approach than a proposed expansion?

Defining the Requirements – What’s the Use?

Each industry is different, and each plant within any given industry is unique. A new plant will have specific initial requirements, but these will change over time, and anticipated growth should be considered in the initial design.

- Identify and tabulate anticipated end-uses and quantify pressure, rate of flow, compressed air requirements, and air quality.

- Machinery and processes requiring compressed air should be identified by type and the manufacturer’s specified requirements for pressure and flow.

- Plant air for general use also should be identified, quantified, and possibly considered as a separate system from process. Breathing air requires special considerations.

End-Uses – How Much Air is Needed?

Industry end-uses and compressed air requirements should be quantified. Using manufacturers’ specifications, begin with a “demand profile,” which is a form to list each steady demand, including the required pressure and operating flow rates at minimum, average, and peak conditions. Identify and separately list all intermittent demands with compressed air “on/off” cycle times in seconds or minutes. Include the number of shifts and resulting variations and potential future additions.

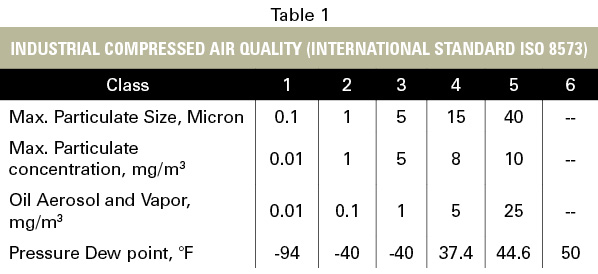

The type and size of compressor required and the quality of the air necessary for the applications are very important factors. The air quality requirement for the applications must be considered as part of the selection of the compressors and the air treatment. An oil-free air compressor may be the specific process or plant standard. Some plants, however, have successfully installed lubricated compressors with proper filtration and excellent maintenance to provide oil-free air. In other cases, plants with almost equal requirements for oil-free air and a tolerance for an acceptable level of lubricant have two separate systems. ISO standards classify the level of particulates, degree of dryness, and amount of lubricant in the air.

Operating at the lowest possible system pressure allows for the most efficient operation. For example, in many compressors, lowering the compressor discharge pressure by 10 psi can reduce specific power (cfm/kW or kW/100 ft3) by 5%. Many plants supply compressed air to the main distribution system at a pressure that is 5-psi above the required minimum, which is determined by either the most significant uses or the one most sensitive to lower pressure.

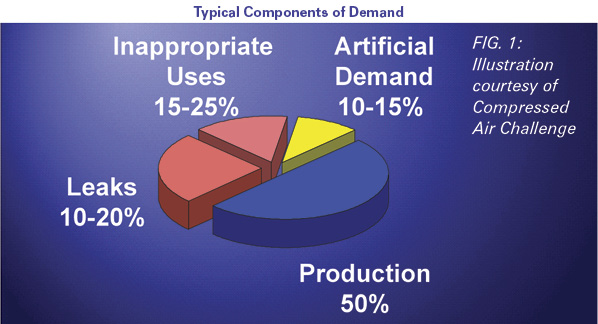

Fig. 1 shows that leaks are typically 10-20% of total demand. Original recommendations were to maintain the leakage rate below 10%; however, compressed air has been recognized as a very expensive utility, and many plants have a standard stating that “leaks should be maintained at less than 5% of peak flow.”

- Artificial demand: increased air consumption required by any unregulated uses due to system pressure in excess of what is actually required.

- “Potentially” inappropriate uses: any application that can be done more effectively, or more efficiently, by a method other than compressed air.

- Leaks: an unintended loss of compressed air to the ambient.

A corollary is to provide automated equipment to shut off air to applications when not in use.

A few end-uses requiring higher pressure can result in the entire system pressure being maintained at an “artificially” elevated level, producing an increased energy consumption. In some plants, end-uses were modified to operate at a lower pressure. In other cases, a motor-driven booster was used for continuous demands or an air amplifier for intermittent uses at higher pressures.

Determining the minimum practical pressure required for an application has brought about the use of low-pressure blowers rather than system-compressed air. There are many examples in plants where a “sparging” process, using compressed air for aerating or agitating liquid, has been replaced with an industrial blower. Depending on the height of column and specific gravity of the liquid, the discharge of the blower was designed to be 4 psig to 15 psig. Assuming 15-psig blower discharge pressure, the energy saved is approximately 60%. In these applications, attention was devoted to determining the possibility of any adverse effects on the process and also the changes to the distribution piping.

Air motors can often be replaced with electric motors, reducing energy consumption by 80%. Similarly, where applicable, replace double-diaphragm pumps with electric motor-driven pumps.

Applying a vacuum pump for continuous-demand applications rather than creating the vacuum with compressed air-venturi methods has been very successful in many industrial applications.

