Figure It Out: Cargo Ship’s Cylinders Drifted

New Problem

Cargo Ship’s Cylinders Drifted

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training.

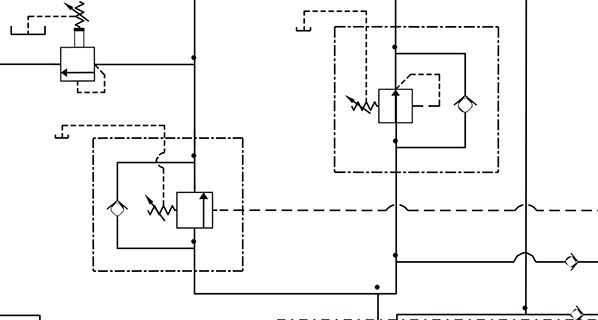

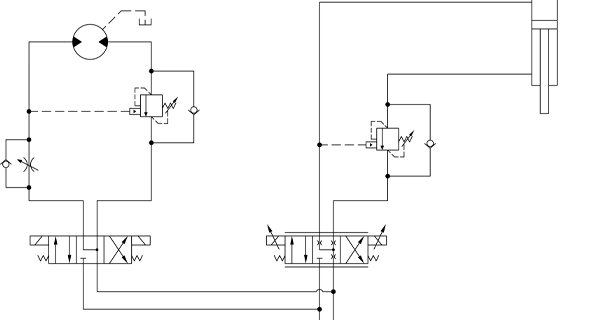

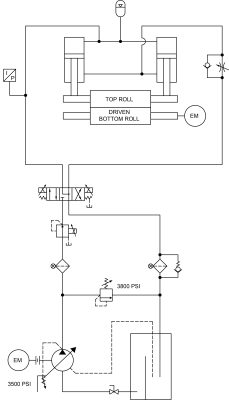

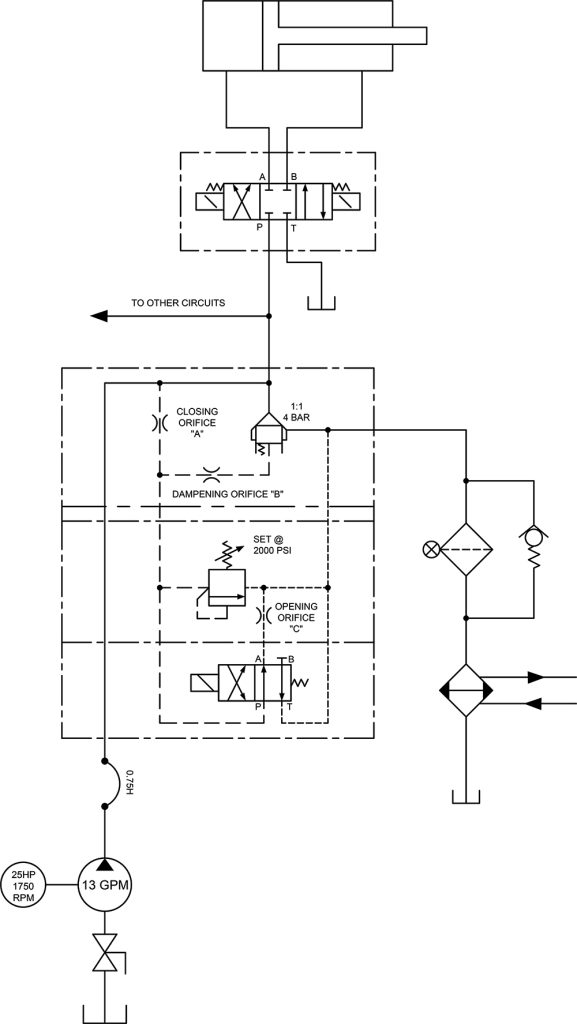

A cargo ship uses a hydraulic power unit to open and close several hatch doors in the grain storage areas. There are eight cylinders and valves located close to eight doors with the HPU on a lower deck. The circuit they attached was the only one they had. All the cylinders were 5-inch bore with 3½-inch diameter rods. Extending the cylinder would open the door.

A cargo ship uses a hydraulic power unit to open and close several hatch doors in the grain storage areas. There are eight cylinders and valves located close to eight doors with the HPU on a lower deck. The circuit they attached was the only one they had. All the cylinders were 5-inch bore with 3½-inch diameter rods. Extending the cylinder would open the door.

Originally, pressing a button for any solenoid energized the solenoid on the unloading valve on top of the main relief and turned on the electric motor. However, someone had rewired the electric motor to run continuously and changed the pump to a pressure-compensated 20-gpm piston.

We found the relief unloading solenoid was energized when the electric motor ran. The pump compensator was set to 2,000 psi while the relief was set to 2,250 psi.

They’re now experiencing a new problem with cylinders drifting out and causing hatch doors to open.

What could be causing the problem?