Large Punch Press Cylinder Stutters On Downward Extension

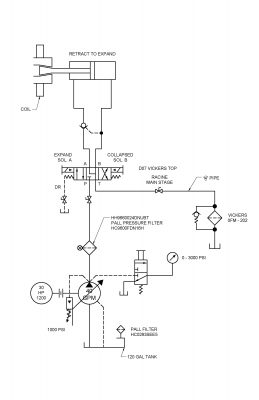

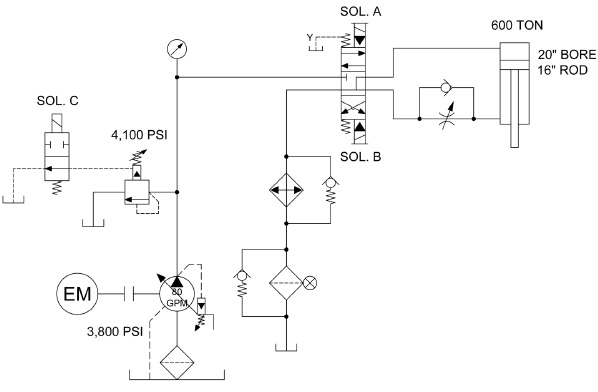

An OEM had a hydraulic distributor design an HPU for a punch press he wanted modified to punch large stainless-steel discs that were then sent to a forming press. The final product was the end caps for cylindrical air compressor tanks.

After the used press was mechanically upgraded they installed the new hydraulic power unit, and during commissioning, they experienced a problem with the ram stuttering on the downward extension, but working just fine on retraction. They could get the desired tonnage at the bottom of the stroke. They also told me the reason for the meter-in flow control on the rod was to slow the cylinders retraction rate due to the high flow going back to tank and that there was dwell time moving the plate stock into its next position.

Another problem was the spool center position needed to be changed so the press could be stopped without the ram wanting to fall to the lower extended position.

See the Solution

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training