Electricity + Hydraulics = Efficiency

By Howard Zhang, Electrohydraulics R&D Leader, Parker Hannifin Corporation.

More companies today are looking to electrify the hydraulic elements of their mobile machines. This trend toward electrification of traditional hydraulic work drives the need to reconsider hydraulic system design to achieve efficiency improvements that maximize battery performance. These efficiency gains are the result of multiple innovations in motor and pump technology as well as controls and system architectures that enable optimal system performance.

Compared to diesel engine-powered machines, where energy storage (in the form of energy-dense diesel fuel) is abundant, battery electric machines store less energy in the same design envelope. This means that battery-powered motion systems need to be designed to maximize efficiency. Even a single percentage point of gained system efficiency can have a significant effect on the machine design and save hundreds of dollars in battery costs as well as reduce weight.

A principal source of system efficiency lies in the conversion of electrical energy to mechanical energy. Electric motor design has a large effect on the efficiency of conversion. Parker’s global vehicle motor (GVM) design, for example, produces one of the most efficient electric machines on the market today. Utilizing a permanent-magnet design with a patented cooling system, the GVM achieves energy conversion of up to 97% efficiency in a comparably compact package, giving machine designers space and weight savings compared to other motor designs. With a variety of system voltages used in the market today, the specific winding design is a key element of energy conversion efficiency.

A principal source of system efficiency lies in the conversion of electrical energy to mechanical energy. Electric motor design has a large effect on the efficiency of conversion. Parker’s global vehicle motor (GVM) design, for example, produces one of the most efficient electric machines on the market today. Utilizing a permanent-magnet design with a patented cooling system, the GVM achieves energy conversion of up to 97% efficiency in a comparably compact package, giving machine designers space and weight savings compared to other motor designs. With a variety of system voltages used in the market today, the specific winding design is a key element of energy conversion efficiency.

One key factor in achieving high overall system efficiency is the choice of a motor winding that operates most efficiently at the required hydraulic pump speed. Permanent-magnet motors have a large change in efficiency over their speed range. Parker’s GVM provides a wide variety of winding options that match the most common voltages and operating speeds.

The next step in energy conversion for an electrohydraulic machine is transitioning the mechanical energy of the electric motor to hydraulic energy from a pump. The ideal selection of the hydraulic pump adequately supplies the hydraulic requirements of the machine while simultaneously minimizing losses.

Selection of pump type, such as piston, vane, and gear pumps, influences efficiency but must be balanced with other design considerations, like initial cost, noise, and pressure and speed limits. Noise in particular takes on additional importance in the absence of a noisy internal combustion engine masking the noise of other system components. Parker’s low-noise gear and vane pumps are good options that balance these often-competing factors for numerous applications and industries. With operational noise levels far below standard gear pumps, high volumetric efficiency, and reasonable acquisition costs, it is an attractive choice for electrohydraulic machines.