The Quality of Compressed Air

Clean, dry air is defined by the application in which it is used; therefore, compressed air requirements in various industries and laboratories will significantly vary. For most industrial applications, ISO 8573.1:2009 is the international standard for compressed air quality and defines the level of contamination permissible in compressed air (Table 1). The standard identifies three primary forms of contamination in industrial compressed air systems: solid particles, water (vapor), and oil. Contaminants are classified and assigned a quality level, ranging from class 1 (recently class 0), the highest purity level, to class 9.

There are also possible gaseous contaminants. The acceptable level depends on the application, and the purification methods will depend on the specific requirements. It is very important for compressed air users to be aware of what is considered a potential contaminant in their applications, the effects of these contaminants, and the methods to achieve successful and sustainable contamination control.

Process and Laboratory Air

Process air is sometimes defined as air that comes in contact with the product or has incidental product contact. Compressed air must meet minimum requirements of the process equipment that it serves. A minimum pressure dew point of 35ºF to 39ºF supplied by a refrigerated air dryer may not always be suitable. A regenerative desiccant dryer to provide a substantially lower dew point may be necessary, but will consume more energy. Additional filtration may be required depending on the requirements of the air consumer. The additional filters can be located centrally at the compressor or at points of use.

Packaging and Instrument Quality Air

Depending on the end product, packaging air in most plants is defined as air that is used in packaging lines that does not come in contact with the product in any way.

Instrument air is defined as air that is used for instrumentation and controls. Most instrumentation engineers specify oil-free air compressors. Some specifications state that “the compressed air supply shall be oil-free”; this may often be achieved with proper filtration. The pressure dew point of compressed air used within the plant should be at least 18ºF below the factory’s minimum temperature. For instruments used outside the plant, the pressure dew point should be at least 18ºF below the lowest ambient temperatures to which any part of the instrument air is exposed. To monitor these dew points, an alarm is installed to alert operators of a possible problem.

Where instrument, process, and packaging air are all required from one system, use the highest-quality air required for the system. In many process plants, two systems have been designed: one for “plant” air, which may not be dried, and one that is generally at a much higher quality for instrument air or some processes. Because of its importance to control processes, many plants will use dry nitrogen as a backup to support the instrument air system. This is especially important when short-duration power interruptions occur and minimum pressures must be maintained for all instruments and valve actuators.

Breathing Air

In industrial plants, air may be supplied to respirators, hoods, and helmets for various applications, and special breathing air systems are installed. Occupational Safety and Heath Administration (OSHA) standard OSHA: 1910:13d applies and requires drying, filtration, and treatment to meet specific levels, including carbon monoxide, with an alarm system.

The Compressed Gas Association (CGA) Standard Commodity Specification G-7.1, Grade D commonly is specified for plant breathing-air systems.

A minimum requirement shall conform to USA OSHA standard 1910.134 (revision effective April 1998). The CSA (Canadian Standards Association) standard CAN3-Z180.1-M85 is also listed. Check to ensure compliance with all local standards.

- Compressed Breathing Air shall meet at least the requirements for Type 1 – Grade D breathing air as described in ANSI Compressed Gas Association Commodity Specification for Air ANSI/CGA-G7.1. The OSHA standard references this specification and is essentially consistent with ANSI.

- Breathing air must also be tested for additional contaminants such as methane, nitrogen oxide, nitrous oxide, halogenated hydrocarbons, and other hydrocarbons. Air that is grossly contaminated or oxygen deficient may lack the ability to be purified to levels that are acceptable for breathing.

Environmental Design Considerations — Air Quality

The inlet air to the compressor should be as cool, dry, and as clean as possible. Clean is defined as a minimum amount of dust and foreign matter. The air cannot contain other contaminating gases such as ammonia, chlorine, sulfur, carbon monoxide, etc., which can affect the compressor, piping processes, and pneumatic system components. Compressed air must be free of corrosive contaminants and hazardous gases.

For lubricant-free positive-displacement-type compressors (screw and reciprocating), lowering the inlet air temperature by 5ºF will improve compressor performance approximately 1%. Where practical, outside air should be considered for many applications. If the inlet compressed air piping is taken from a remote location, such as outdoors or from conditioned plant air, increase the intake pipe one size per every ten feet of length. Do not install compressed inlet piping near cooling tower or exhaust fan discharge, as this could contaminate the inlet air to the compressor. Install an inlet vacuum gauge to monitor the condition of the intake filter if one is not supplied within the compressor.

Adequate compressor room ventilation is essential for heat rejection, but it is not usually cost effective to air-condition the air compressor area. If the compressor ventilation air is ducted out of the compressor room, the total static pressure of the combined inlet and outlet ductwork generally should not exceed 0.12 inches (30.5 cm) of H2O. A ventilation fan installed in the ducting may be required for heat recovery or to address large ducting losses.