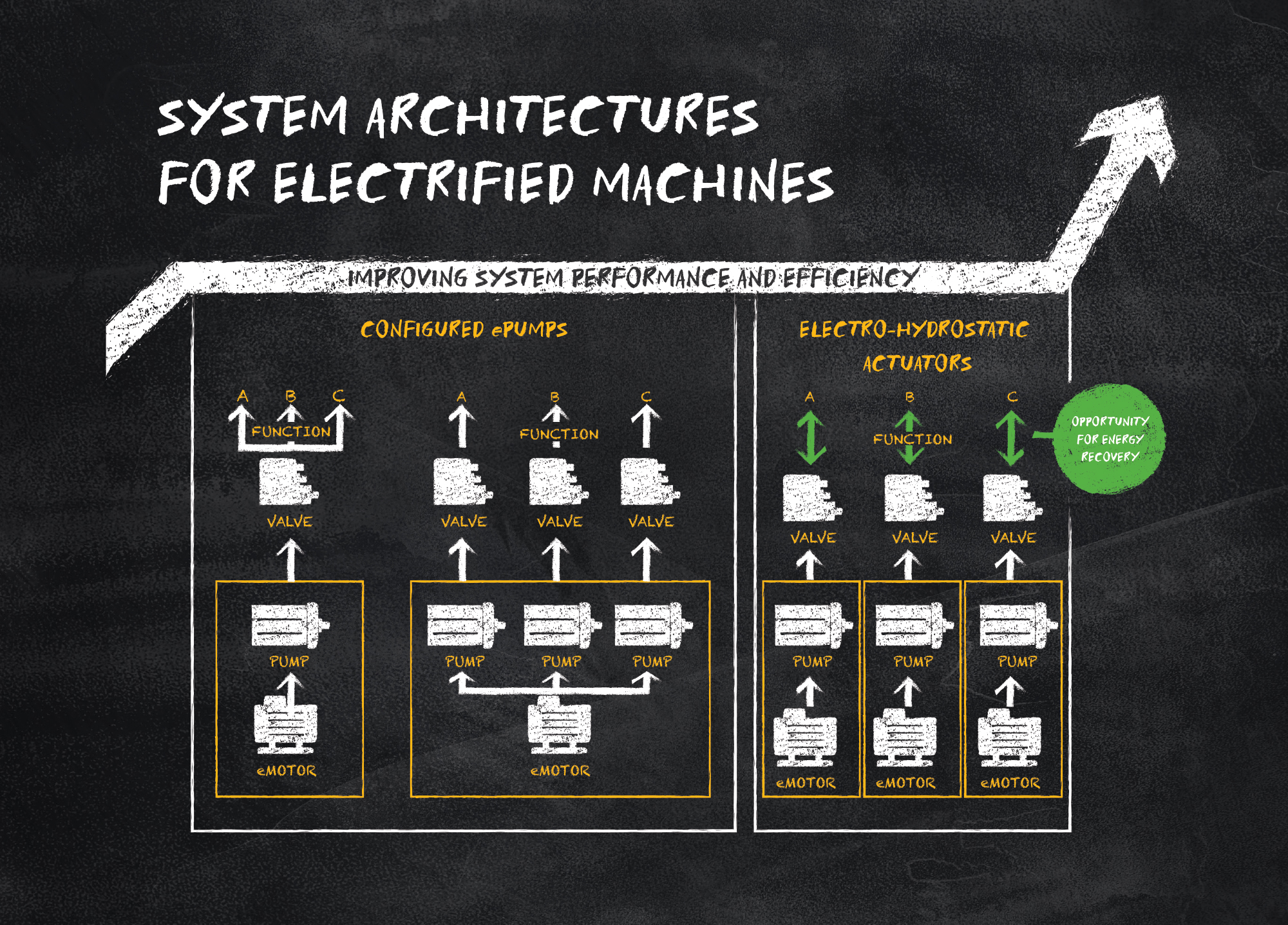

The work system architecture also impacts system efficiency. One option for maximizing energy efficiency and increasing the opportunity for energy recovery is to change the system’s electrohydraulic pump from a centralized system to a decentralized alternative (also known as a distributed electrohydraulic actuation system.)

The graphic on the next page provides a visual explanation. The left side models a traditional hydraulic system in which a single pump supplies pressure and flow to a group of valves throughout a piece of equipment. The right side shows a fully decentralized, optimal efficiency solution in which each function is supplied by an individual motor, pump, and valve.

To achieve the highest efficiency, overproduction of flow or pressure must be minimized. The use of permanent-magnet electric motors offers the added benefit of precise speed and torque control. This control can perfectly match the system flow and pressure to levels required by the current machine operation. This combines with valve spool control to create a flow-on-demand model that achieves simultaneous control of the electric machine speed and the control valve spool position. Minimizing pressure drop across the valve spool minimizes losses in the system, effectively increasing system efficiency. Parker, for example, uses a proprietary control algorithm to help identify the right combination and provides a smooth transition of the operation modes for effectively managing pressure and flow.

An electrohydraulic pump dedicated to a single axis also allows the use of regeneration to recapture energy (shown in the green arrows in the graphic). In the typical hydraulic system on the left, this energy is dissipated as heat through the pressure drop in the valve spool. In the modern decentralized system, the valve can be used for fine metering control, while the pressure drop is kept as stable as possible across the pump. This pressure drop is resisted by torque in the motor, which can return the energy to the batteries through the inverter.

Even using a single motor-pump combination but switching to an electric variable speed motor offers advantages over pumps mechanically driven by traditional diesel engines. Because electric motor RPM and torque vary when compared to a diesel engine, hydraulic system production can be more accurately matched to the exact demands of the system. This also applies when compared to variable pumps that consume significant energy even when at zero stroke due to all the moving elements. The ability to vary the speed of the pump on demand offers a significant efficiency gain.

There are many tradeoffs to consider when designing an electrified hydraulic system to achieve the required performance at a high level of efficiency.

The development of an efficient all-electric or hybrid system is not simply about replacing an engine with an electric motor; rather, it’s about how all the components work together in sync. A hydraulic system must be designed to accomplish the benefits of an electric system while leveraging the inherent advantages of hydraulics. An efficient design configures the system architecture to meet the application requirements and minimize the overproduction of pressure and flow, extending battery range and increasing machine utilization.