Equipment Selection

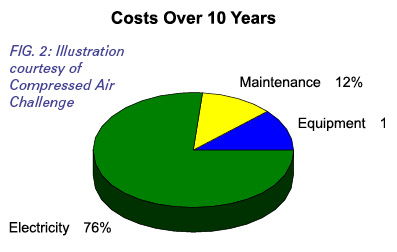

Many companies use life-cycle costing derived from compressed air data and bid response forms. Purchase decisions are often based on factors including actual energy and maintenance costs for a 10-year period, but also on reliability of the equipment (Fig. 2). Requests for proposals may include response forms, which are used to judge among several possible options, including air-cooled, water-cooled, and various types of compressors and ancillary equipment. The data forms could include the following information: package power (kW), pressure, flow (cfm), inlet conditions, dew point for dryers, cooling water or ventilating requirements, service life, and maintenance requirements.

Many companies use life-cycle costing derived from compressed air data and bid response forms. Purchase decisions are often based on factors including actual energy and maintenance costs for a 10-year period, but also on reliability of the equipment (Fig. 2). Requests for proposals may include response forms, which are used to judge among several possible options, including air-cooled, water-cooled, and various types of compressors and ancillary equipment. The data forms could include the following information: package power (kW), pressure, flow (cfm), inlet conditions, dew point for dryers, cooling water or ventilating requirements, service life, and maintenance requirements.

Optimization and Control Strategies

The objective of an effective automatic system control strategy is to match system demand with compressors operated at or near their maximum efficiency levels. The result should be to operate compressors at the lowest possible input power and total energy consumption for all demand conditions. Excessive part-load or no-load operation is wasteful and should be avoided where practical. Variable speed compressor controls are available to minimize wasteful part-load and inefficient operation.

Some examples of multiple compressor sequencing are cascading systems and rate-of-change systems. A cascading system overlaps the pressure setting in the compressors installed so that as the pressure increases or decreases, the appropriate compressor is started or stopped, loaded or unloaded. This type of system generally requires a large pressure band and considerable storage volume.

Today, modern multiple-compressor systems can benefit from sophisticated controls like Smart Sequencers to efficiently match compressor operation and air delivery to the system requirements at the lowest energy consumption. This type of sequencer can be used with any combination of compressor type and manufacturer.

Reducing compressor discharge pressure by 2 psi will reduce input power by 1% for many types of compressors. Proper sequencing controls should consider fluctuations in demand, available storage, and the characteristics of the equipment supplying and treating the compressed air.

Effective control strategies require documented data to monitor:

- Flow measurement (CFM) using mass flow meters that compensate for pressure and temperature variables

- Power and energy consumption, kW and kWh

- Pressure and pressure drop (∆P) before and after major components such as dryers, filters, etc.

- Temperatures. These are often supplied with the equipment.

- Pressure dew point of the system

Another optimization strategy is pressure/flow controllers. A pressure/flow controller is a device that serves to separate the supply side of a compressor system from the demand side of a compressed air distribution system. This controller maintains a constant demand-side pressure with varying demand loads. For this controller to be installed in a system, the supply-side pressure is generally higher (minimum 10 psi) than the demand-side requirement for the controller to work properly. This requires the compressors to operate at an elevated pressure and increase horsepower, but pressure on the demand side can be maintained at a lower stable level to minimize actual compressed air consumption.

Storage, sized to meet anticipated fluctuations in demand, is an essential part of the control strategy. Pressure/flow controllers are an optional system and may not be applicable in many cases. Each compressed air system differs in supply, distribution, and demand aspects that require proper evaluation of the benefits to the system of a pressure/flow controller. Additional primary and secondary air receivers may often be used as an alternative to, or in conjunction with, pressure/flow controllers. Compressed air is a very expensive utility, and the system must be managed to reduce costs.

The electric motor, or any prime mover, inputs power into the compressor shaft, and through the compression process, heat is developed in the air stream. Heat and work are two different methods of transferring energy. It is possible to extract, by heat transfer, an amount of energy from the compressed air that is equivalent to the amount of energy that the electric motor placed into the compressed air. It may be possible to recover almost all the heat generated by the air compressors to significantly reduce a plant’s total energy consumption.

The same strategies and techniques to optimize the operation of the compressed air system can be applied to both new and existing plants. It begins and continues with analyzing the demands.

This was quite the fascinating read since I had no idea that so much thought and consideration had to go into designing a compressed air system. However, I really do like the first question that you ask here about how much air the customer will need in the end. After all, you want to make sure that your air compression system can actually meet your customers’ demands.